Rice vacuum packaging system based on intelligent control

A vacuum packaging and intelligent control technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of poor measurement accuracy, need for manual assistance, slow efficiency, etc., and achieve the effect of reliable automation, efficient processing or storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

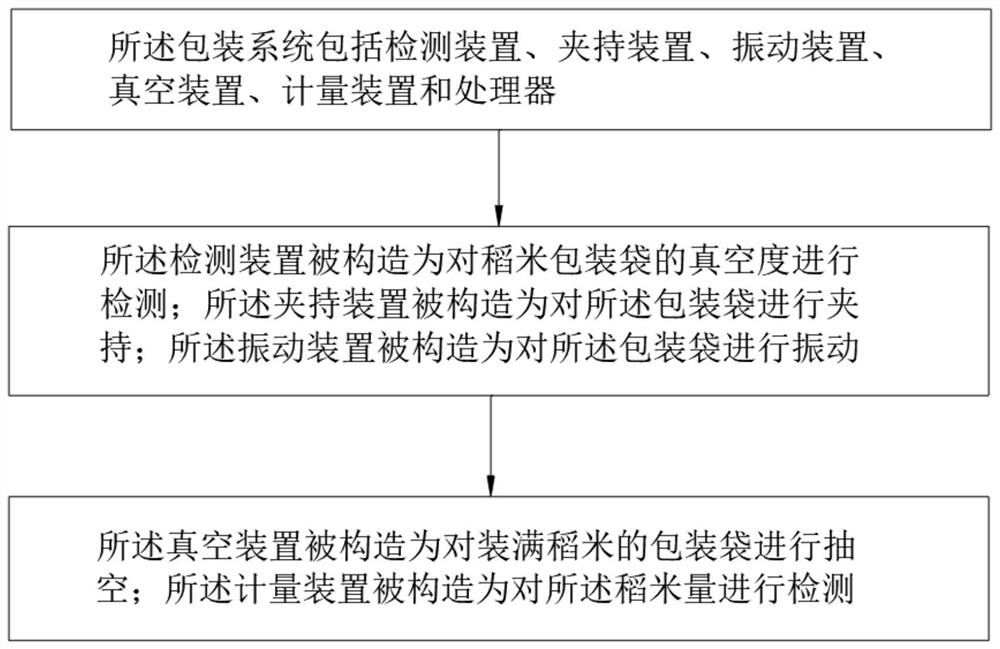

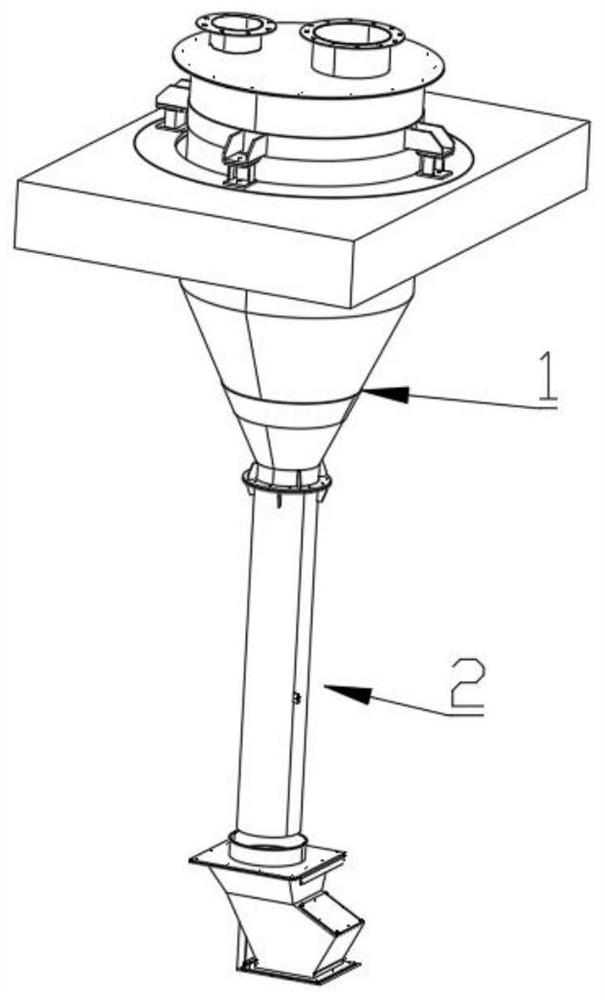

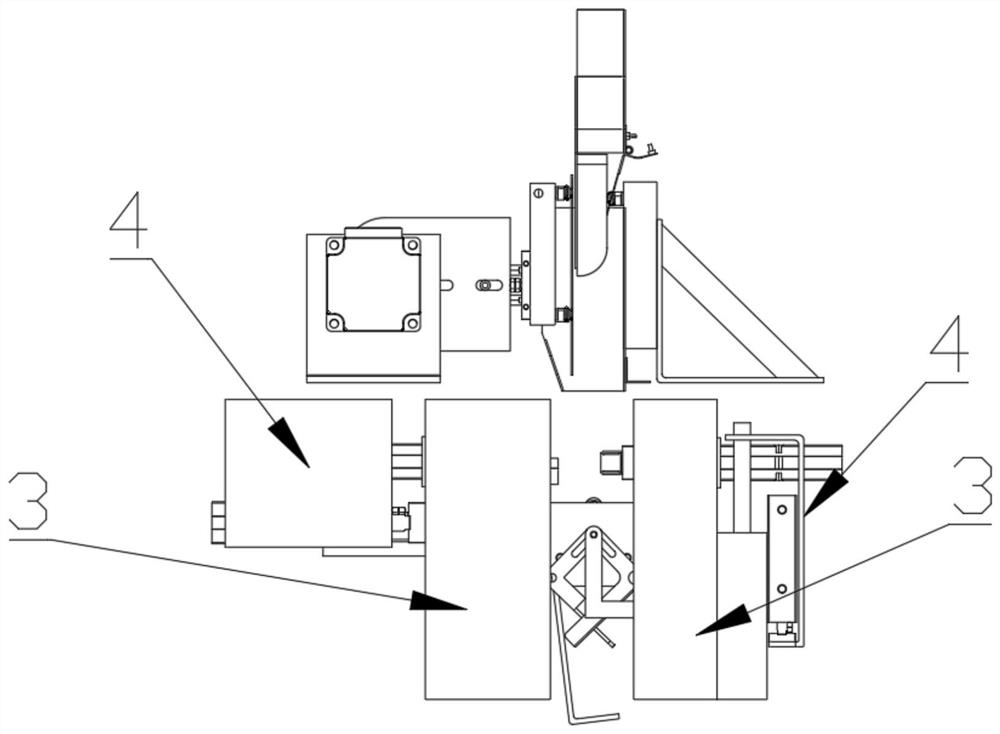

[0032] Embodiment 1: A vacuum packaging system for rice based on intelligent control, the packaging system includes a detection device, a clamping device, a vibrating device, a vacuum device, a metering device and a processor, and the detection device is configured to treat the rice packaging bag The vacuum degree is detected; the clamping device is configured to clamp the packaging bag; the vibration device is configured to vibrate the packaging bag; the vacuum device is configured to vibrate the packaging bag filled with rice The packaging bag is evacuated; the metering device is configured to detect the amount of rice;

[0033]The detection device includes a detection cavity, a detection mechanism and a data collector, the data collector is configured to collect data from the detection mechanism; the detection mechanism is configured to detect the vacuum degree of the packaging bag , and arranged in the detection cavity; the detection mechanism includes a detection piece, a...

Embodiment 2

[0038] Example 2: In order to achieve longer storage time and convenient transportation of existing rice, vacuum packaging of rice is becoming more and more common in real life. Due to its good sealing performance and strong isolation from the outside world, it is more and more favored by merchants Usually, the operator needs to hold the sack of the bag containing rice tightly on the vacuum exhaust pipe, and tie the sack with a rope after the vacuuming is completed. This method is cumbersome and difficult to operate, and is not suitable for large-scale Manufacturing, so there is still room for improvement, there are common problems such as poor automation, poor vacuum, need for manual assistance, poor measurement accuracy and poor sealing performance;

[0039] A rice vacuum packaging system based on intelligent control is provided, the packaging system includes a detection device, a clamping device, a vibration device, a vacuum device, a metering device and a processor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com