Phenol cracking parameter automatic optimization method and device based on artificial intelligence

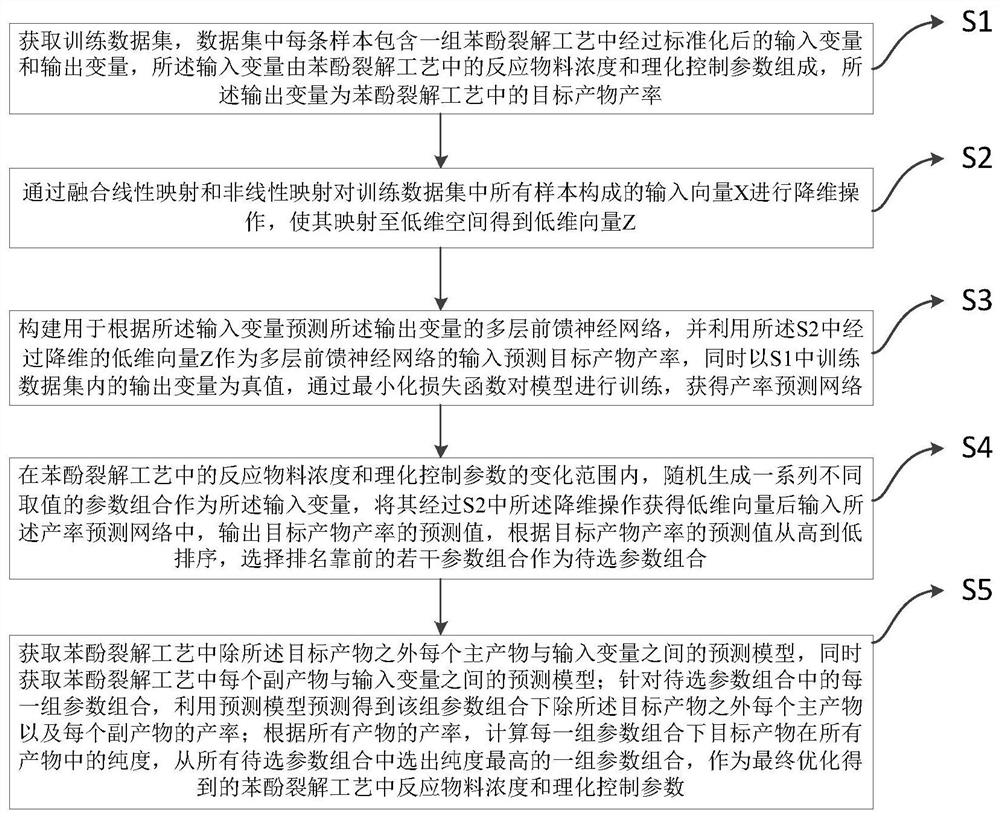

An automatic optimization and artificial intelligence technology, applied in the field of neural network models, can solve the problems of rare optimization of phenol cracking process, difficult to predict control, etc., and achieve stable yield, controllable parameters, and improved yield and purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

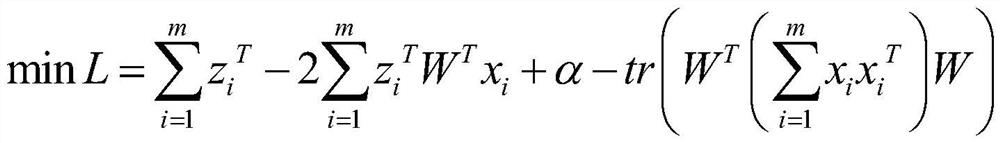

Method used

Image

Examples

Embodiment

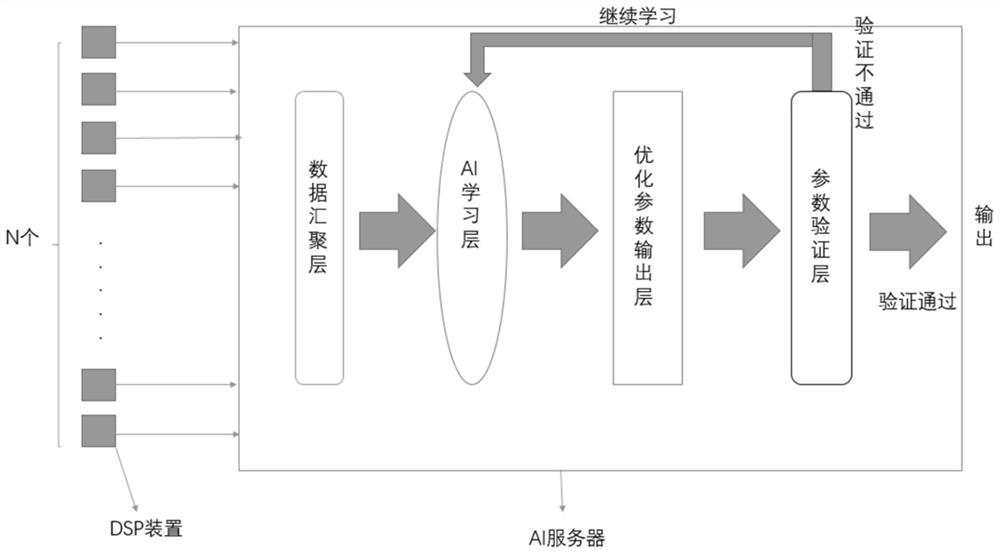

[0072] The phenol cracking process in the present embodiment is the cumene method. like figure 2As shown, in the reactor of this process, multiple DSPs are deployed at the gate of the parameter control equipment for data collection. Then the data is sent to the AI server, and the parameters are optimized by the AI server. The data aggregation layer, AI learning layer, optimization parameter output layer and parameter verification layer are set in the AI server. The data aggregation layer is used to process the input data, the AI learning layer is used for the construction and training of the neural network, the parameter optimization output layer is used for purity optimization, and the parameter verification layer is used for manual verification of parameters. DSP output, and finally adjust the process parameters. The artificial intelligence-based automatic optimization method of phenol cracking parameters adopted by the server is specifically as described in S1-S5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com