Polylactic resin production equipment capable of improving tensile strength

A polylactic acid resin and production equipment technology, which is applied in the field of polylactic acid resin production equipment with increased tensile strength, can solve the problems of short stirring time, affecting the tensile strength of polylactic acid resin, insufficient fusion of chemical substances and polylactic acid resin, etc. problem, to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

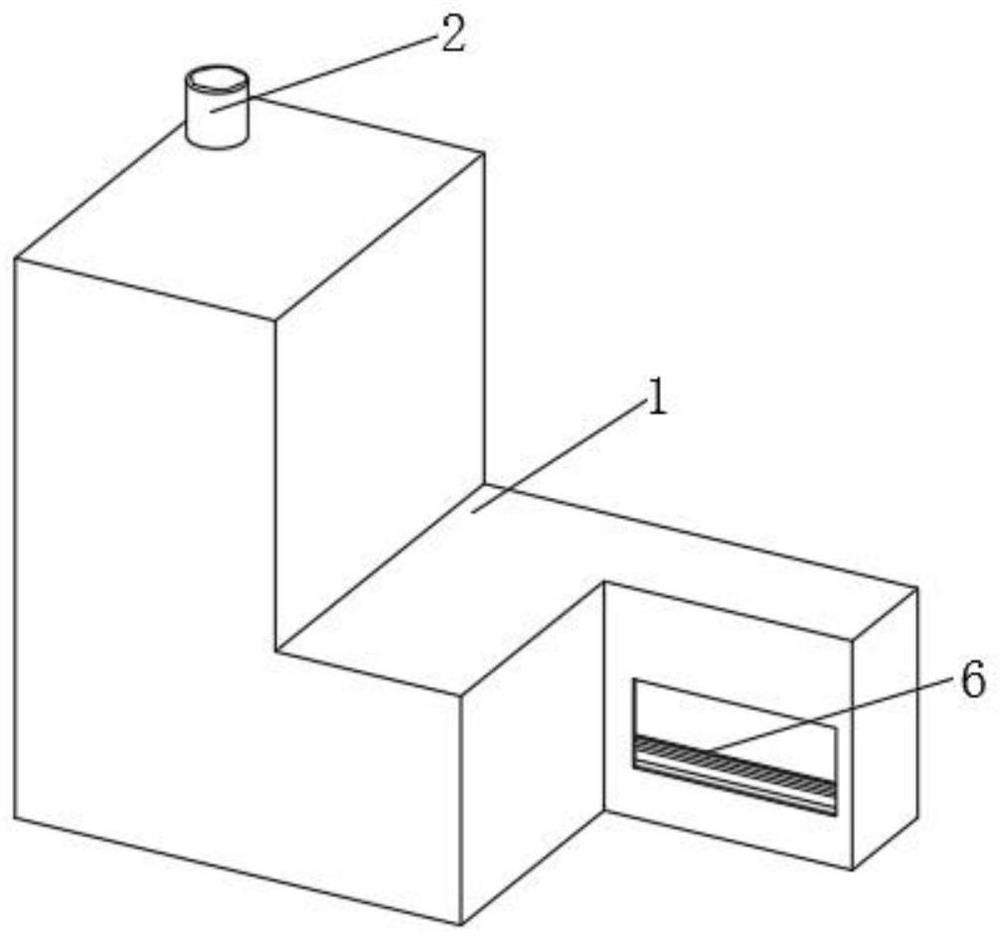

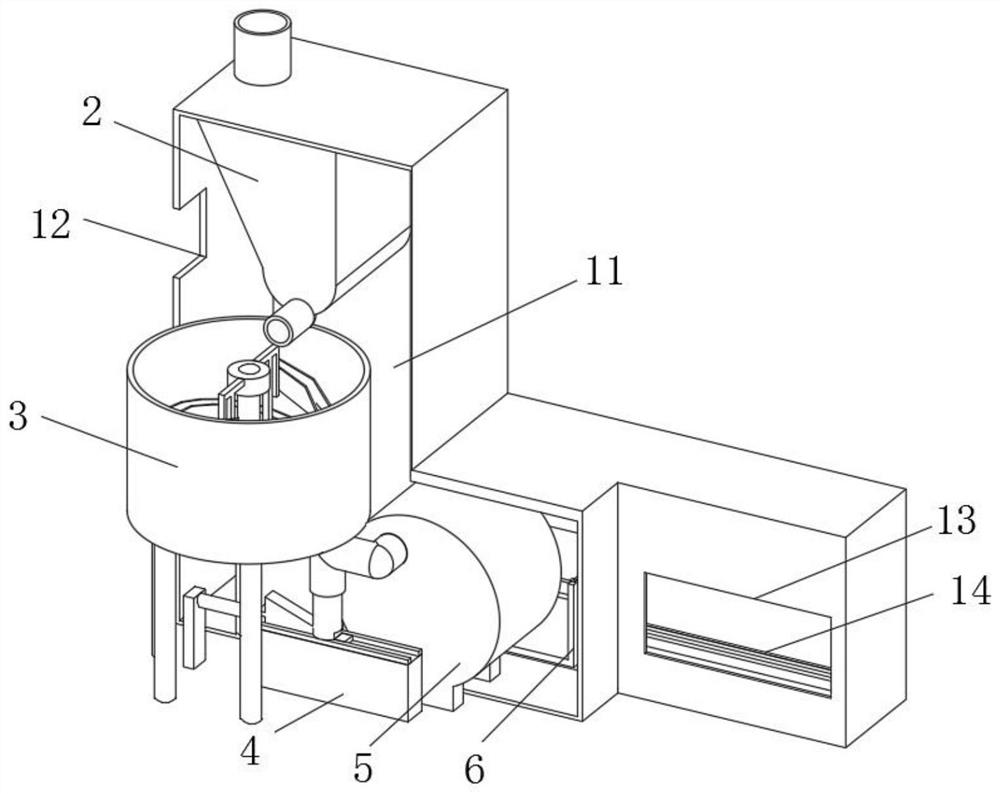

[0052] see Figure 1-Figure 12 As shown, a polylactic acid resin production equipment with increased tensile strength is provided, including a device shell 1, characterized in that: the inside of the device shell 1 at least includes a heating and melting device 2, a stirring device 3, a blocking device 4, and a kneading device 5 and sliding device 6;

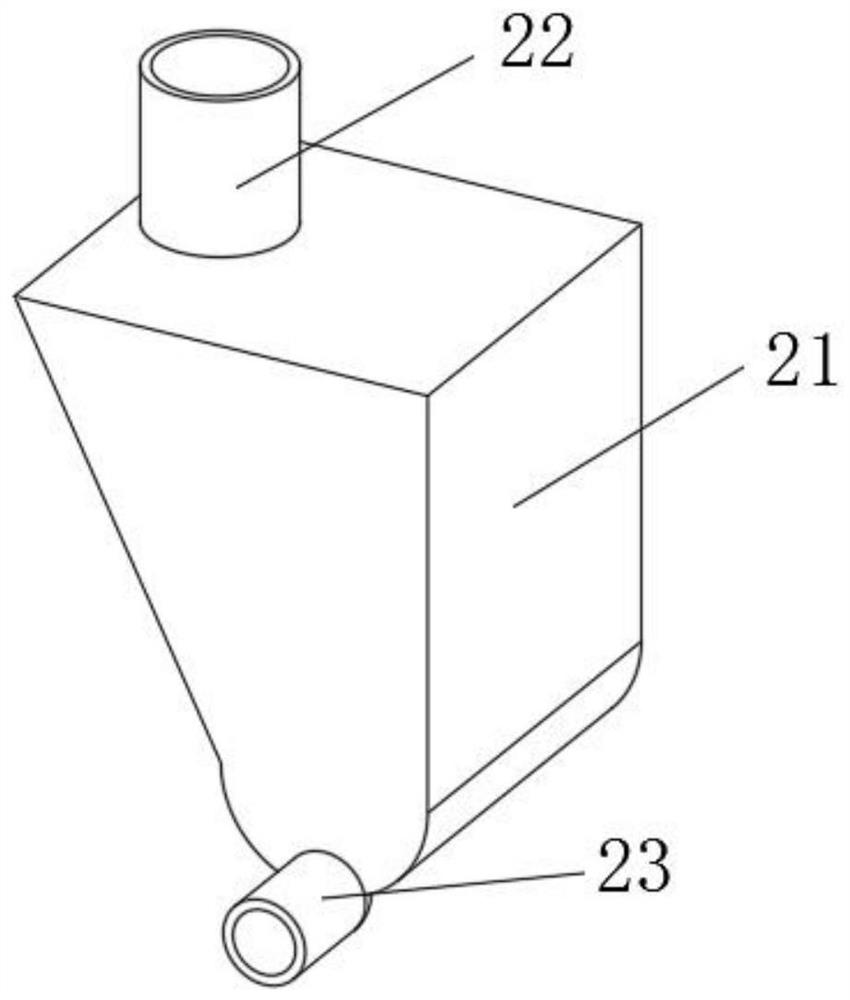

[0053] The heating and melting device 2 includes a heating shell 21, the top of the heating shell 21 is fixedly connected with a feeding pipe 22, the bottom side of the heating shell 21 is fixedly connected with a discharge pipe 23, and the inside of the discharge pipe 23 is fixedly connected with an inclined baffle 27 and Heating plate 26, the bottom of heating plate 26 is fixedly connected with electric heating wire 29;

[0054] When the heating and melting device 2 of this embodiment is in use, the electric heating wire 29 is energized so that the electric heating wire 29 generates heat, the heating plate 26 is heated, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com