Integrated food steaming oven

An integrated, steaming and baking technology, which is applied in the direction of cleaning hollow objects, steam cooking utensils, cooking utensils, etc., can solve the problems of cumbersome manual cleaning of steaming ovens, insufficient heat utilization, and incomplete cleaning, etc. The area of the inner wall of the baking cavity is increased, the flushing degree is improved, and the effect of improving the cleanliness is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

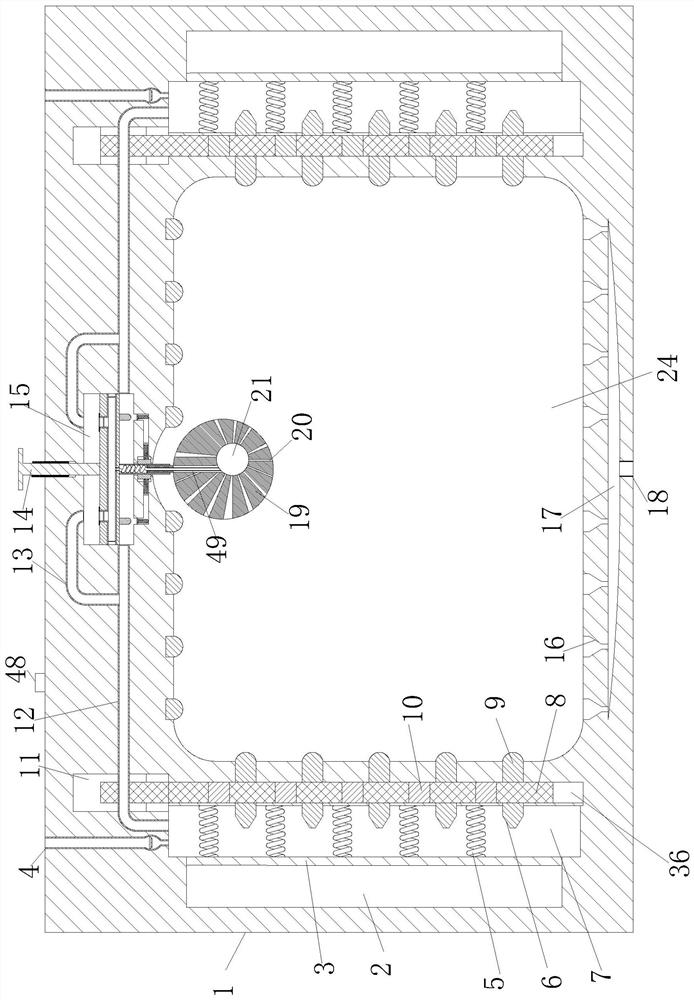

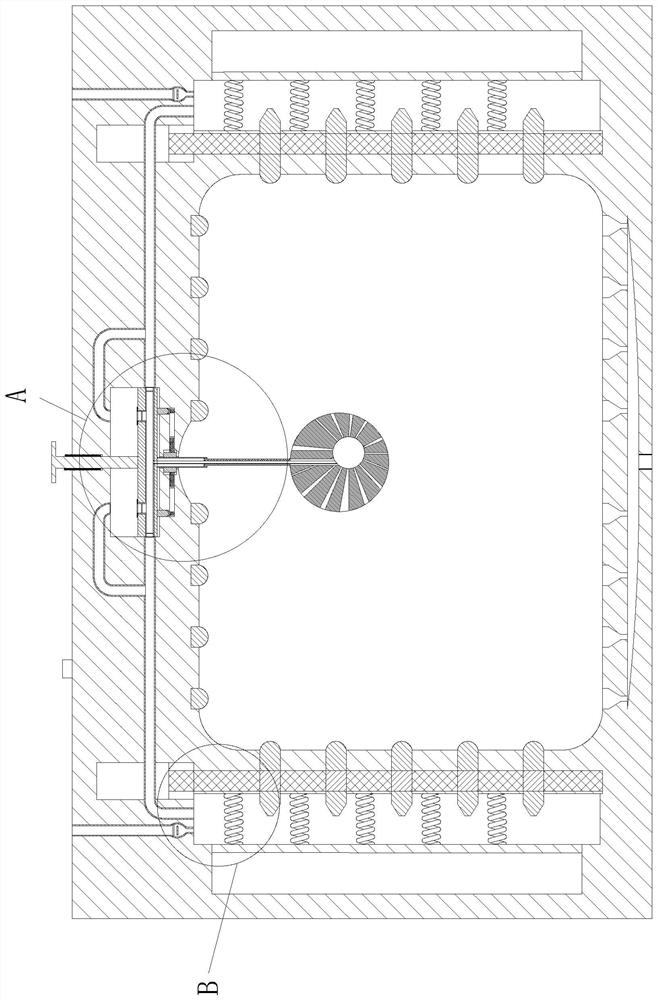

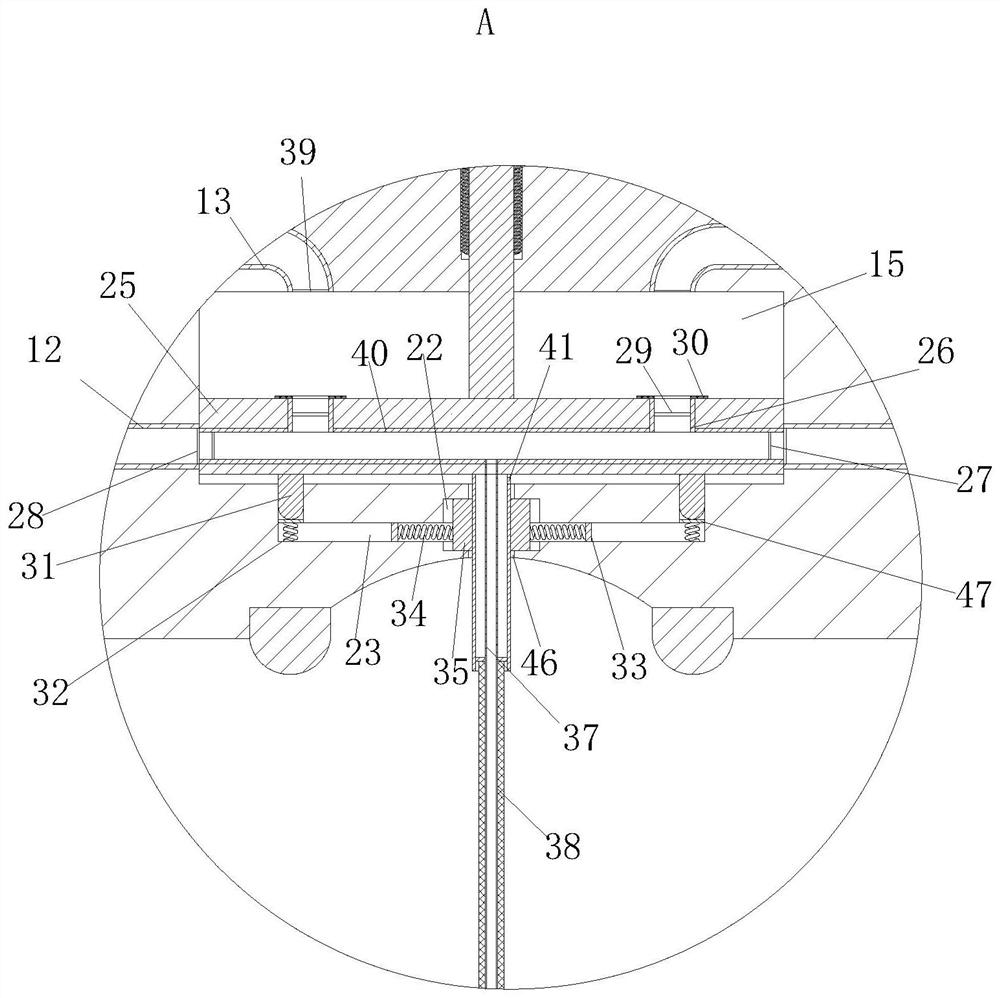

[0039] As an embodiment of the present invention, the air storage cavity 21 in the swinging ball 19 is designed in an eccentric spherical shape; the swinging ball 19 is made of light-weight high-temperature-resistant material; the first through holes 20 are irregularly distributed Inside the swinging ball 19; the inner diameters of the first through holes 20 are different in size;

[0040]When working, the steam enters the air storage chamber 21. Since the air storage chamber 21 is designed as an eccentric sphere, the first through holes 20 are irregularly distributed in the swinging ball 19, and the inner diameters of the first through holes 20 are different in size, so that the outlet of the steam The air volume is not uniform, the steam is sprayed out through the first through hole 20 and enters the steaming cavity 24, driven by the irregularly jetted airflow, the swinging ball 19 is made to swing, and the swinging ball 19 swings back and forth irregularly in the steaming ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com