MicroLED display device based on quantum dot color conversion layer and preparation method of MicroLED display device

A technology for color conversion layers and display devices, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of waste of quantum dots, reduce conversion efficiency, and limit equipment accuracy, and achieve the effect of fewer steps and suppressing stray light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

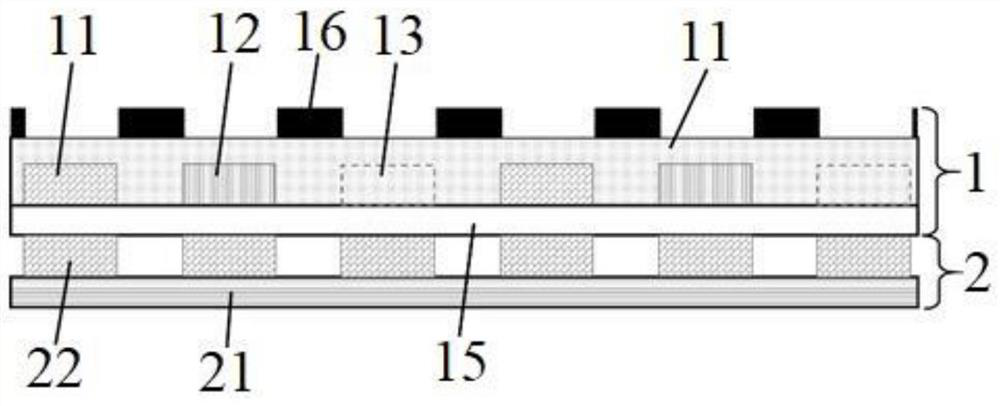

[0049] figure 1 The structure of the Micro LED display device based on the quantum dot color conversion layer according to Embodiment 1 of the present invention is shown.

[0050] Such as figure 1 As shown, the MicroLED display device based on the quantum dot color conversion layer includes a quantum dot color conversion layer 1 and a MicroLED array 2, and the MicroLED array 2 includes a driving substrate 21 and a plurality of LED chips 22, and a plurality of LED chips 22 are prepared on the driving substrate 21 , the driving substrate 21 is used to supply power to a plurality of LED chips 22 , and the plurality of LED chips 22 emit light under the power supply of the driving substrate 21 .

[0051] The quantum dot color conversion layer 1 is aligned and bonded to the MicroLED array 2, so that the light emitted by multiple LED chips 22 is converted into light of different colors through the quantum dot color conversion layer 1, thereby realizing a full-color MicroLED display ...

Embodiment 2

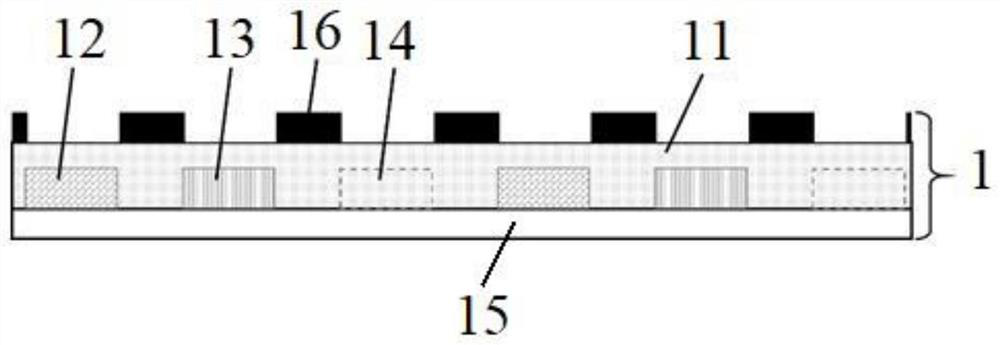

[0076] Figure 5 The structure of the Micro LED display device based on the quantum dot color conversion layer according to the second embodiment of the present invention is shown.

[0077] Such as Figure 5 As shown, the MicroLED display device 1 based on the quantum dot color conversion layer according to the second embodiment of the present invention includes a quantum dot color conversion layer 1 and a MicroLED array 2, and the MicroLED array 2 includes a driving substrate 21 and a plurality of LED chips 22, and the quantum dot The color conversion layer 1 is aligned and bonded to the MicroLED array 2, so that the light emitted by multiple LED chips 22 is converted into light of different colors through the quantum dot color conversion layer 1, thereby realizing a full-color MicroLED display device.

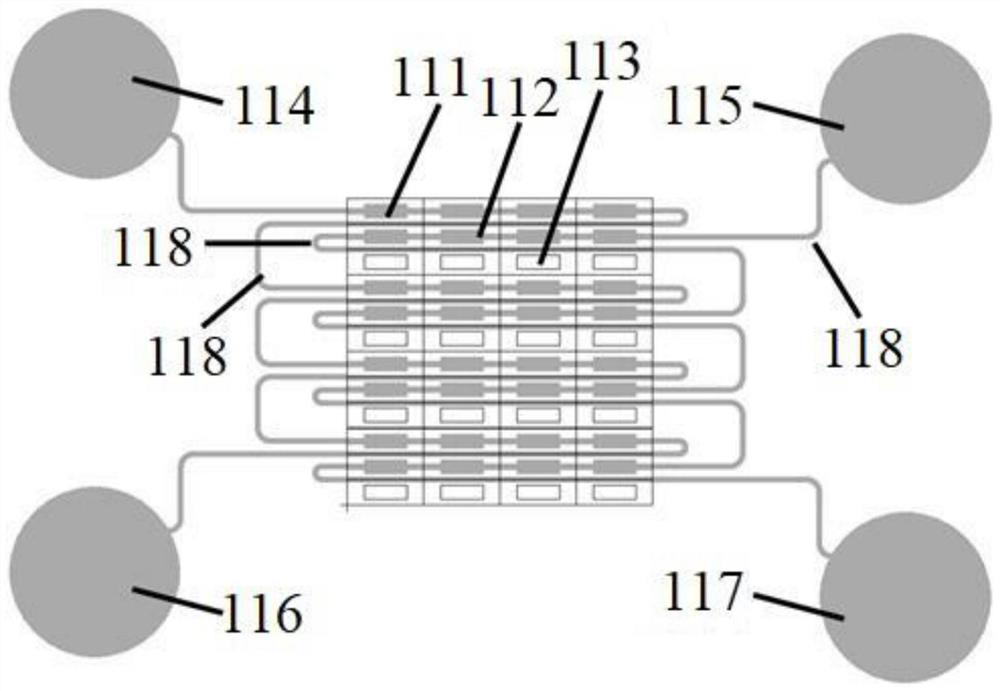

[0078] Image 6 It is the structure of the quantum dot color conversion layer according to the second embodiment of the present invention.

[0079] Such as Image 6 As sh...

Embodiment 3

[0083] Figure 7 The flow chart of the method for manufacturing the Micro LED display device based on the quantum dot color conversion layer according to the third embodiment of the present invention is shown.

[0084] Such as Figure 7 As shown, the preparation method of the Micro LED display device based on the quantum dot color conversion layer provided by the third embodiment of the present invention includes the following steps:

[0085] S1. Prepare the Micro LED display array and the quantum dot color conversion layer respectively, and align and bond the prepared Micro LED display array and the quantum dot color conversion layer to form a Micro LED display device.

[0086] Figure 8 The dynamic process of the preparation method of the quantum dot-based color conversion layer according to the third embodiment of the present invention is shown.

[0087] Such as Figure 7 and Figure 8 Commonly shown, the preparation method based on the quantum dot color conversion lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com