Spiral spark extinguishing multi-cavity silencer

A muffler and Mars technology, which is applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of large flow resistance and exhaust back pressure of exhaust pipes, large amount of diesel oil used, narrow muffler frequency band, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

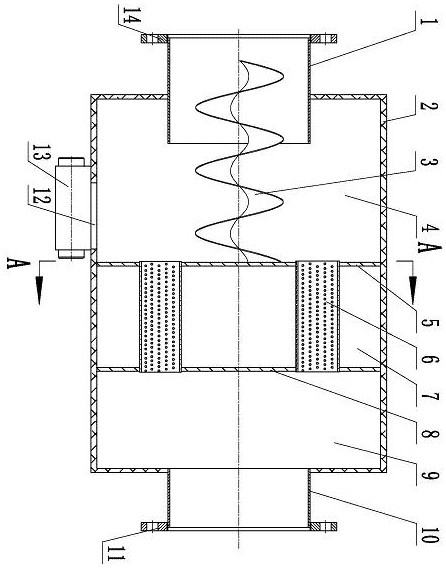

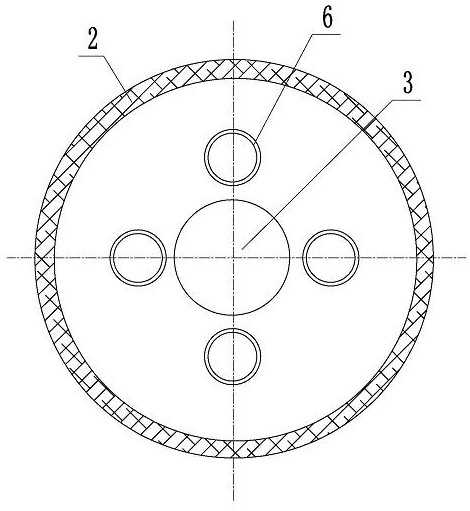

[0019] Such as figure 1 , figure 2 The spiral Mars extinguishing multi-cavity muffler shown in the figure has a cylindrical structure of the muffler cylinder 2. The muffler cylinder 2 adopts a double-layer structure, and the double wall of the cylinder wall is filled with sound-absorbing materials. The sound-absorbing material is rock cotton or fiberglass. The inner cylinder wall of the muffler cylinder 2 is a perforated plate, and the perforated plate is evenly distributed with a number of perforations, the perforation rate is 30%, and the perforation aperture (perforation diameter) is 5mm. There is a glass fiber cloth layer made of glass fiber cloth. An air intake pipe 1 is arranged at one end of the muffler cylinder 2, and an air intake pipe flange 14 is installed on the extended end of the air intake pipe 1; There is an outlet pipe flange 11. Both the air inlet pipe 1 and the air outlet pipe 10 are circular bobbins, and the air inlet pipe 1 and the air outlet pipe 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perforation aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com