Automobile part punching device

A punching device, auto parts technology, applied in the direction of maintenance and safety parts, boring/drilling, drilling/drilling equipment, etc., can solve the problems of surface damage, large pulling force, flanging and other problems of parts, and achieve guarantee The effect of sustainable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

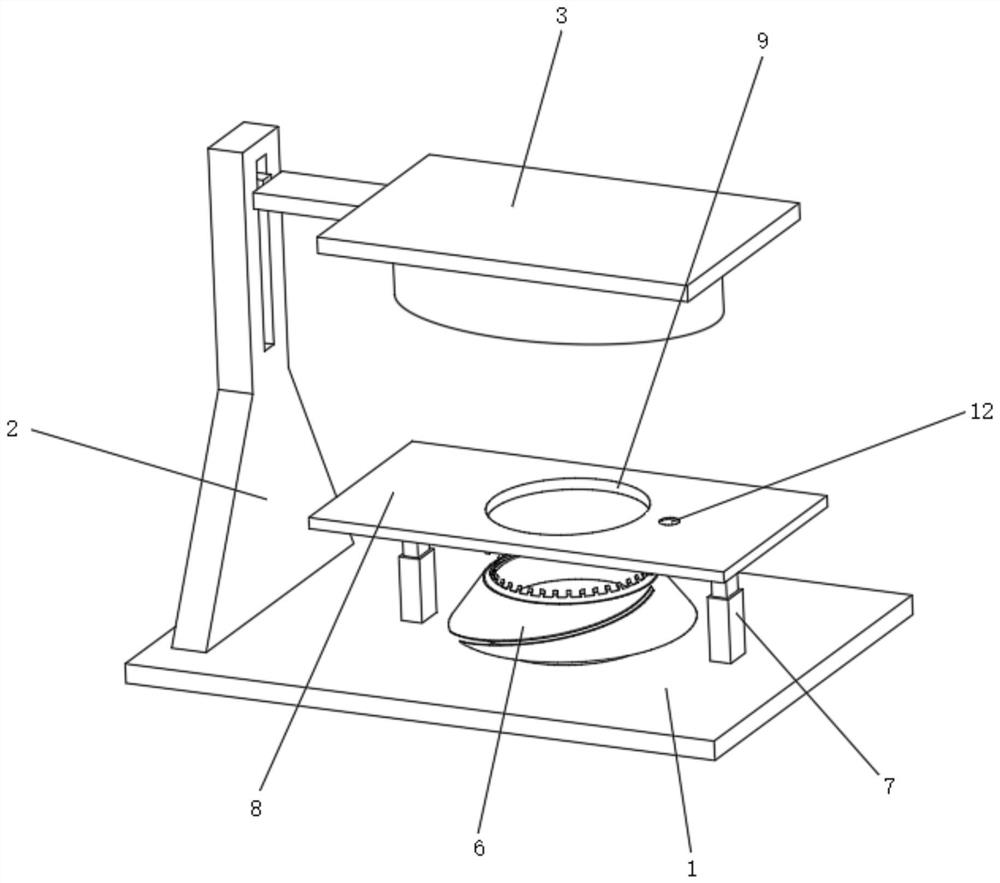

[0038] like Figure 1-3 As shown, the present invention provides a technical solution: a punching device for auto parts, including a punching support plate 1, the left side of the top of the punching support plate 1 is fixedly connected with a travel drive 2, and the output end of the travel drive 2 is fixedly connected There is a punching platen 3, the middle position of the bottom of the punching platen 3 is rotatably connected with a screw-in tool mechanism 4, the bottom of the punching platen 3 and outside the screw-in tool mechanism 4 is fixedly connected with a stable air bag 5, and a punching support plate 1 The middle position of the top is fixedly connected with an auxiliary circumcision mechanism 6, and the top of the perforated support plate 1 is fixed and is fixedly connected with an elastic telescopic rod 7 on both sides of the auxiliary circumcision mechanism 6, and the elastic telescopic rod 7 is far away from the perforated support plate One end of 1 is fixedly...

Embodiment 2

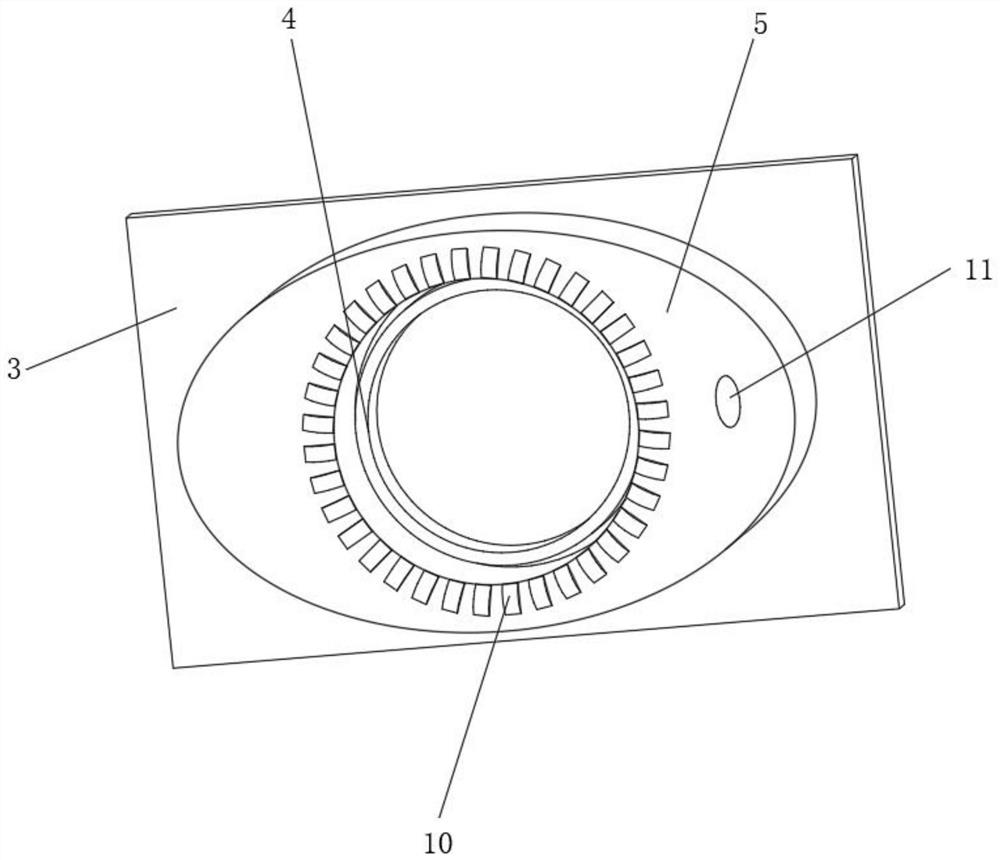

[0044] like Figure 4-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a punching device for auto parts, the screw-in tool mechanism 4 includes a drive limit frame 41, and the top end of the drive limit frame 41 is fixed to the punching platen 3 Connecting, the bottom end inside the drive limiting frame 41 is penetrated and rotatably connected with a transmission drive shaft 42 , and one end of the transmission drive shaft 42 outside the drive limiting frame 41 is fixedly connected with a perforated tooth tube 43 .

[0045] The right side of the drive limiting frame 41 is connected with a conduction tube 45 , and one end of the conduction tube 45 inside the drive limiter frame 41 is fixedly connected with a contact sealing port 46 .

[0046] The outer surface of the transmission drive shaft 42 is uniformly and fixedly connected with a sealing transmission plate 47 . The sealing transmission plate 47 is arranged corresponding to the...

Embodiment 3

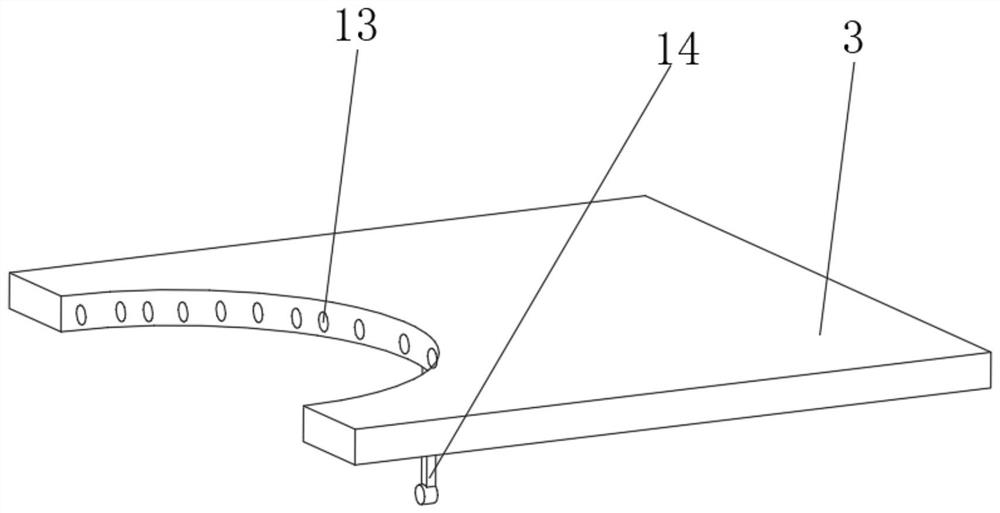

[0049] like Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a kind of auto parts punching device, the auxiliary ring cutting mechanism 6 includes a ring cutting blade 61, and the vertical ring cutting blade 61 outside The position is slidably connected with a driving ring piece 62 , and the top surface of the driving ring piece 62 is evenly and fixedly connected with an auxiliary cutting tooth 63 , which is arranged corresponding to the tooth surface of the perforated tooth tube 43 . By converting the extrusion force into a rotation force, the bottom surface of the fitting is initially scored to achieve the purpose of pre-processing.

[0050] The outer surface of the driving ring piece 62 is provided with a driving thread groove 64 , and the driving thread groove 64 is arranged corresponding to the pressing travel wheel 14 . The fitting is cut along the score to allow the fitting to be punched from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com