Integrated precision molding method for metal iridium ventilation window assembly

A technology of precision molding and ventilation windows, which is applied in the fields of metal powder metallurgy and metal welding. It can solve the problems of cumbersome processing of ordinary precious metals, small overall size of ventilation window components, and harsh experimental conditions and equipment, so as to achieve tight combination, tight welding, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

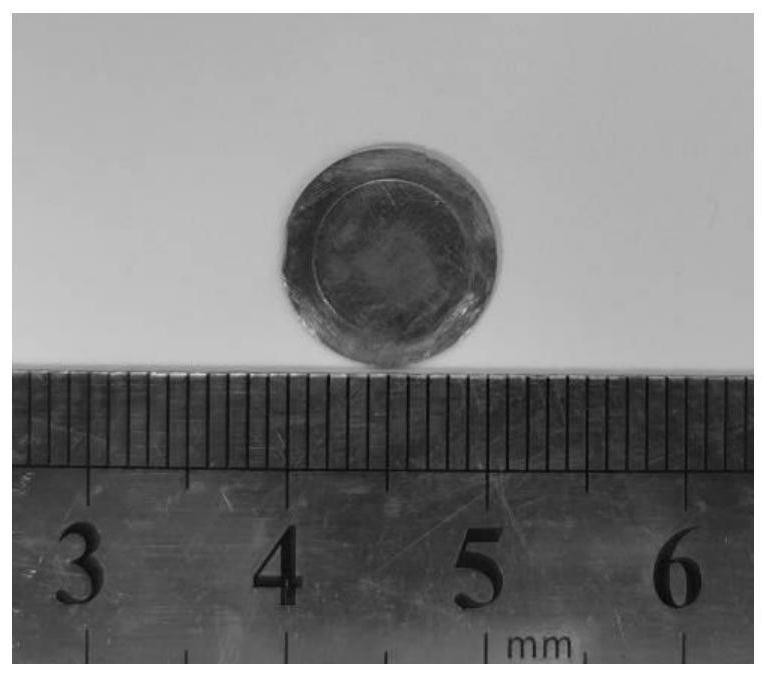

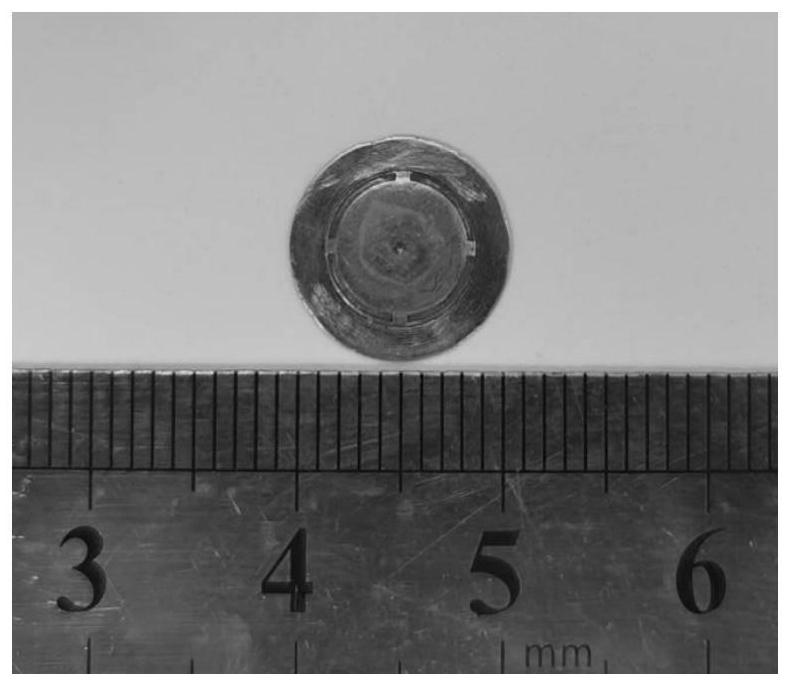

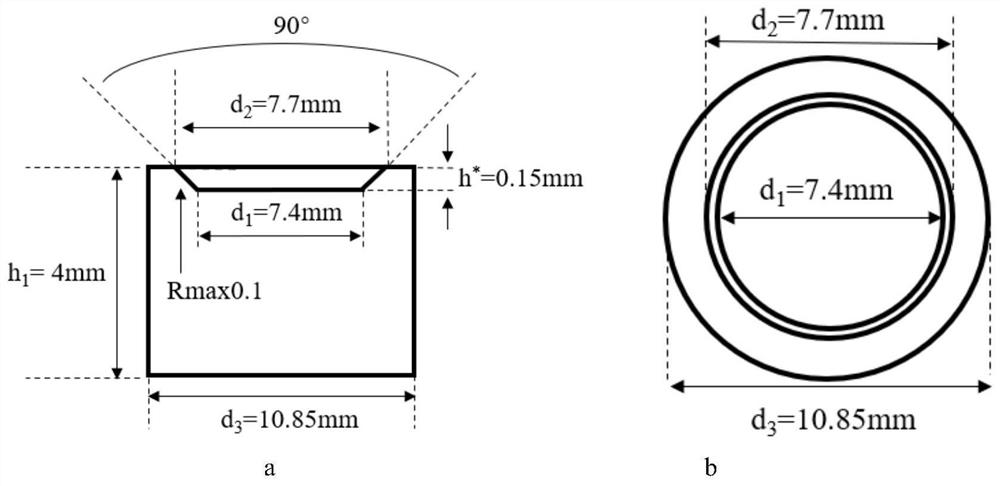

[0054] This embodiment is an integrated precision molding method for metal iridium ventilation window components.

[0055] In this example, a metal iridium vent window assembly was prepared by combining precision graphite mold design, iridium powder filling amount calculation, vacuum hot pressing forming of iridium vent sheet, preliminary diffusion welding and low temperature diffusion welding of metal iridium vent window assembly. Among them, the low-temperature diffusion welding temperature is selected as 1300°C, and the holding time is 2.5h. The specific process is:

[0056] Step 1, calculate the size of the filling area of the precision graphite mold and the filling amount of iridium powder:

[0057] Since the real shape of the parts of the metal iridium venting window assembly is the shape of a truncated cone, the real shape of the iridium vent sheet in the metal iridium venting window assembly is also in the shape of a truncated cone. According to this, the shape and...

Embodiment 2

[0088] This embodiment is an integrated precision molding method for metal iridium ventilation window components.

[0089] The molding process of this embodiment is the same as that of Embodiment 1.

[0090] In this example, a metal iridium vent window assembly was prepared by combining precision graphite mold design, iridium powder filling amount calculation, vacuum hot pressing forming of iridium vent sheet, preliminary diffusion welding and low temperature diffusion welding of metal iridium vent window assembly. Among them, the low-temperature diffusion welding temperature is selected as 1350°C, and the holding time is 2.5h. The specific process is:

[0091] Step 1: Dimensional design of the filling area of the precision graphite mold and calculation of the mass of iridium powder.

[0092] Since the real shape of the parts of the metal iridium venting window assembly is the shape of a truncated cone, the real shape of the iridium vent sheet in the metal iridium venting ...

Embodiment 3

[0120] This embodiment is an integrated precision molding method for metal iridium ventilation window components.

[0121] The molding process of this embodiment is the same as that of Embodiment 1.

[0122] In this example, a metal iridium vent window assembly was prepared by combining precision graphite mold design, iridium powder filling amount calculation, vacuum hot pressing forming of iridium vent sheet, preliminary diffusion welding and low temperature diffusion welding of metal iridium vent window assembly. Among them, the low-temperature diffusion welding temperature is selected as 1400°C, and the holding time is 2.5h. The specific process is:

[0123] Step 1: Dimensional design of the filling area of the precision graphite mold and calculation of the mass of iridium powder.

[0124] Since the real shape of the parts of the metal iridium venting window assembly is the shape of a truncated cone, the real shape of the iridium vent sheet in the metal iridium venting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com