A dust removal device for power system automation equipment

A technology of automation equipment and dust removal device, which is applied in chemical instruments and methods, cleaning methods using gas flow, cleaning methods and utensils, etc., and can solve problems such as inability to achieve dust removal, too many electrical components, cleaning of electrical connections or damage to electrical components, etc. , to improve the dust removal effect, avoid dust scattering, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

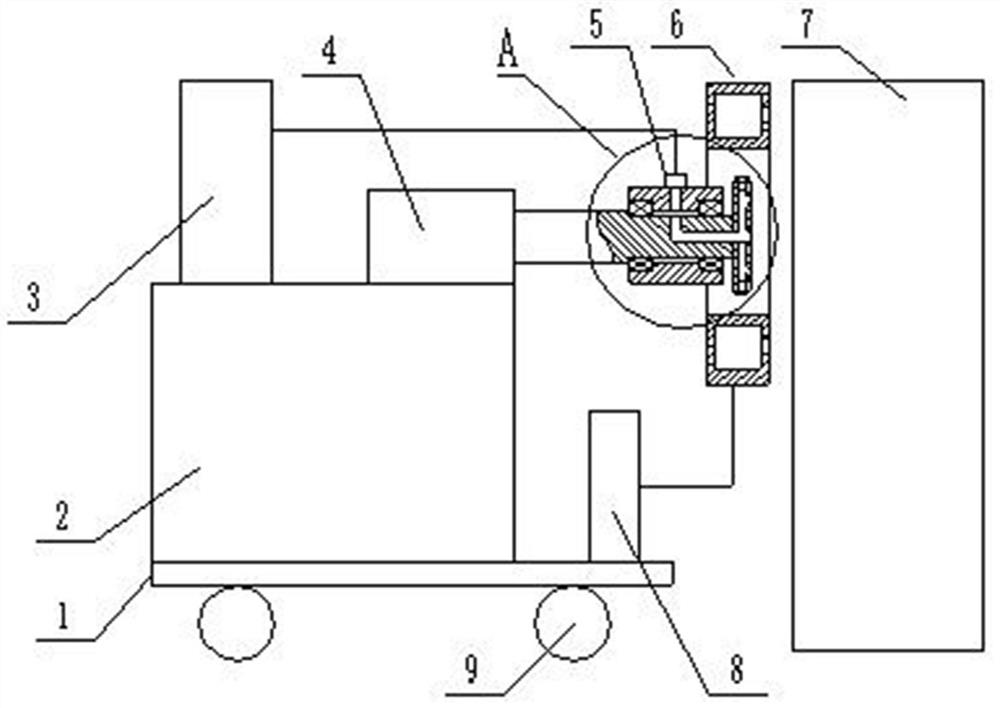

[0037] see Figure 1-Figure 4 shown

[0038] This embodiment provides a dust removal device for power system automation equipment, including a base 1 , a bracket 2 fixedly connected to the base 1 , a high-pressure air pump 3 fixedly connected to the bracket 2 , and a motor fixedly connected to the bracket 2 4. A dust blowing assembly 5 fixedly connected with the output shaft of the motor 4 and a dust removal device 8 fixedly connected with the base 1 ; the dust blowing assembly 5 is in communication with the high-pressure air pump 3 .

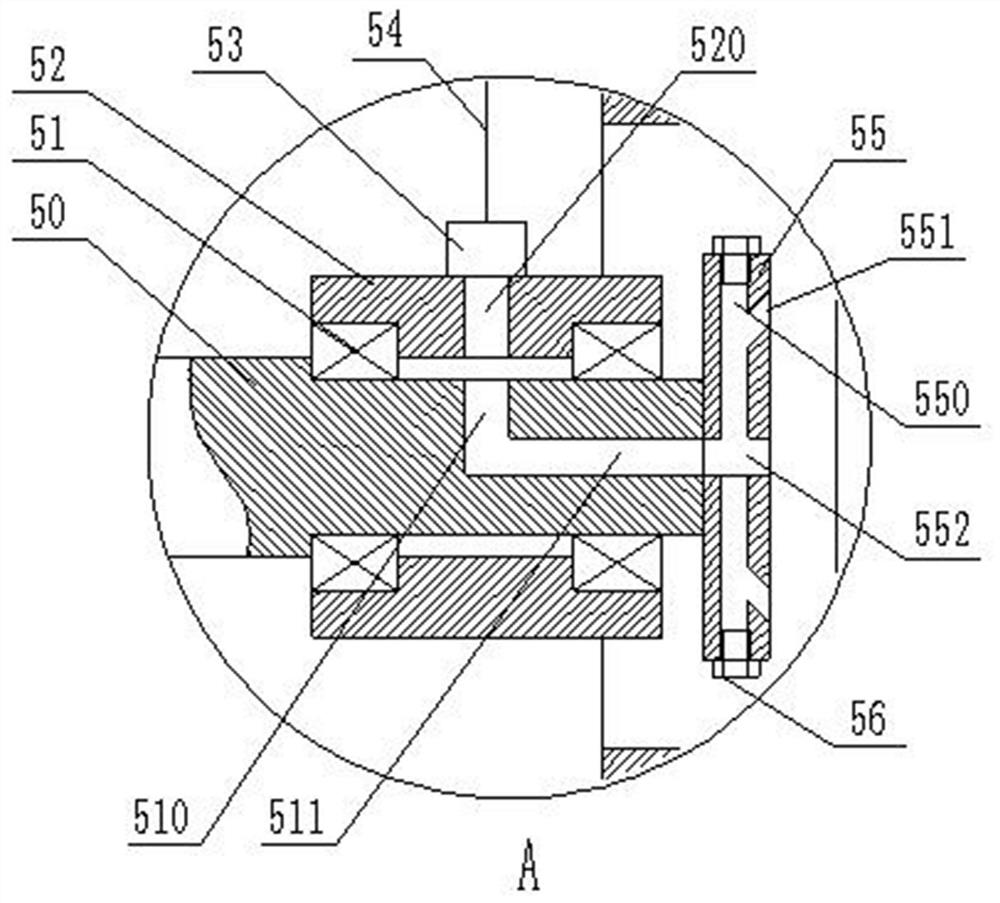

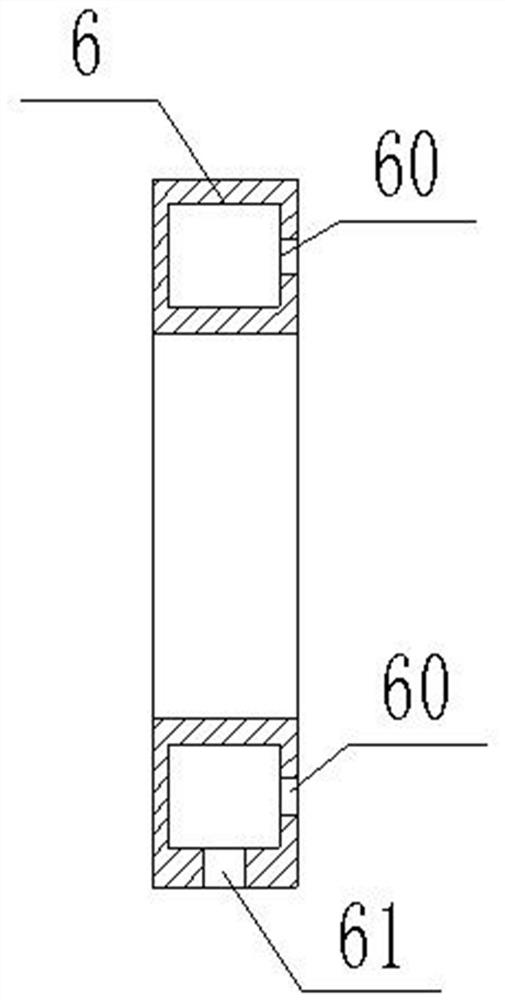

[0039] The dust blowing assembly 5 includes a connecting shaft 50 that is fixedly connected to the output shaft of the motor 4, an air inlet sleeve 52 that is rotatably connected to the connecting shaft 50, a pipe joint 53 that communicates with the air inlet sleeve 52, and a The bearing 51 between the connecting shaft 50 and the air inlet sleeve 52 and the air outlet plate 55 fixedly connected to the end of the connecting shaft 50; the air inle...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, and the similarities are:

[0053] A dedusting device for power system automation equipment, comprising a base 1, a bracket 2 fixedly connected to the base 1, a high-pressure air pump 3 fixedly connected to the bracket 2, a motor 4 fixedly connected to the bracket 2, and the A dust blowing assembly 5 fixedly connected to the output shaft of the motor 4 and a dust removal device 8 fixedly connected to the base 1 ; the dust blowing assembly 5 is communicated with the high-pressure air pump 3 .

[0054] The dust blowing assembly 5 includes a connecting shaft 50 that is fixedly connected to the output shaft of the motor 4, an air inlet sleeve 52 that is rotatably connected to the connecting shaft 50, a pipe joint 53 that communicates with the air inlet sleeve 52, and a The bearing 51 between the connecting shaft 50 and the air inlet sleeve 52 and the air outlet plate 55 fixedly connected to the end of the connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com