Preparation method of cosmetic emulsifying thickener

A technology for emulsifying thickeners and cosmetics, applied in chemical instruments and methods, mixing methods, chemical/physical processes, etc., can solve the problems of difficulty in maintaining effective cooling time of cooling water, influence of thickener purity, poor mixing degree, etc. To achieve the effect of improving the emulsification effect, improving the degree of fineness, and improving the degree of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

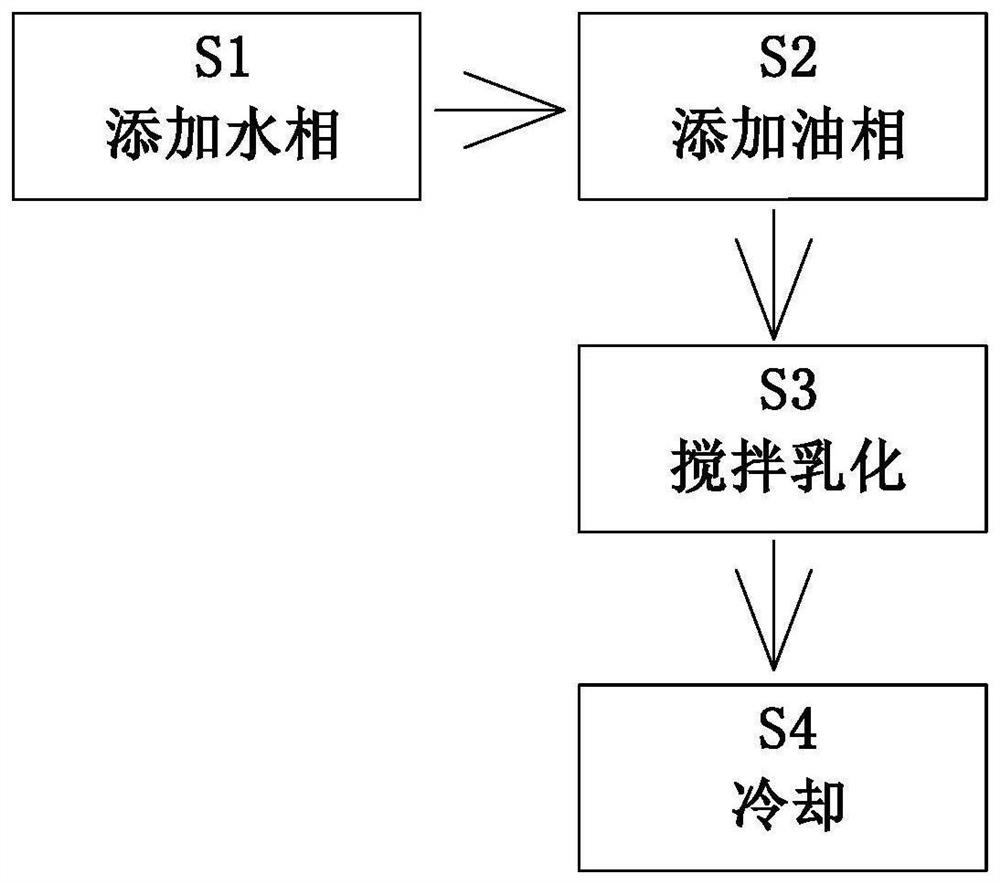

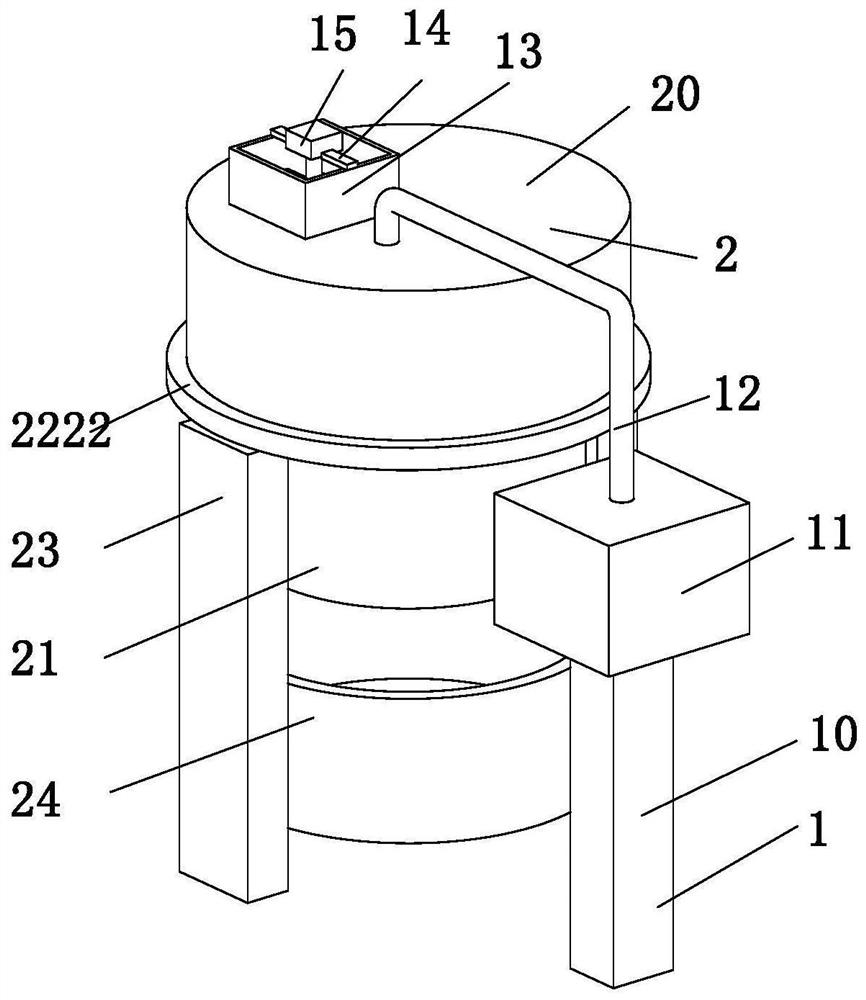

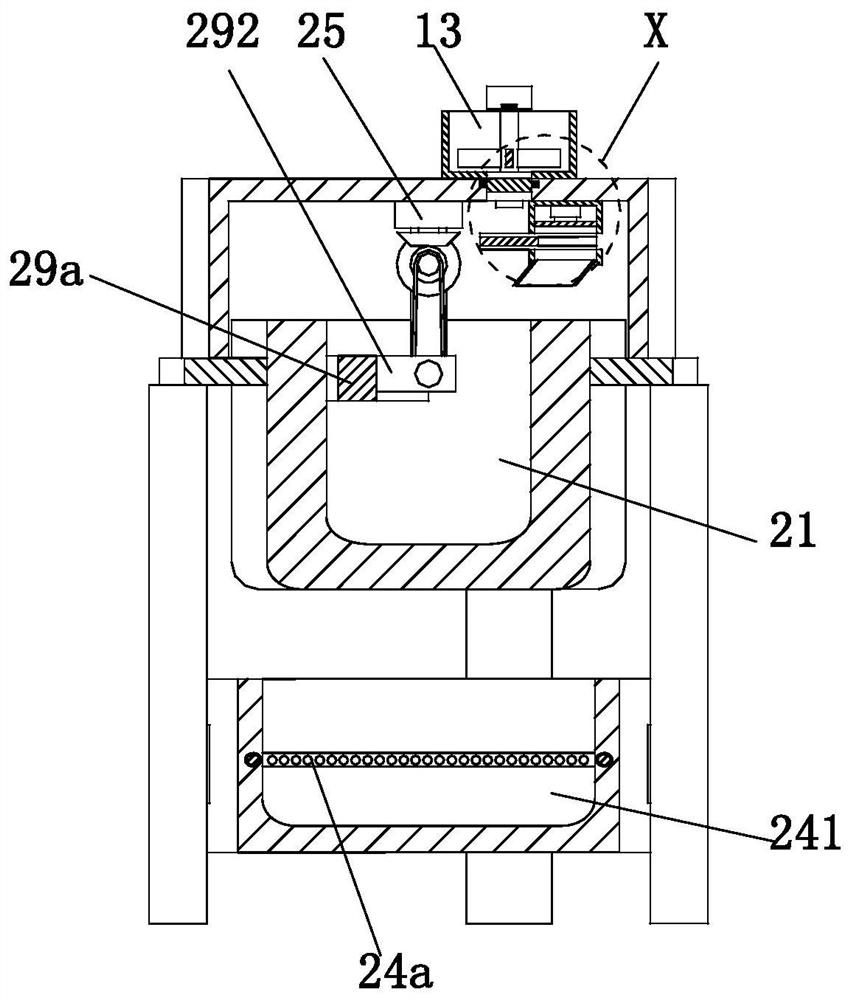

[0040] like Figure 1 to Figure 10 A preparation method of a cosmetic emulsification thickener is shown, which uses a cosmetic emulsification thickener preparation device, the cosmetic emulsification thickener preparation device includes a feeding mechanism 1 and a stirring mechanism 2, and is carried out by a cosmetic emulsification thickener preparation device The specific preparation method during the preparation of cosmetic emulsifying thickener is as follows:

[0041] S1. Adding the water phase: the water phase is transported into the feed pipe 12 through the reservoir 11, and finally enters the stirring mechanism 2;

[0042] S2. Adding oil phase: Pour the oil phase into the discharge basket 13 manually, and at the same time drive the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com