Single frame of amorphous iron core and amorphous iron core

A technology of amorphous iron core and single frame, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, magnetic core/yoke, etc. It can solve the problems of large excitation loss and noise, and reduce labor costs , Solve the problem of sagging and reduce the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0030] The amorphous core is composed of a single frame or assembled from multiple frames. Single boxes are roughly rectangular. Specifically, the amorphous core can be a planar amorphous core, or a three-dimensional amorphous core. The single frames of the planar amorphous core are located on the same plane, and the single frames of the three-dimensional amorphous core are located on different planes.

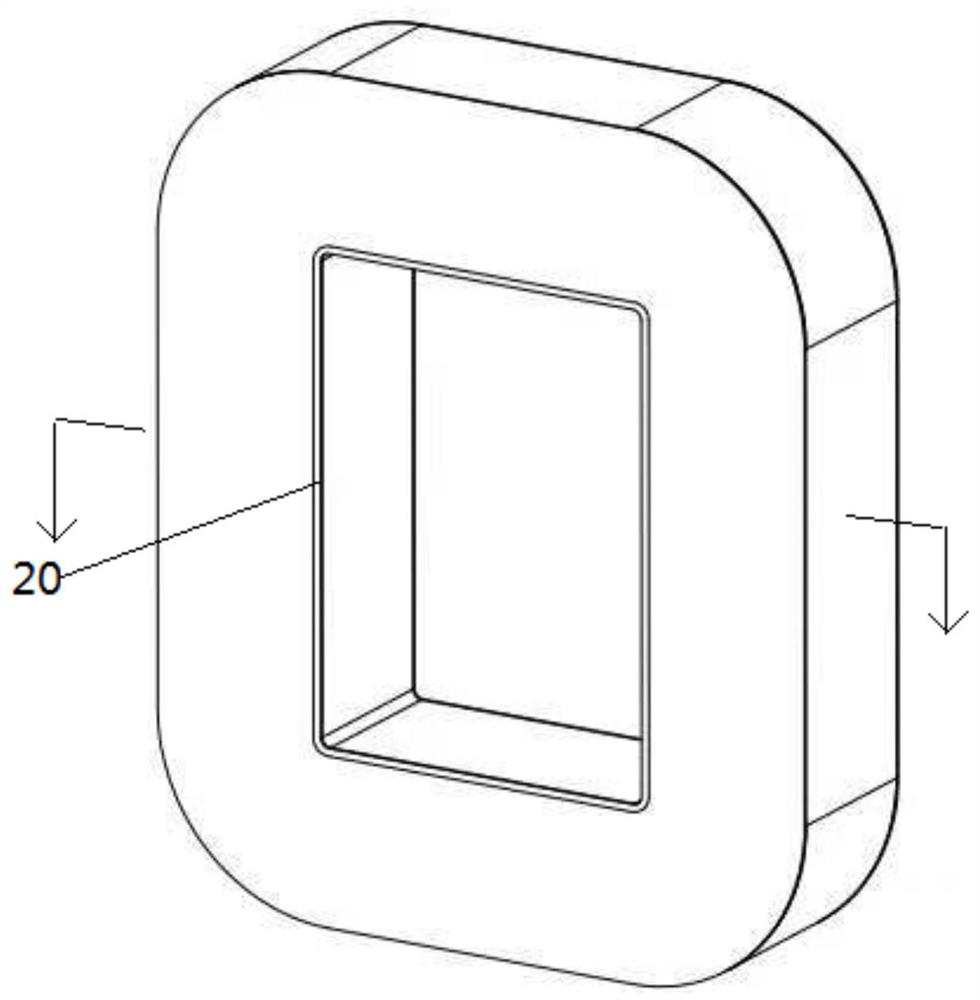

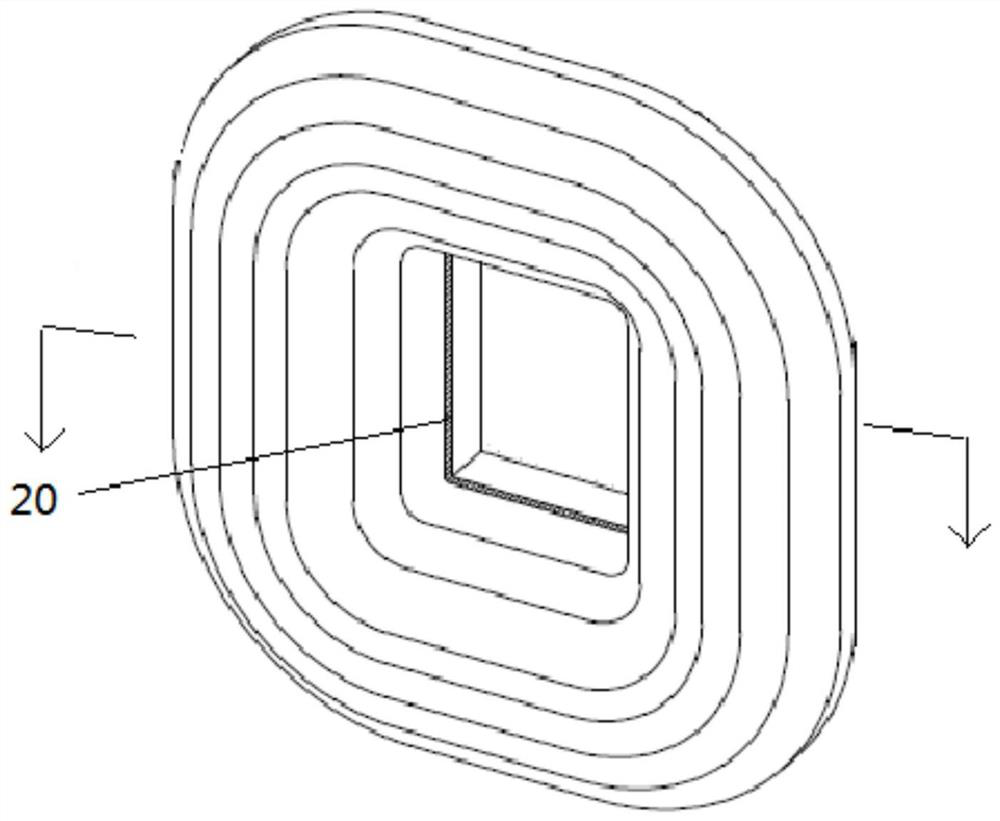

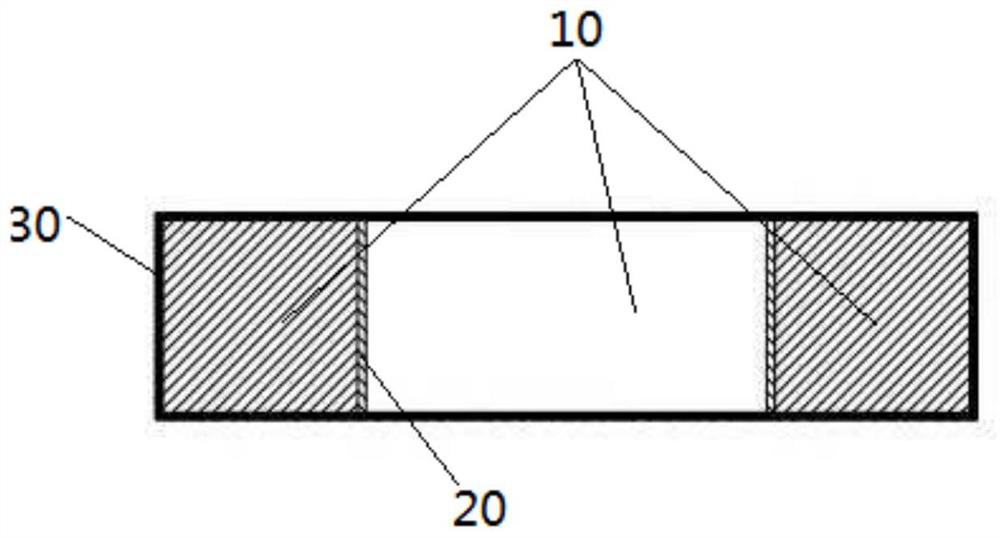

[0031] As shown in the figure, the single frame includes a single frame base 10, and the single frame base 10 is formed by winding an amorphous strip material layer by layer.

[0032] An inner support frame 20 is provided inside the single frame base body 10 . One or more solidified layers 30 are provided on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com