2XXX series aluminum alloy and preparation method thereof

A technology of aluminum alloy and master alloy, applied in the direction of metal processing equipment, etc., can solve the problems of low strength and poor toughness, achieve the effect of increasing hardness and strength, improving strength and toughness, and reducing industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In another aspect, the present invention provides a method for preparing a 2XXX series aluminum alloy, comprising the following steps:

[0053] Step 1: Select pure Al, Al-Cu master alloy, Al-Mg master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Zr master alloy as raw materials by weighing according to the mass percentage of each element;

[0054] Step 2: Refining the raw materials to obtain an aluminum alloy smelting liquid, and casting it into an ingot;

[0055] Melt pure Al at 700-750°C, add Al-Cu master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Mg master alloy, covering agent and refining agent in sequence, and conduct a melting to obtain a primary smelting solution , and then add Al-Zr master alloy for secondary smelting to obtain a secondary smelting liquid, which is cooled and left standing at a temperature of 690-710°C for 0.5-1h. Subsequently, cast the obtained aluminum alloy melting solution at 710-730°C, water pressure 0.02-0.05MPa, and speed 40...

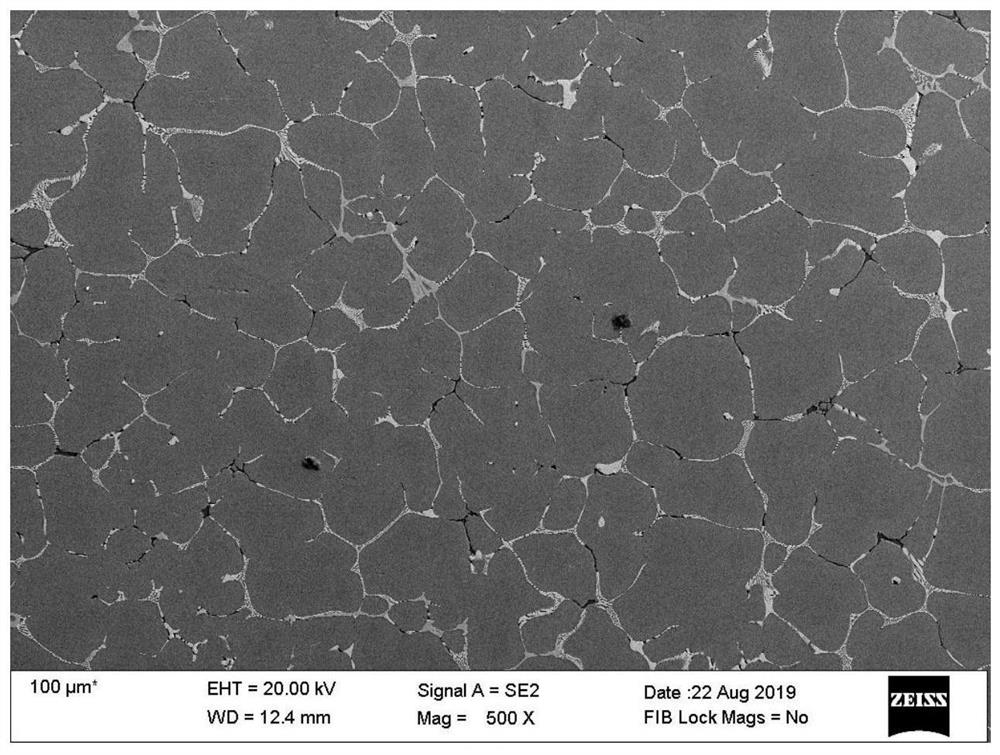

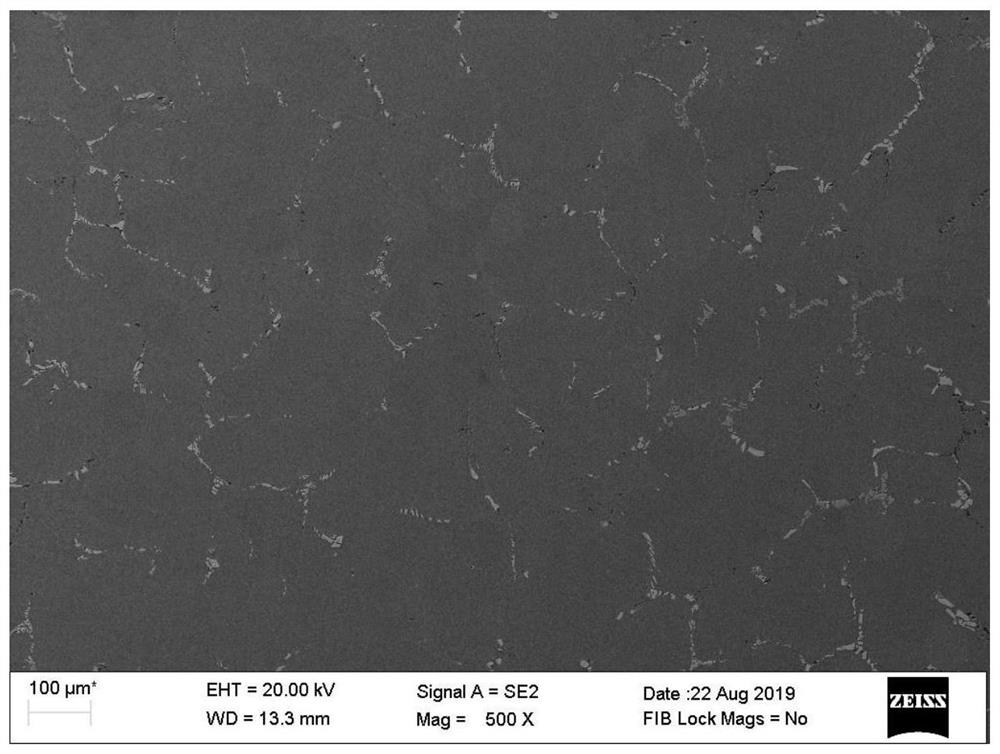

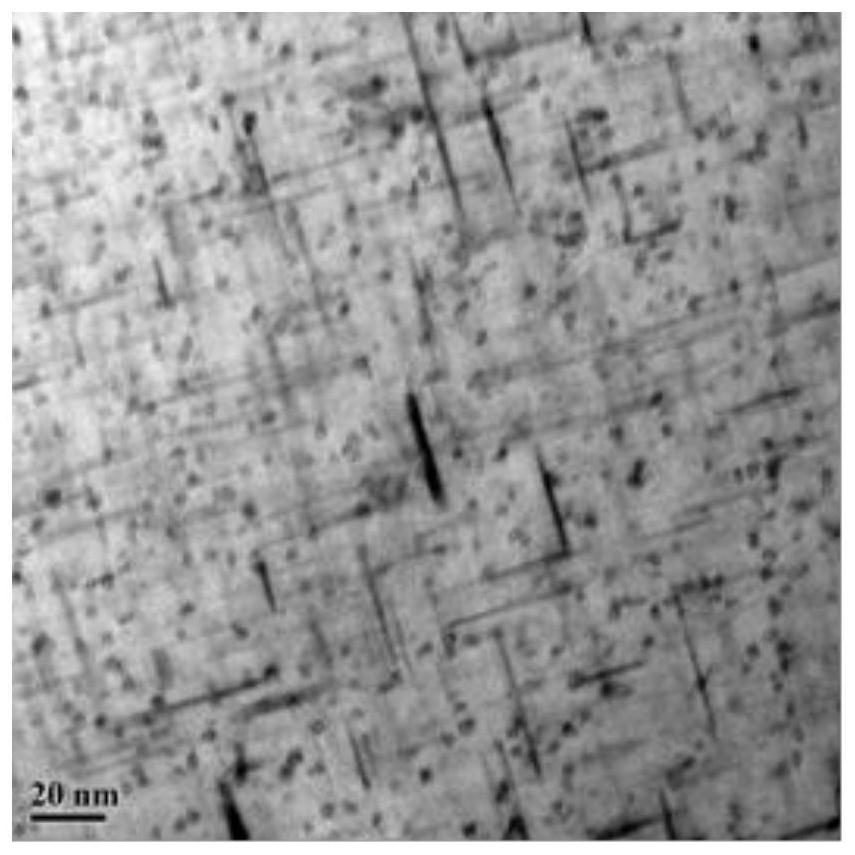

Embodiment 1

[0064] The chemical composition and mass percentage of 2XXX aluminum alloys are: Cu: 4.2%; Mg: 0.73%; Mn: 0.86%; Si: 0.34%; Zr: 0.15%; Ti≤0.1%; Fe≤0.4%; Zn≤ 0.1%; single impurity ≤ 0.05%; total impurity ≤ 0.15%; the balance is Al.

[0065] In this embodiment, the preparation method of 2XXX series aluminum alloy, the steps include:

[0066] Step 1: Select pure Al, Al-Cu master alloy, Al-Mg master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Zr master alloy as raw materials by weighing according to the mass percentage of each element;

[0067] Step 2: After melting pure Al at 740°C, add Al-Cu master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Mg master alloy, expanded perlite and hexachloroethane in turn, and conduct a smelting process. The primary smelting solution was obtained, and then the Al-Zr master alloy was added for secondary smelting to obtain the secondary smelting solution, and the secondary smelting solution was left standing at 690°C for 0.5h. Casting ...

Embodiment 2

[0070] A 2XXX series aluminum alloy prepared from the following elemental components in mass percentage: Cu: 4.5%; Mg: 0.61%; Mn: 0.76%; Si: 0.6%; Zr: 0.15%; Ti≤0.1% ; Fe ≤ 0.4%; Zn ≤ 0.1%; single impurity ≤ 0.05%; total impurity ≤ 0.15%; the balance is Al.

[0071] In this embodiment, the preparation method of 2XXX series aluminum alloy, the steps include:

[0072] Step 1: Select pure Al, Al-Cu master alloy, Al-Mg master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Zr master alloy as raw materials by weighing according to the mass percentage of each element;

[0073] Step 2: After melting pure Al at 740°C, add Al-Cu master alloy, Al-Si master alloy, Al-Mn master alloy, Al-Mg master alloy, expanded perlite and hexachloroethane in turn, and conduct a smelting process. The primary smelting solution was obtained, and then the Al-Zr master alloy was added for secondary smelting to obtain the secondary smelting solution, and the secondary smelting solution was left standing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com