A booster pump variable frequency drive controller

A variable frequency drive and controller technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve problems such as short service life, low energy utilization rate, poor heat dissipation performance of the pump motor, etc., to achieve Ease of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

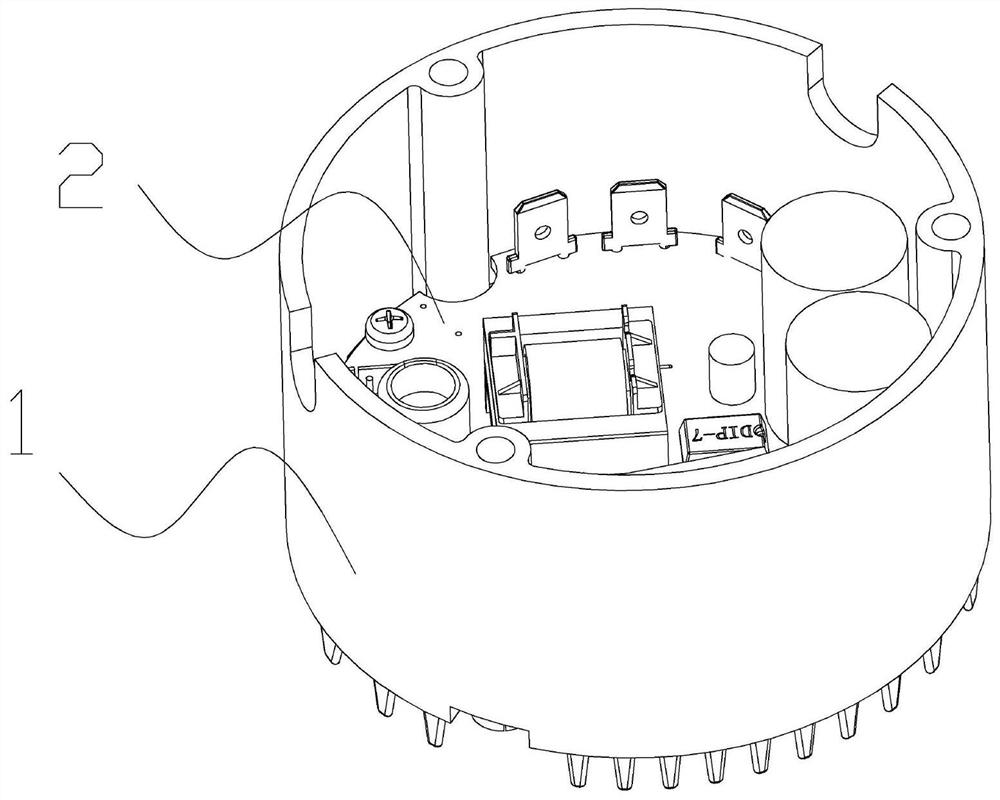

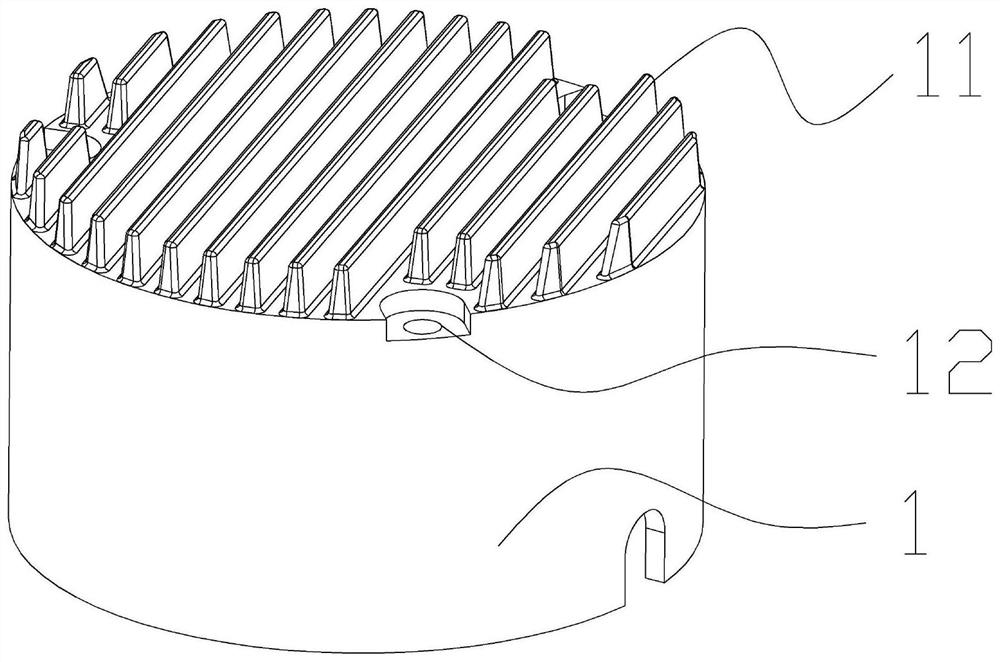

[0045] Such as Figures 1 to 11 As shown, the present invention provides a booster pump variable frequency drive controller, including:

[0046] Shell 1, the shell 1 is cylindrical, and the bottom is fixedly connected with several vertical plates 11 arranged equidistantly;

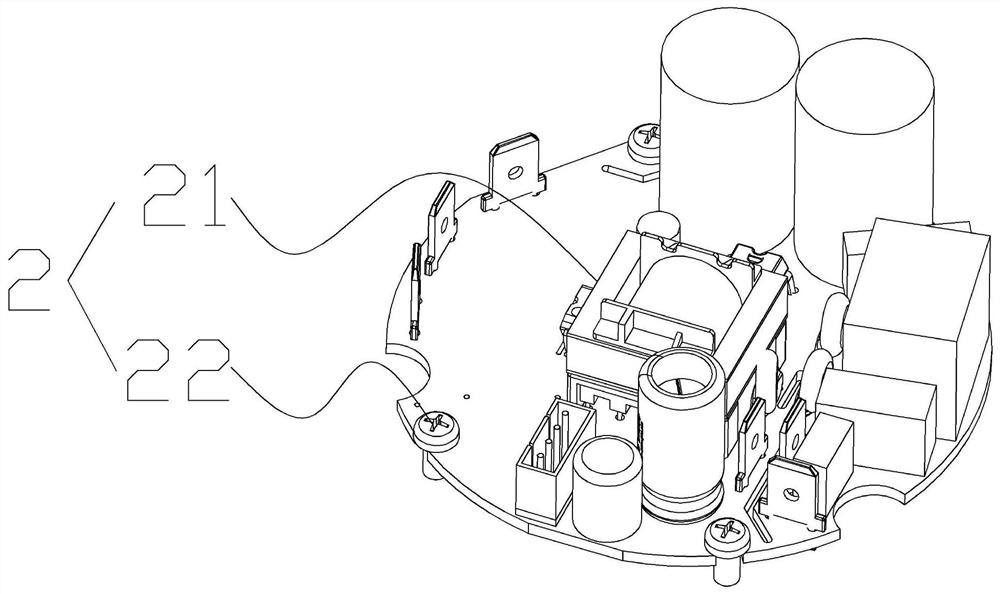

[0047] Control board 2, described control board 2 is provided with control circuit 21 and screw 22, and described control circuit 21 comprises power supply circuit, main control circuit, interface circuit, protection circuit and three-phase full-bridge inverter circuit; The circuit includes a single-chip microcomputer circuit, a temperature sampling circuit, a current sampling circuit and a voltage sampling circuit; The full-bridge circuit is electrically connected to the main control circuit, and the main control circuit is electrically connected to the protection circuit and the three-phase inverter full-bridge circuit respectively; the three-phase full-bridge inverter circuit includes three combined tu...

Embodiment 2

[0053] Such as Figures 1 to 11 As shown, the present invention provides a booster pump variable frequency drive controller, including:

[0054] Shell 1, the shell 1 is cylindrical, and the bottom is fixedly connected with several vertical plates 11 arranged equidistantly;

[0055] Control board 2, described control board 2 is provided with control circuit 21 and screw 22, and described control circuit 21 comprises power supply circuit, main control circuit, interface circuit, protection circuit and three-phase full-bridge inverter circuit; The circuit includes a single-chip microcomputer circuit, a temperature sampling circuit, a current sampling circuit and a voltage sampling circuit; The full-bridge circuit is electrically connected to the main control circuit, and the main control circuit is electrically connected to the protection circuit and the three-phase inverter full-bridge circuit respectively; the three-phase full-bridge inverter circuit includes three combined tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com