A kind of positive photoresist developing solution for flat panel display

A flat-panel display and developer technology, applied in optics, photography, optomechanical equipment, etc., can solve the problems of affecting the interface reaction between the developer and photoresist, affecting the pattern accuracy, and fast developing speed, achieving good application prospects and reducing surface tension. , the effect of suppressing the generation of residues and foam

Active Publication Date: 2022-06-14

福建省佑达环保材料有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The patent with the publication number CN101872136A mentions a general-purpose developing solution containing an alkyl glycoside surfactant, which has good developing precision, but the alkyl glycoside surfactant has rich and fine foams, and a large The accumulation of foam will affect the reaction between the developer and the photoresist interface, resulting in a decrease in yield, so it is difficult to adapt to the currently commonly used high-pressure spraying process

The patent with the publication number CN201110243898.1 mentions a developer solution for OLEDs, which effectively reduces the impact of foam on the process yield by adding fluorine-containing surfactants. Excellent developing effect, but the developing speed of i-line photoresist process and DUV photoresist process is too fast, which will affect the pattern accuracy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

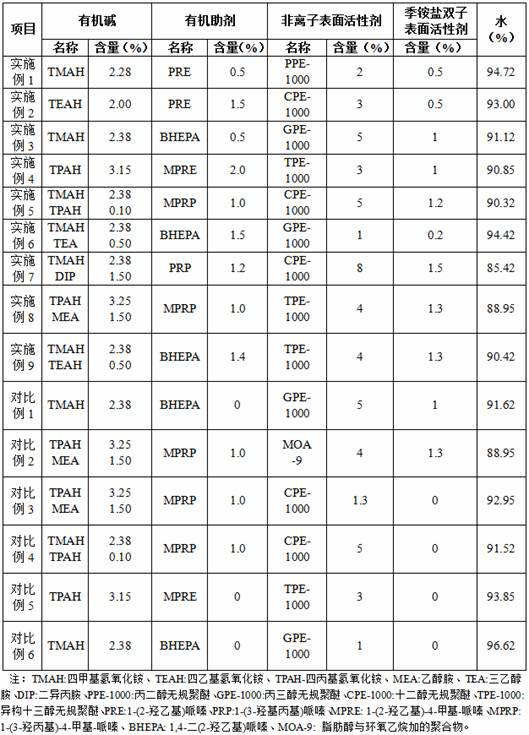

[0024] Table 1 Constituent dosage of positive photoresist developer

[0025]

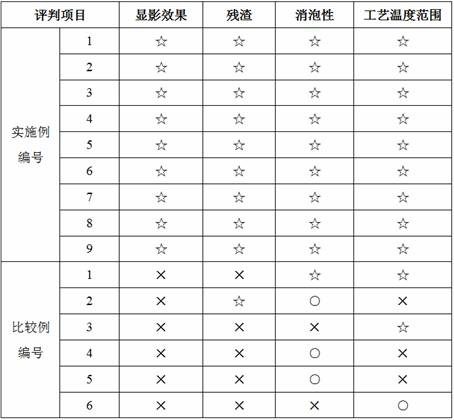

[0026] Performance Determination of Positive Photoresist Developer

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a positive photoresist developing solution used in a flat panel display TFT-array photolithography process. The composition of the positive photoresist developer is organic base 2~5%, quaternary ammonium salt gemini surfactant 0.5%~5%, nonionic surfactant 1%~10%, organic additive 0.5%~2% , The balance is deionized water. In the present invention, by adding the quaternary ammonium base gemini surfactant, the obtained positive photoresist developer has good developability and pattern reproducibility, can effectively improve the yield of good products, and meets the requirements of high-resolution TFT display screens. At the same time, the developing solution has strong dissolving power to photoresist residue, less foam, wide process temperature, and good application prospect.

Description

technical field [0001] The invention belongs to the technical field of flat panel display manufacturing, and in particular relates to a positive photoresist developing solution used in a flat panel display TFT-Array photolithography process. Background technique [0002] In the current flat-panel display industry, TFT-LCD and TFT-OLED are the mainstream technologies. With the continuous improvement of display technology, the precision of photolithography process is also improving. In the Array segment of the LCD and OLED manufacturing process, the positive photoresist needs to be evenly coated on the substrate, then exposed with a mask plate, and then developed with an alkaline developer to remove the unexposed part, and so on for 5 times. -10 times to get the required fine pattern, so it is particularly important to improve the yield of each process. In the development process, the performance of the developer is directly related to the yield of development. At present, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/32

CPCG03F7/322

Inventor 刘小勇田博侯琳熙房龙翔

Owner 福建省佑达环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com