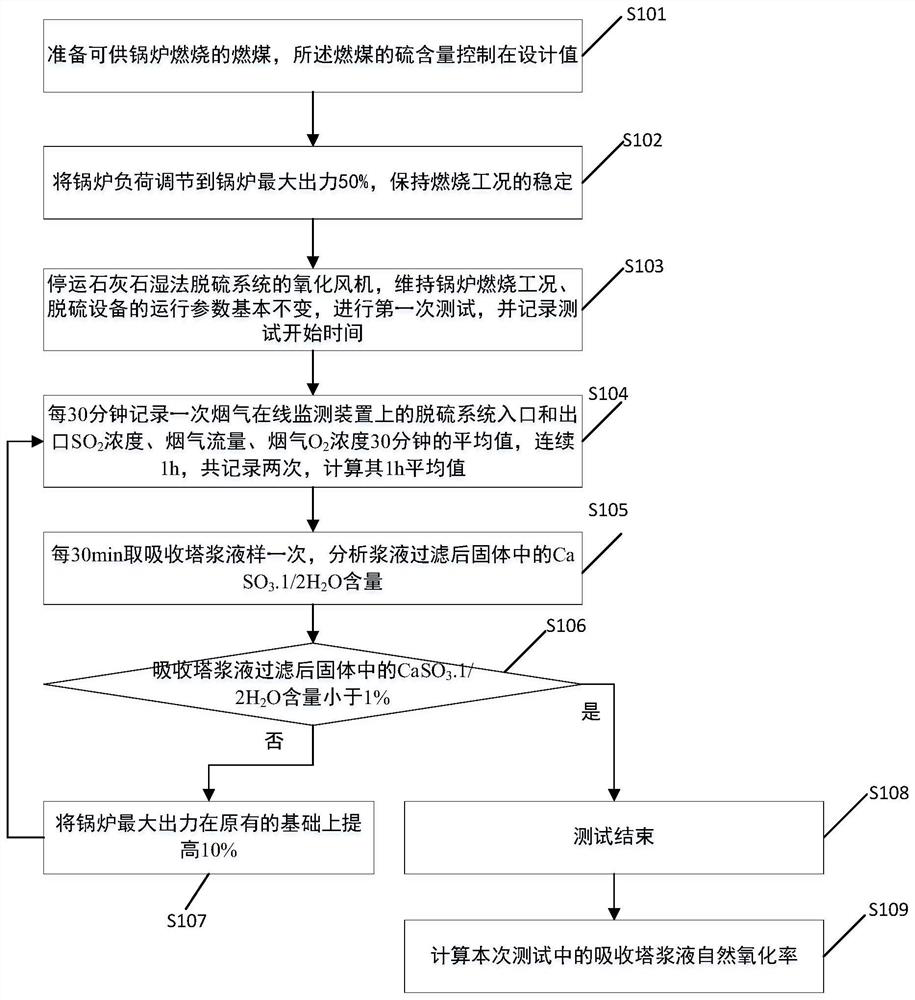

Method for testing natural oxidation rate of limestone wet desulphurization absorption tower slurry

A wet desulfurization and natural oxidation technology, applied in chemical method analysis, chemical instruments and methods, and detection of element existence through oxidation, etc., can solve problems such as equipment waste, increased power consumption of desulfurization system, and failure of desulfurization system to operate normally. , to achieve the effect of simple test method and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

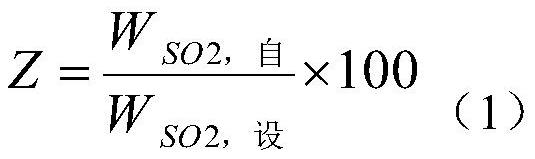

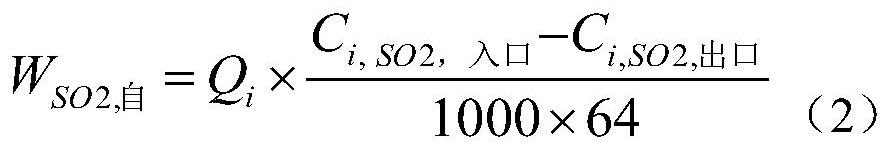

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Natural oxidation rate test of limestone wet flue gas desulfurization system of No. 2 unit of 330MW unit in a certain power plant

[0061] 1. The 330MW unit of a power plant in Guangxi adopts a limestone wet flue gas desulfurization system. The absorption tower has 4 spray layers (corresponding to 4 slurry circulation pumps). The design value of sulfur content in coal combustion is 2.83%. 2 Concentration FGD inlet design value is 6800mg / m 3 (mark, dry, O 2 6%), the designed flue gas volume is 1089235m 3 / h (mark, dry, O 2 6%), which emits SO 2 Concentration allowable discharge standard is less than 400mg / m 3 (mark, dry, O 2 6%). The forced oxidation air system set up is one tower with two oxidation fans (one for use and one for standby), and the flow rate of one oxidation fan is 19000m 3 / h (standard state).

[0062] 2. The designed coal sulfur content of the boiler is Sar=2.83%, and the coal burning volume is 160t / h when the boiler is fully loaded. F...

Embodiment 2

[0076] Example 2 Natural oxidation rate test of limestone wet flue gas desulfurization system of No. 1 unit of 2×300MW units in a certain power plant

[0077] 1. The 300MW unit of a power plant in Guangxi adopts a limestone wet flue gas desulfurization system. The absorption tower adopts a liquid column absorption tower (3 slurry circulation pumps). The design value of sulfur content in coal combustion is 1.0%. 2 Concentration FGD inlet design value is 2089mg / m 3 (mark, dry, O 2 6%), the designed flue gas volume is 1,055,494m 3 / h (mark, dry, O 2 6%), which emits SO 2 Concentration allowable discharge standard is less than 100mg / m 3 (mark, dry, O 26%). The forced oxidation air system set up is one tower with two oxidation fans (one for use and one for standby), and the flow rate of one oxidation fan is 3800m 3 / h (standard state).

[0078] 2. The designed coal sulfur content of the boiler is Sar=1.0%, and the coal burning volume is 160t / h when the boiler is fully loade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com