Online detection and automatic replenishment system for phosphorization tank liquid

A supply system and phosphating tank technology, applied in the field of phosphating treatment devices, can solve problems such as low accuracy, large error in test results, and cumbersome process, so as to improve accuracy, improve detection accuracy, and reduce interference factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

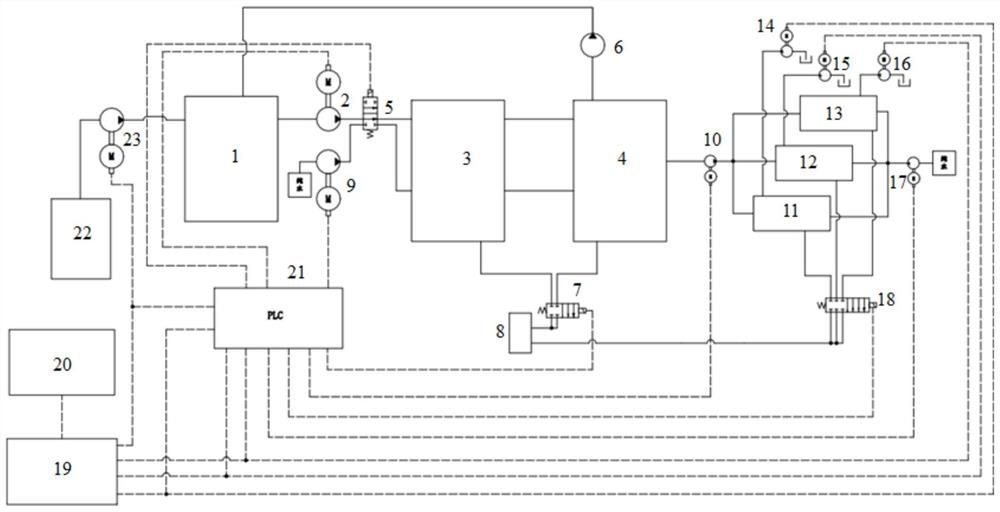

[0035] refer to figure 1 , a kind of phosphating tank 1 fluid online detection and automatic replenishment system of the present embodiment, comprising:

[0036] The sampling pretreatment device includes a filter barrel 3, an isolation tank 4 and a backwash unit. The filter barrel 3 communicates with one or more phosphating tanks 1 and filters the liquid in the phosphating tank 1 to remove the phosphorus after the phosphating slag. The phosphating tank 1 liquid is pumped into the isolation tank 4 for cooling, and the isolation tank 4 is respectively communicated with the detection mechanism and the phosphating tank 1 through pipelines, and the backwash unit includes a pretreatment cleaning pump 9 electrically connected with a PLC controller 21 and The pipelines of the cleaning water source, the filter bucket 3, the isolation tank 4, and the waste liquid recovery device 8 are connected successively; the first solenoid valve 5 is arranged on the pipeline connected to the phospha...

Embodiment 2

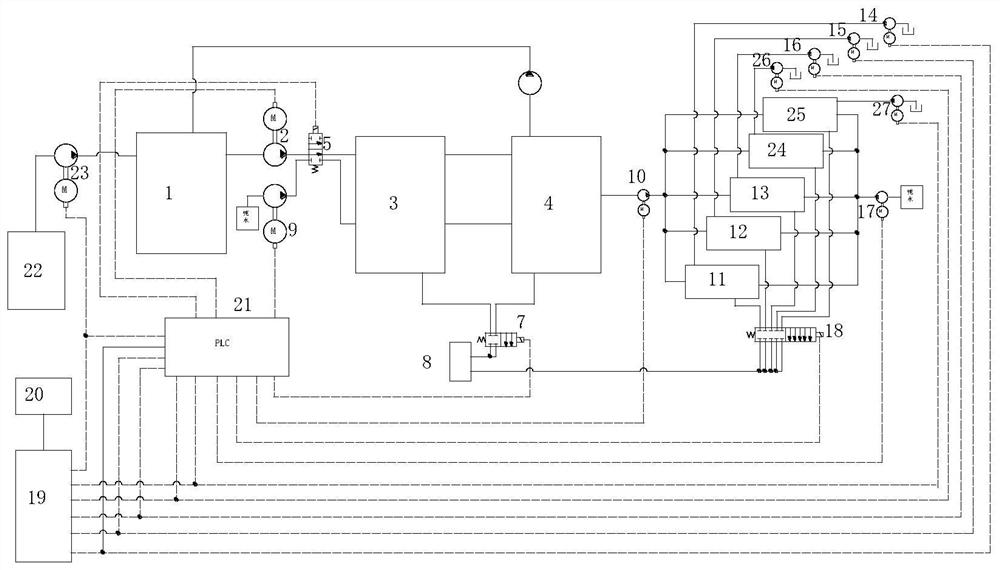

[0055] refer to figure 2 , a kind of phosphating tank 1 liquid on-line detection and automatic replenishment system of the present embodiment, compare with embodiment 1, there is following difference:

[0056] The quantity of described titration device is 5, comprises total acid / free acid titration device 11, acid radical ion titration device 12, Fe 2+ Titration device 13, Zn 2+ / Ni 2+ Titration device 24 and Mn 2+ Titration device 25, described total acid / free acid titration device 11 is used for measuring total acid, free acid in the phosphating solution, acid radical ion titration device 12, Fe 2+ Titration device 13, Zn 2+ / Ni 2+ Titration device 24 and Mn 2+ Titration device 25 is respectively used for measuring the Cl in the phosphating solution - and SO 4 2- , Fe2+ , Zn 2+ and Ni 2+ , Mn 2+ concentration.

[0057] Wherein, the indicator electrode includes a pH electrode, an Ag electrode, a platinum electrode, a Hg / Hg-EDTA electrode, etc., and the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com