Improving method of salt-fog tests on broken section of iron pieces

A technology of salt spray test and iron parts, which is applied in the direction of liquid chemical plating, superimposed layer plating, coating, etc., can solve the problems of corrosion and reduce the salt spray test performance of iron products, so as to simplify the process and improve Salt spray test performance, effect of improving nickel plating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0024] A salt spray test lifting method for a section of an iron piece comprises the following steps:

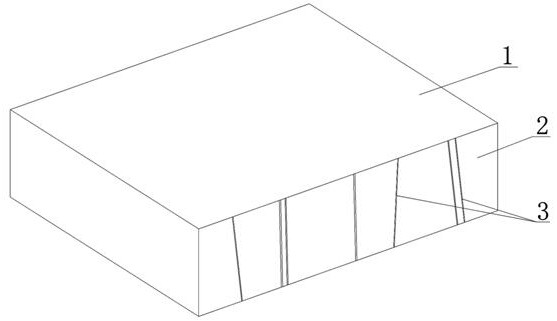

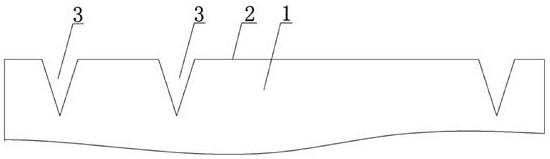

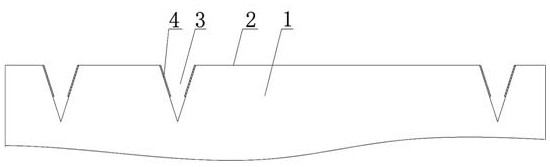

[0025] S1, the grinding process of the iron piece: the broken section 2 of the iron piece 1 is rolled by rolling to reduce the height of the groove 3 on the broken section 2;

[0026] S2, the degreasing process of the iron piece: the iron piece 1 is immersed in the lye, and the ultrasonic wave is passed into the lye, and under the joint action of the lye and the ultrasonic wave, the oil stain attached to the surface of the iron piece 1 is removed. After degreasing for a period of time, the degreasing of iron parts can be realized;

[0027] S3, taking out the degreased iron piece 1 from the alkali washing tank, and washing away the lye on the surface of the iron piece 1 with clear water;

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com