High-hydrophobicity water-based gloss oil and preparation method thereof

A water-based varnish, high hydrophobicity technology, used in textiles and papermaking, fiber raw material processing, paper coatings, etc., can solve problems such as low viscosity of coatings, inability to meet high hydrophobicity requirements for printed products, and difficult application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

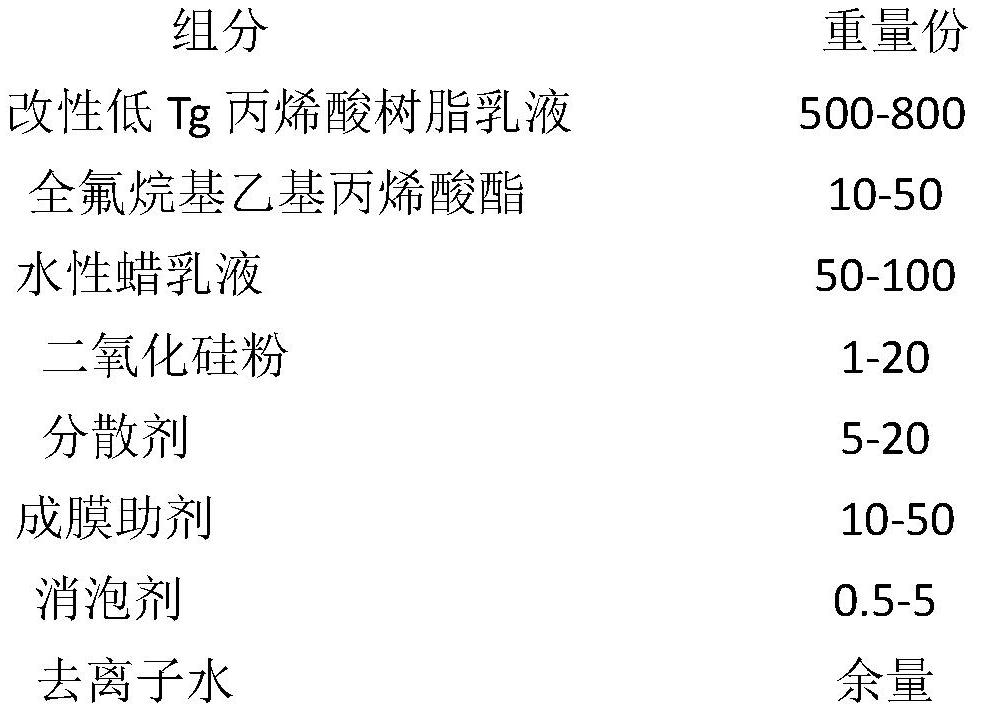

[0023] A highly hydrophobic water-based glazing oil, the water-based glazing oil consists of the following components by weight:

[0024]

[0025] The preparation method of the water-based glazing oil of this embodiment is as follows: take a modified low-Tg acrylic resin emulsion, add perfluoroalkyl ethyl acrylate, water-based wax emulsion, silica powder, dispersant, film-forming assistant to it in sequence Agent, defoamer and deionized water, after each component is added, mechanically stir for 5 minutes, then add the next component, until the addition is complete and stir for 5 minutes, the highly hydrophobic water-based varnish is obtained.

[0026] Evaluation:

[0027] Waterproof performance test:

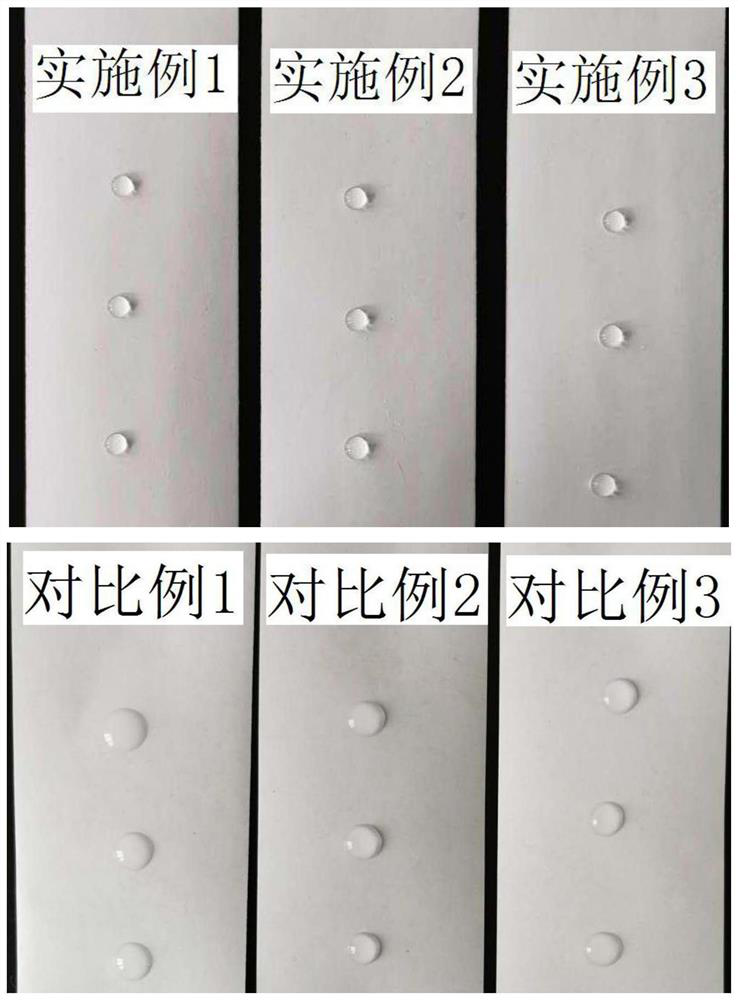

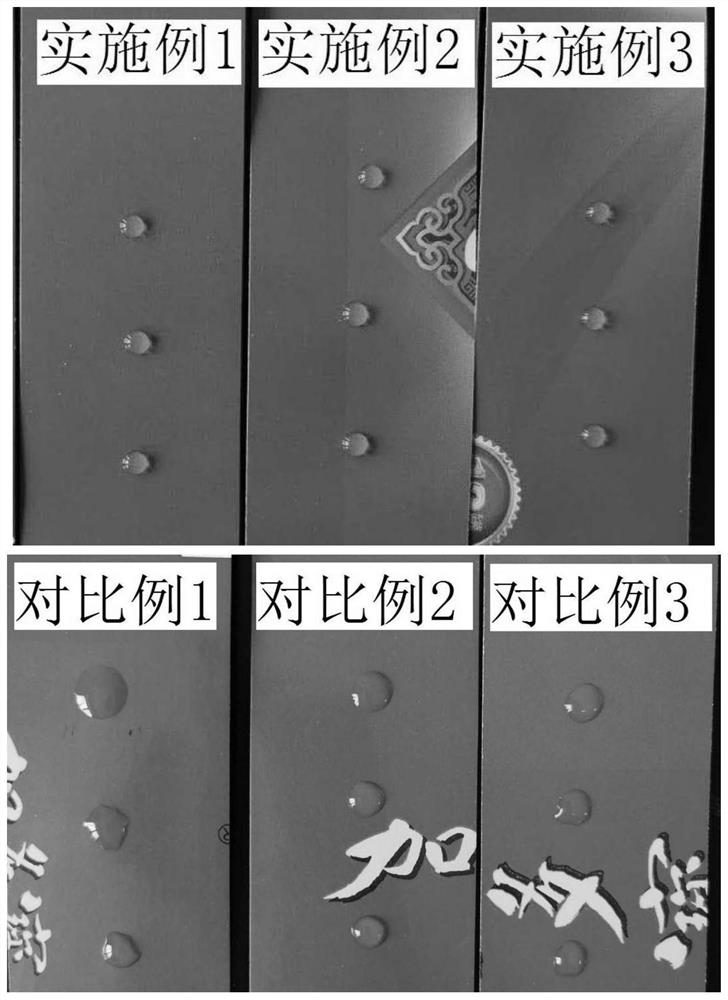

[0028] Coat 170g of coated paper (unprinted), and use a 300-line color wheel to coat and polish at a temperature of 25°C and a humidity of 60%. After standing for 5 minutes, drip water to test its waterproof performance, see the display picture figure 1 .

[0029] Take 1...

Embodiment 2

[0037] A highly hydrophobic water-based glazing oil, the water-based glazing oil consists of the following components by weight:

[0038]

[0039]

[0040] The preparation method of the water-based glazing oil of this embodiment is the same as that of Embodiment 1.

[0041] Correlation performance detection is the same as embodiment 1.

Embodiment 3

[0043] A highly hydrophobic water-based glazing oil, the water-based glazing oil consists of the following components by weight:

[0044]

[0045] The preparation method of the water-based glazing oil of this embodiment is the same as that of Embodiment 1.

[0046] Correlation performance detection is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com