Design method of deicing and melting transformer with wide voltage regulation and fine current adjustment

A transformer and wide voltage regulation technology, applied in the design field of ice-melting transformers, can solve the problems of lack of adaptability to line parameter changes, difficult to achieve optimal design results, and too many transformer gears, and achieve excellent design results, The effect of a small number of stalls and a simple design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

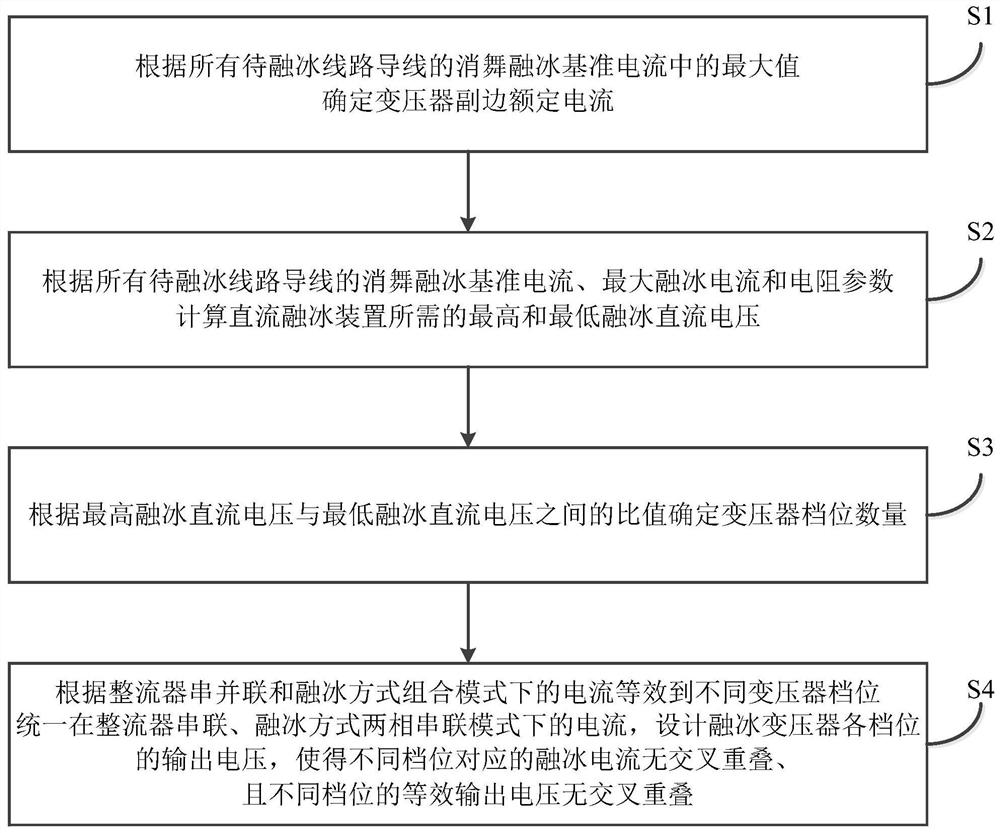

[0021] This example discloses a blending transformer design method for banging the wide regulation range and can also have a fine-tunable ice current, such as figure 1 As shown, including the following steps:

[0022] Step S1 determines the secondary rated current of the transformer according to the maximum value of all the long-defraulous ice based on the ice line to be melted.

[0023] Step S2, calculate the highest and lowest end of the ice devices required for the Direct Rongshing Device according to all the long-term bursting ice based on the ice-free line of the ice line wire to be brought to the ice line wire.

[0024] Step S3 determines the number of transformer gear positions based on the ratio between the highest threshing DC voltage and the lowest threshing DC voltage.

[0025] Step S4, depending on the current of the rectifier string and the fluid fluid in combination mode to different transformer gear positions in the rectifier series, the flow of the ice pattern, the...

Embodiment 2

[0072] In accordance with Example 1, the present embodiment combines a specific design case to further explain the present invention.

[0073] 1.1) Summarize all the wire type and resistance parameters of each line and resistance parameters for each line and resistance parameters of each line. For a fixed DC mesh, the line type and parameters of all the ice-free lines of the substation are shown in Table 2.

[0074] Table 2

[0075] Line number Voltage (kV) Wire model Length (km) Resistance R l (Ω)

Insulating l (Ω)

1# 220 LGJ-300 / 40 10.6 1.00 4.35 2# 220 Jlha1-400 51 3.67 20.45 3# 220 LGJ-400 / 35 56.053 4.04 22.48 4# 110 LGJ-300 / 40 12.18 1.14 4.99 5# 110 LGJ-240 / 30 9.375 1.23 3.76 6# 110 LGJ-240 / 30 44.515 5.83 17.85 7# 110 LGJ-240 / 30 3.5 0.46 1.40 8# 110 LGJ-240 / 30 16.684 2.19 6.69 9# 110 LGJ-240 / 30 22.757 2.98 9.13 10# 110 LGJ-240 / 30 8.573 1.12 3.44 11# 110 LGJ-240 / 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com