A kind of multi-C-shaped high hollow density bright fiber and preparation method thereof

A fiber and high-tech technology, applied in the field of multi-C-shaped high-hollow bright fiber and its preparation, can solve the problems of stuffy clothes, heavy fabrics, poor moisture absorption and air permeability, etc., achieve bright luster, increase light weight, and improve moisture absorption and air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

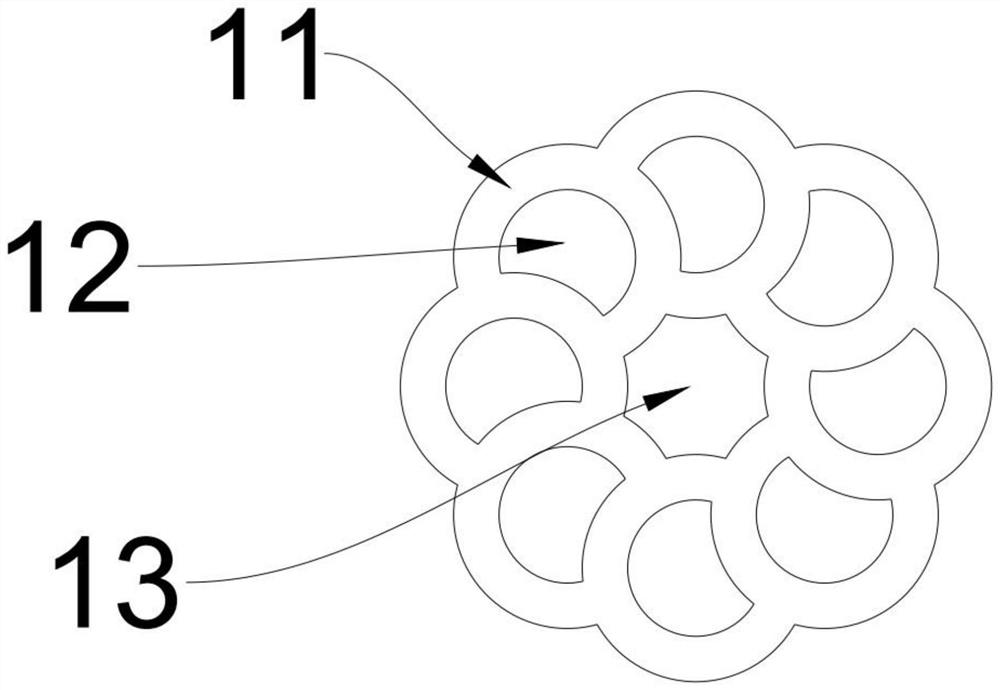

[0033] like figure 2 , 4 As shown in and 6, a multi-C-shaped high-cavity bright fiber, the fiber comprises a plurality of filaments 11 distributed around the center of the fiber with equal diameters, and every two filaments 11 are joined to each other, and Two of the fiber filaments 11 are provided with a first cavity 12 ; the center of the fiber 1 is also provided with a second cavity 13 formed by a plurality of the fiber filaments 11 distributed in a circular shape with equal diameters; the fibers The cross section of the wire 11 is C-shaped; the outer contour of the fiber is formed by a plurality of arcs connected end to end.

[0034] The present invention adopts the multi-C-shaped melt extrusion slits through the fiber filaments 11, and is distributed in an equal diameter ring around the center of the fiber, forming a unique multi-cavity shaped special-shaped cross-sectional structure, and the hollowness can be as high as 40-50% , the fabric has a better lightening effe...

Embodiment 2

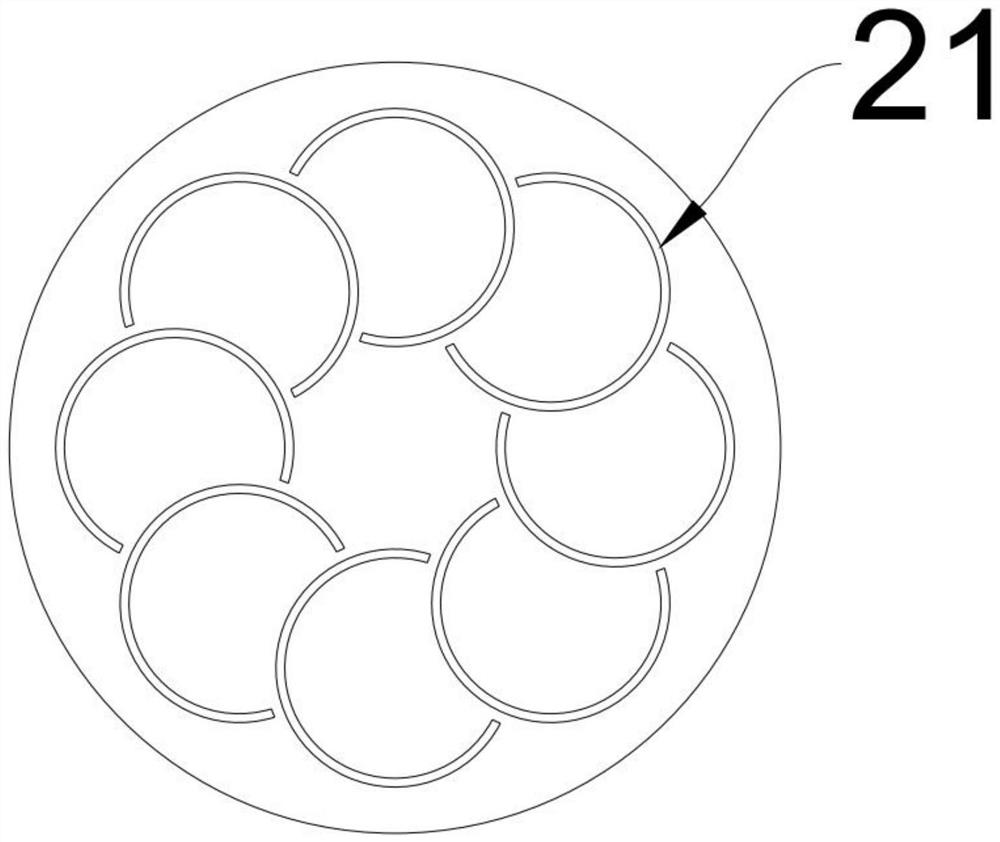

[0043] like figure 1 As shown, a multi-C-shaped high-cavity bright fiber, the fiber includes a plurality of fiber filaments distributed around the center of the fiber with an equal diameter and an annular shape, every two of the fiber filaments are mutually joined, and two of the fiber filaments are The fiber filaments are all provided with a first cavity; the center of the fiber is also provided with a second cavity formed by a plurality of the fiber filaments distributed in a circular shape with equal diameters; the cross-section of the fiber filaments is C-shaped; The outer contour of the fiber is formed by a plurality of arcs connected end to end.

[0044] The present invention also provides a method for preparing the multi-C-shaped high-cavity bright fiber,

[0045] The preparation method of the described multi-C-shaped high-cavity bright light fiber is as follows:

[0046] On the existing FDY spinning machine, polyester is used as the raw material, and the spinneret of...

Embodiment 3

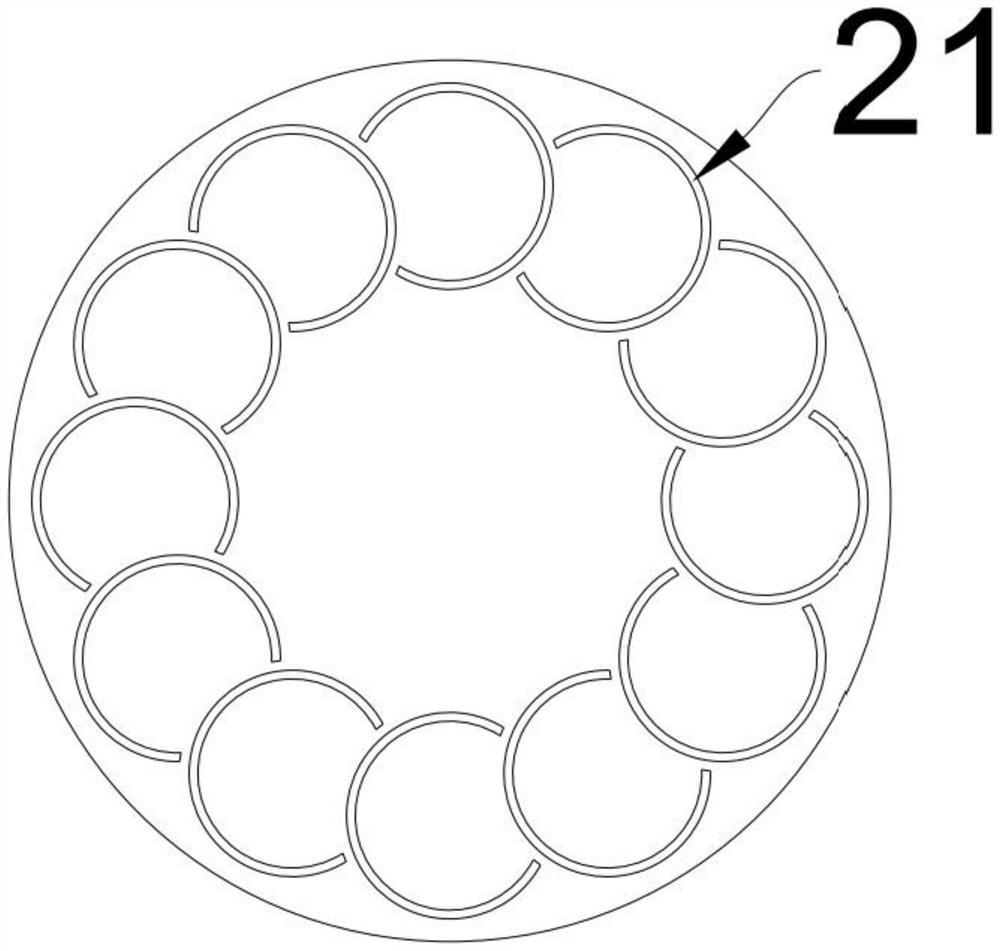

[0058] like image 3 As shown, a multi-C-shaped high-cavity bright fiber, the fiber includes a plurality of fiber filaments distributed around the center of the fiber with an equal diameter and an annular shape, every two of the fiber filaments are mutually joined, and two of the fiber filaments are The fiber filaments are all provided with a first cavity; the center of the fiber is also provided with a second cavity formed by a plurality of the fiber filaments distributed in a circular shape with equal diameters; the cross-section of the fiber filaments is C-shaped; The outer contour of the fiber is formed by a plurality of arcs connected end to end.

[0059] The present invention also provides a method for preparing the multi-C-shaped high-cavity bright fiber,

[0060] The preparation method of the described multi-C-shaped high-cavity bright light fiber is as follows:

[0061] On the existing FDY spinning machine, polyester is used as the raw material, and the spinneret of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com