A kind of melt-blown nonwoven material manufacturing method

A technology of non-woven materials and manufacturing methods, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc. It can solve the problems of affecting the forming effect of melt-blown cloth, reducing fiber continuity, and poor stirring effect, etc., and achieves good results. Molding and electret effect, ensuring continuity, and improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

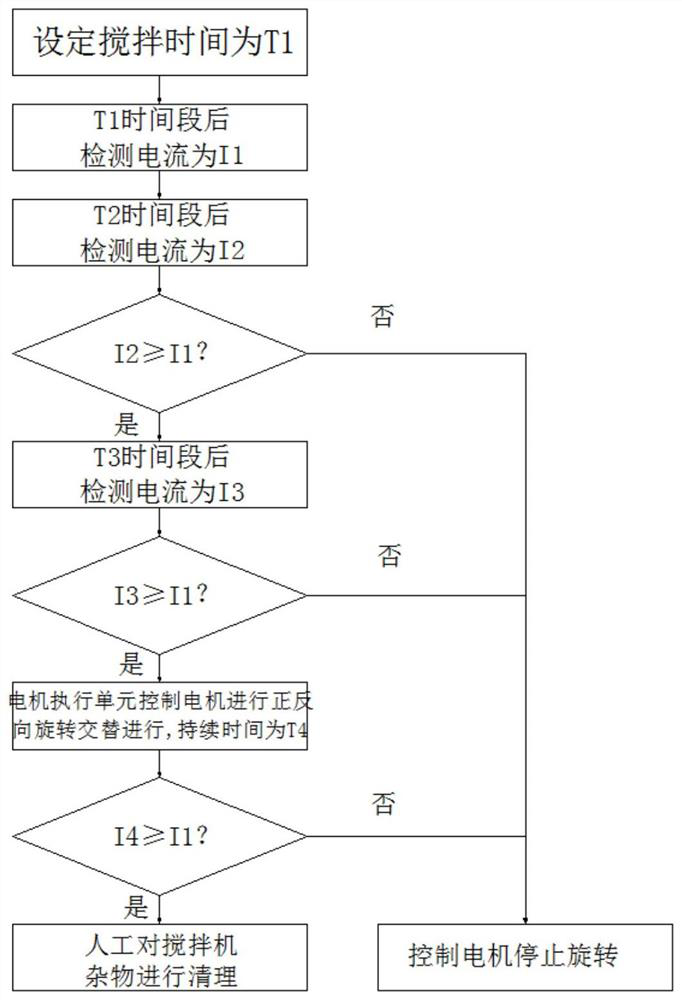

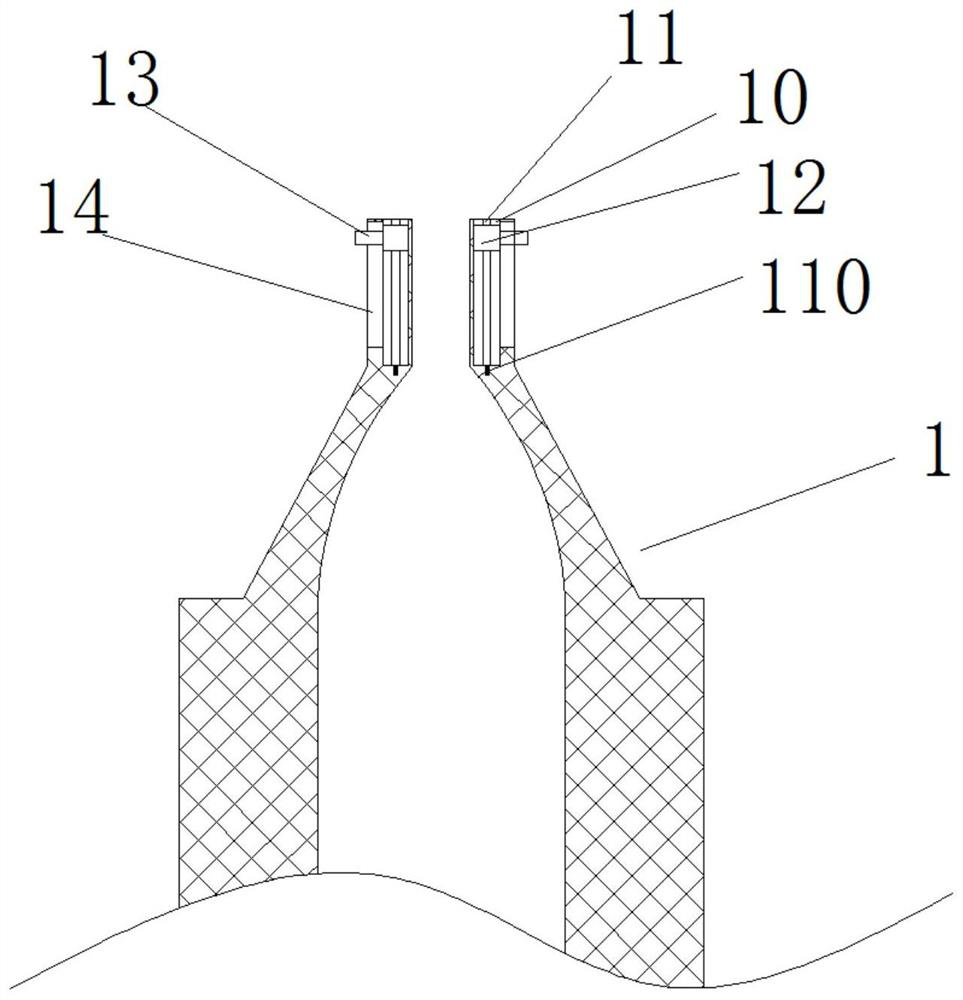

[0029] refer to Figure 1 to Figure 2 An embodiment of a method for manufacturing a melt-blown nonwoven material of the present invention will be further described.

[0030] For ease of description, spatial relative terms such as "upper", "lower", "left", "right", etc. are used in the embodiments to describe the position of one element or feature shown in the figures relative to another element or feature. relation. It will be understood that the spatial terms are intended to encompass different orientations of the device in use or operation in addition to the orientation depicted in the figures. For example, if the device in the figures is turned over, elements described as "below" other elements or features would then be oriented "above" the other elements or features. Thus, the exemplary term "lower" can encompass both an orientation of above and below. The device may be otherwise oriented (rotated 90 degrees or at other orientations) and the spatially relative specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com