Method for testing forced oxidation air utilization rate of limestone wet desulphurization

A technology of wet desulfurization and forced oxidation, applied in chemical instruments and methods, separation methods, measuring devices, etc., can solve problems such as waste of equipment, increased power consumption of the desulfurization system, incomplete oxidation of the slurry in the absorption tower, etc. The method is simple, the normal operation is guaranteed, and the result is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

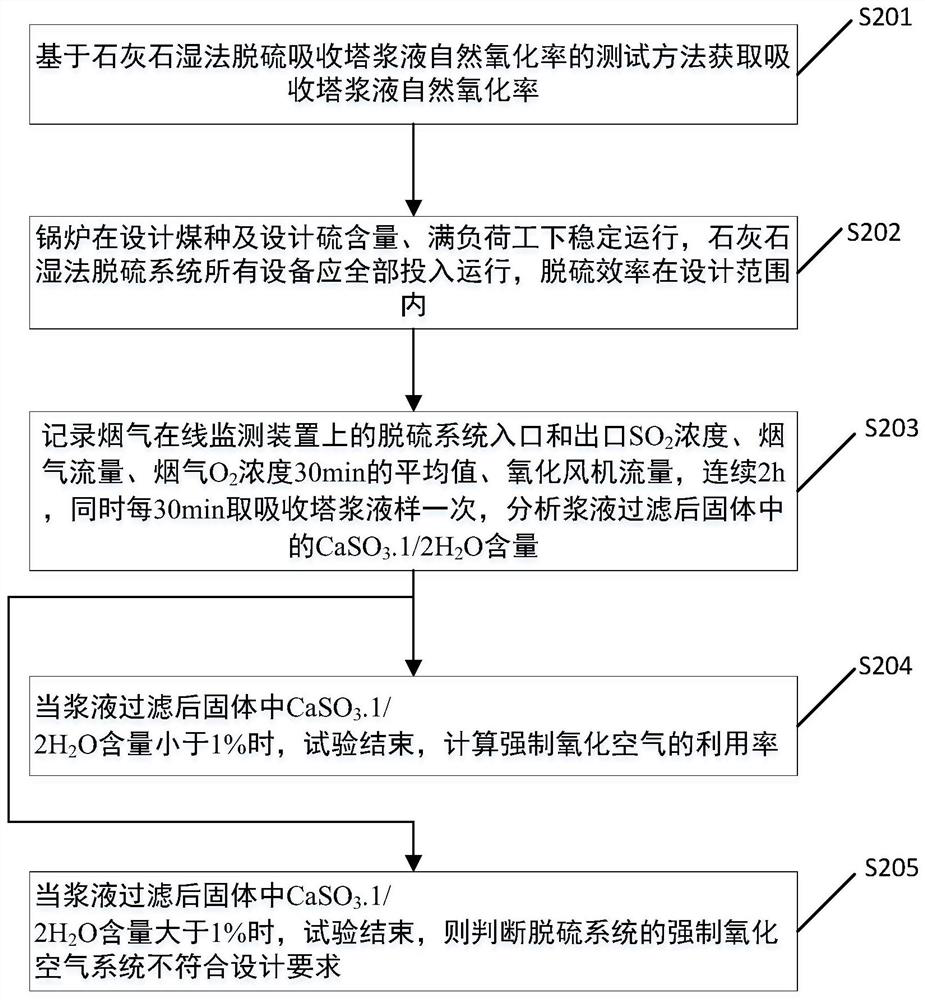

[0037] specific, figure 1 A test method of the utilization of limestone moisture desulfurization forced oxidation air in the embodiment of the present invention includes the following steps:

[0038] S201, test method based on the natural oxidation rate of limestone wet desulfurization absorption tower slurry, obtains natural oxidation rate of absorption tower slurry;

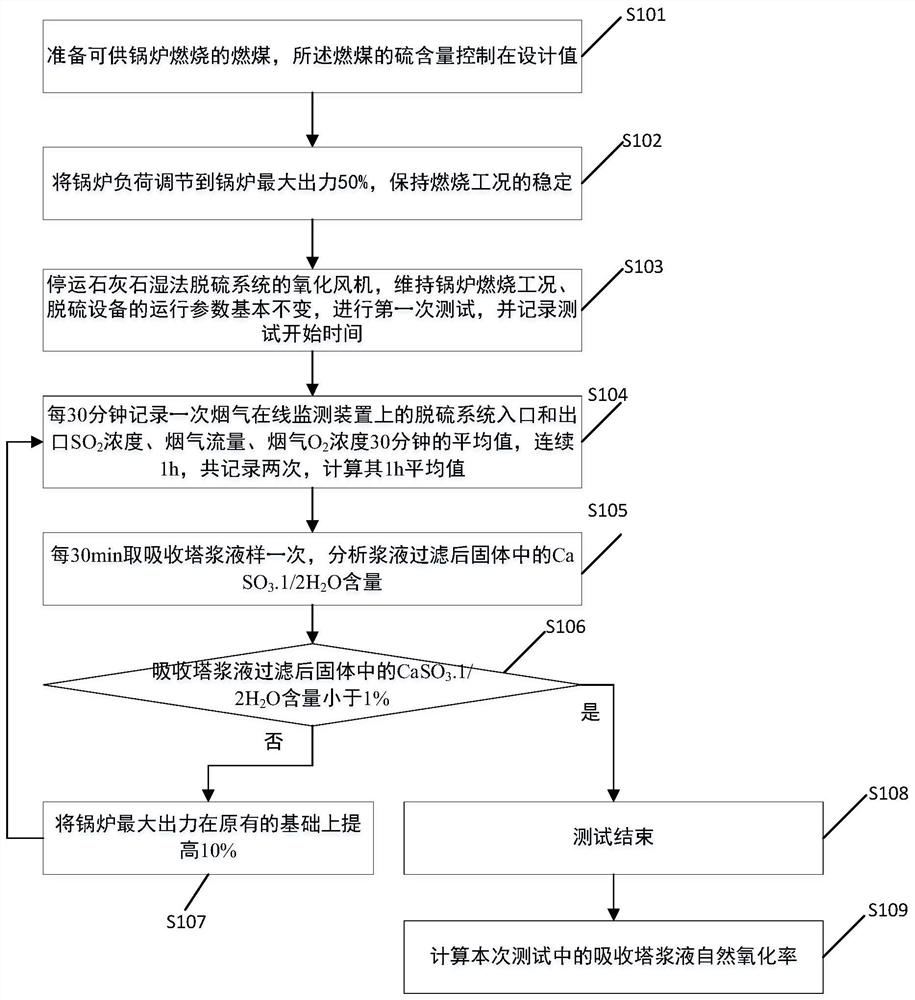

[0039] specific, figure 2 A test method of the limestone moisture desulfurization absorption tower slurry in the embodiment of the present invention is shown, and the specific steps are as follows:

[0040] S101, preparing a coal-burning of boiler combustion, and the sulfur content of the coal is controlled in the design value;

[0041]Specifically, it is prepared to provide a boost for about 6 hours, which coal has a sulfur content of the coal should be controlled at about 60% of the design value, and the other coal coal coal should be substantially the same as the design value.

[0042] S102, adjust the boiler ...

Embodiment 2

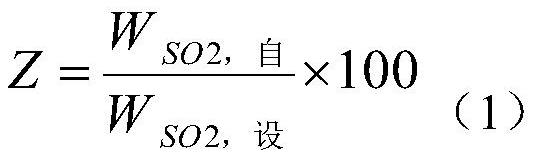

[0074] This detection method includes testing the natural oxidation rate of the slurry by the test method of the natural oxidation rate of limestone wet desulfurization absorption tower; the boiler is stabilized at the design of coal species and design sulfur content (maximum sulfur content), full load conditions (BMCR) Operation, limestone humid desulfurization system All equipment should be operated, its desulfurization efficiency is within the design scope; record of the desulfurization system in the flue gas online monitoring device (CEMS) and exports SO 2 Concentration, flue gas flow, flue gas O 2 The average value of the concentration of 30 min, the flow of the oxidized fan for 2 hours, while absorbing the tetrael liquid sample once every 30 minutes, analyzing the Solid Caso after filtration of the slurry 3 .1 / 2h 2 O content; when the slurry was filtered after the solid was less than 1%, the test ended, used (1), (2), calculated the utilization of the oxidation air; when t...

Embodiment 3

[0102] Testing of the Limestone Wet Flue Gas Desulfurization System of 330MW Units in Guangxi Power Plant Absorption Tower of Mandatory Oxidation Air

[0103] (11) 330MW unit of Guangxi, 330MW unit, using limestone humid flue gas desulfurization system, and a total of 4 layers of spray layers (correspondingly 4 slurry circulation pumps), the design value of the sulfur content in the coal is 2.83%, and the SO is treated in the flue gas 2 The concentration FGD entrance design value is 6800mg / m 3 (Standard, dry, O 2 6%), design processing of flue gas volume 1089235M 3 / h (standard, dry, o 2 6%), its emissions SO 2 Concentration allows emission standards less than 400 mg / m 3 (Standard, dry, O 2 6%). For each absorbent tower sets two oxidized air systems (one-to-use), each oxide flow rate is 19000m 3 / h (stated).

[0104] (12) Improved flue gas desulfurization system (FGD), export measurement flue gas SO 2 The concentration, flue gas volume of flue gas was verified, and its error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com