Rapid cooling device for automobile injection molding part

A rapid cooling and injection molded parts technology, applied in the field of automobile manufacturing, can solve the problems of low production efficiency, easy deformation, and deformation of injection molded parts, and achieve the effects of reducing time, improving production efficiency, and reducing the probability of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

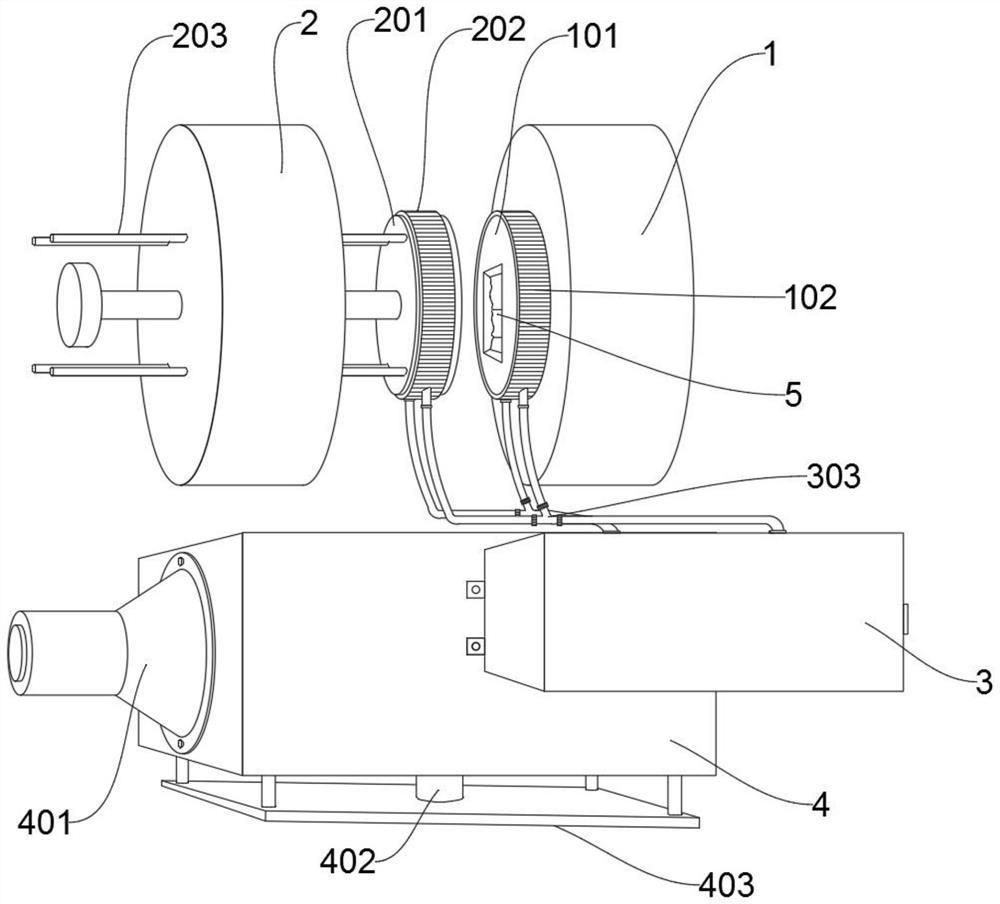

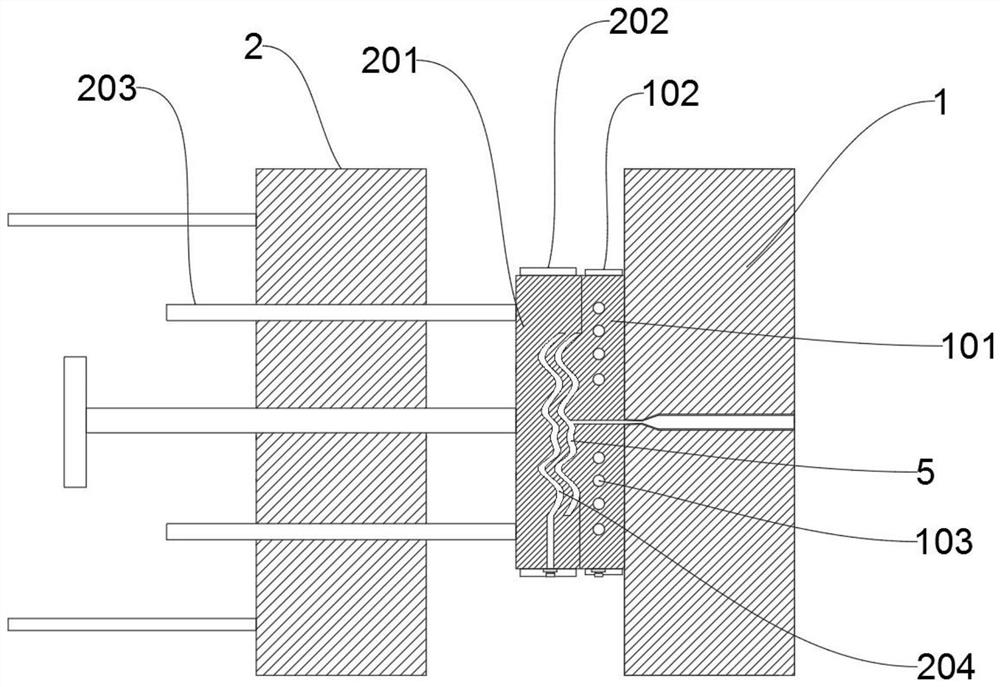

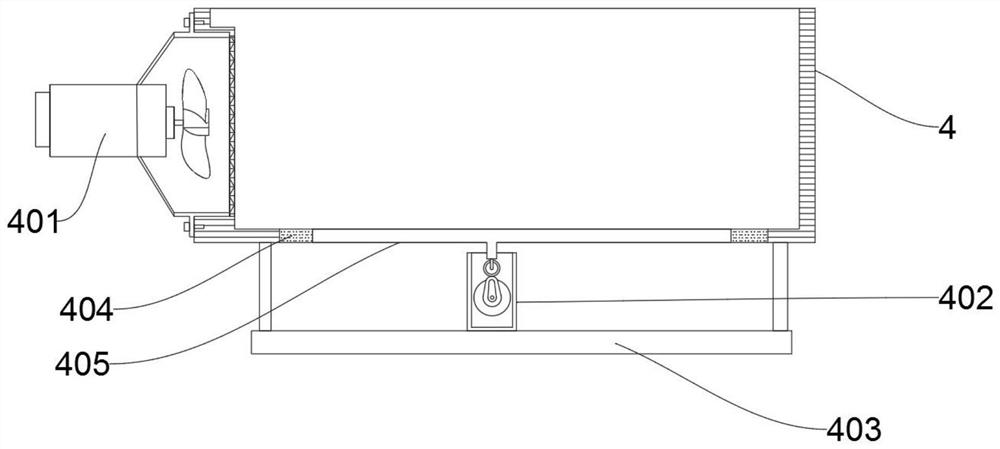

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The present invention provides a rapid cooling device for injection molded parts of automobiles, which includes a feed block 1 and a retaining block 2; the inside of the feed block 1 is provided with a feed gate through casting, and the side of the feed block 1 is fixedly connected with a fixed mold core 101; The curved side of the fixed mold core 101 is provided with heat sink A102 through screw connection; the interior of the fixed mold core 101 is provided with a condensation pipe 103; Extrusion core 201 is connected; the curved side of extrusion core 201 is provided with heat sink B202 through screw connection; cooling bucket 4 is arranged under extrusion core 201; base 403 is fixedly connected to the bottom of cooling bucket 4, and the top of base 403 The surface is fixedly connected with an electric cam machine 402; the side of the cooling bucket 4 is provided with a circulating pump 3 through screw connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com