A selection method for the application of thermal desorption technology in oil-contaminated soil

A technology for oil pollution and soil heat, which is applied in the selection field of thermal desorption technology for oil-contaminated soil, can solve the problems affecting the comprehensive cost of thermal desorption treatment, and achieve the optimization of high-efficiency oil-contaminated soil thermal desorption technology process, The effect of material balance optimization and optimization development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

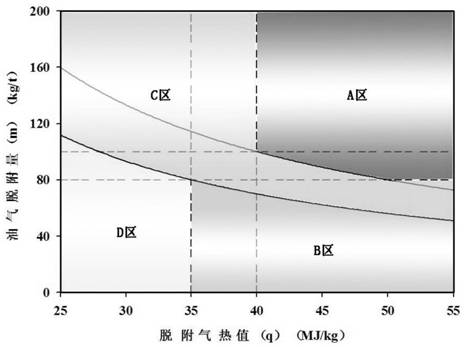

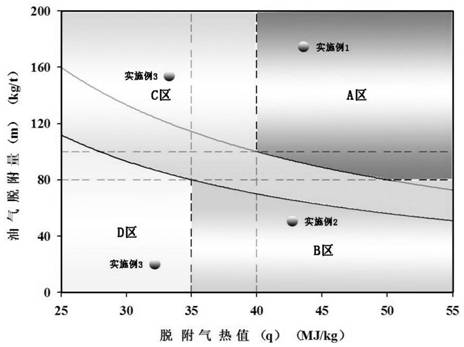

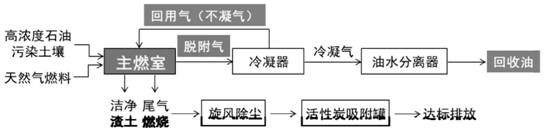

[0030] Example 1 Resource-based thermal desorption application mode of high concentration oil contaminated soil remediation

[0031] In the present embodiment, the high concentration of petroleum contaminated soil to be remedied is an oil content concentration of 17.82% (178.2g ·kg). -1 ), the thermal desorption treatment used is ectopic indirect thermal desorption. First of all, for the high concentration of oil contaminated soil ectopic thermal desorption treatment test, the small test using self-made indirect ectopic thermal desorption equipment, desorption temperature range of 500 ~ 550 °C, thermal desorption material residence time of 35min, thermal desorption treatment discharge, desorption gas through condensation treatment, liquefaction components through oil-water separation determination and recovery of oil content, non-condensing gas components through pressure and temperature measurement and calculation (PV = nRT) to obtain non-condensable gas component content, Thus o...

Embodiment 2

[0033] Example 2 Direct heat reuse type thermal desorption application mode of high concentration oil contaminated soil remediation

[0034] In the present embodiment, the oil content concentration of the high concentration of petroleum contaminated soil to be remedied is 7.01% (70.1g ·kg). -1 ), the thermal desorption treatment used is ectopic indirect thermal desorption. First of all, for the high concentration of oil contaminated soil, the ectopic thermal desorption treatment test is carried out, the small test is carried out by ectopic indirect thermal desorption equipment, the desorption temperature range is 550~600 °C, the thermal desorption material residence time is 40min, after measurement and calculation analysis, the total content of the desorption gas discharge in the main combustion chamber is 50.7kg / t oil-contaminated soil; Collect the desorption gas samples, use the national standard method (GB-T384-81) for the calorific value analysis of the desorption gas samples,...

Embodiment 3

[0036] Example 3 Indirect thermal reuse type thermal desorption application mode of high concentration oil contaminated soil restoration

[0037] In the present embodiment, the oil content concentration of the high-concentration petroleum contaminated soil to be remedied is 16.19% (161.9g·kg -1 ), the thermal desorption treatment used is ectopic indirect thermal desorption. First of all, for the high concentration of petroleum contaminated soil, the ectopic thermal desorption treatment test was carried out, the small test was carried out by ectopic indirect thermal desorption equipment, the desorption temperature range was 550~600 °C, the thermal desorption material residence time was 38min, and after measurement and calculation analysis, the total content of the desorption gas discharge in the main combustion chamber was 153.0kg / t oil-contaminated soil; Collect the desorption gas samples, use the national standard method (GB-T384-81) for the calorific value analysis of the desorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com