Toilet paper glue-free composite embossing process

A technology of toilet paper and embossing, applied in the direction of mechanical processing/deformation, etc., can solve the problems of not taking into account product performance and safety, etc., and achieve the effect of strong three-dimensional effect, good absorption performance, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

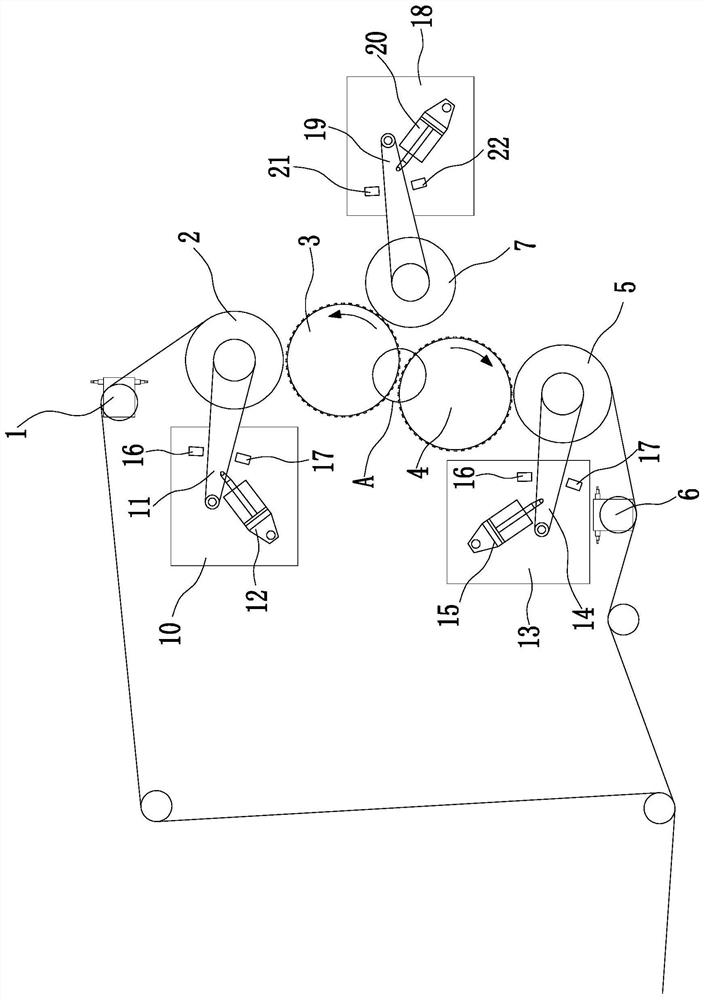

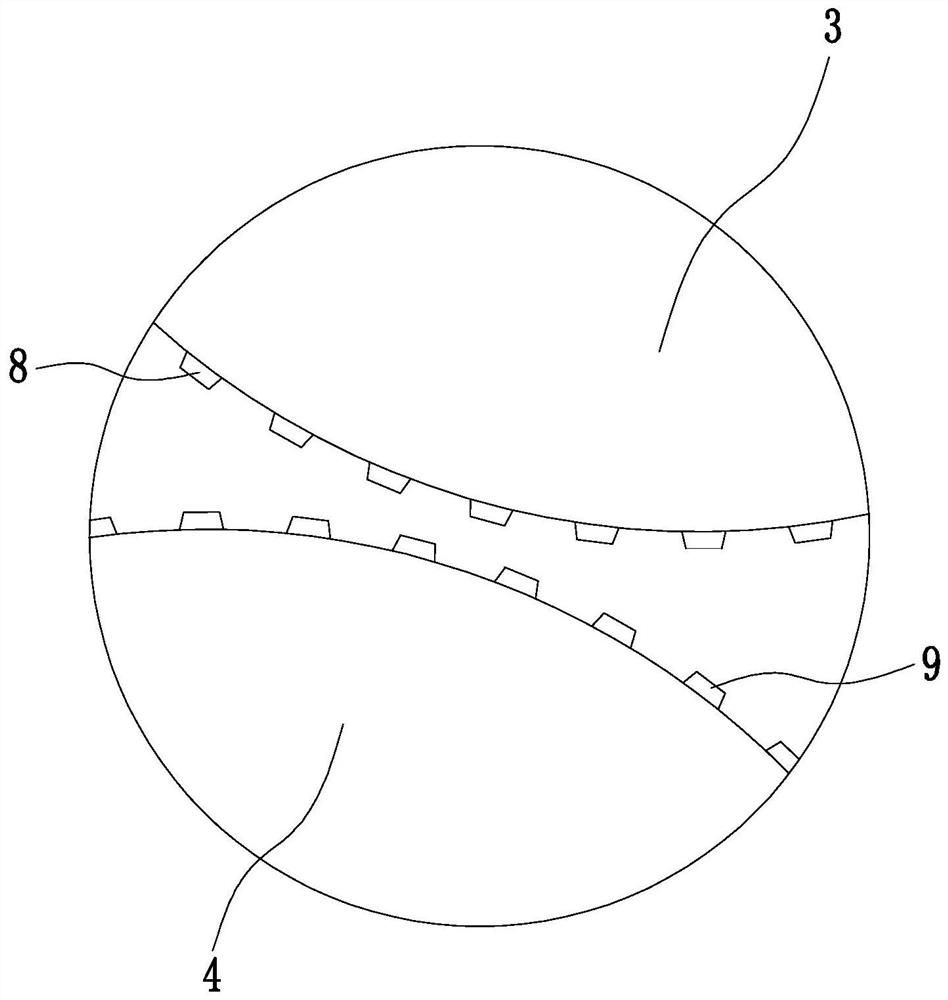

[0033] refer to figure 1 and figure 2, an embossing process for toilet paper without glue compounding, the embossing process is realized using an embossing device, the embossing device includes a first embossing unit, a second embossing unit and a composite roll 7, the first embossing The unit is provided with the first guide roller 1, the first embossing rubber roller 2 and the first embossing steel roller 3 in sequence from top to bottom, and the central axis of the first embossing rubber roller 2 and the first embossing steel roller 3 On the same vertical plane, the second embossing unit is sequentially provided with a second embossing steel roll 4, a second embossing rubber roll 5 and a second guide roll 6 from top to bottom. The central axes of the rubber roller 5 and the second embossed steel roller 4 are on the same vertical plane, and the second embossed steel roller 4 and the compound roller 7 are arranged on the peripheral side of the first embossed steel roller 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com