Method for testing content of combustible materials in limestone wet desulphurization slurry solid

A technology of wet desulfurization and testing methods, applied in the direction of weighing by removing certain components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

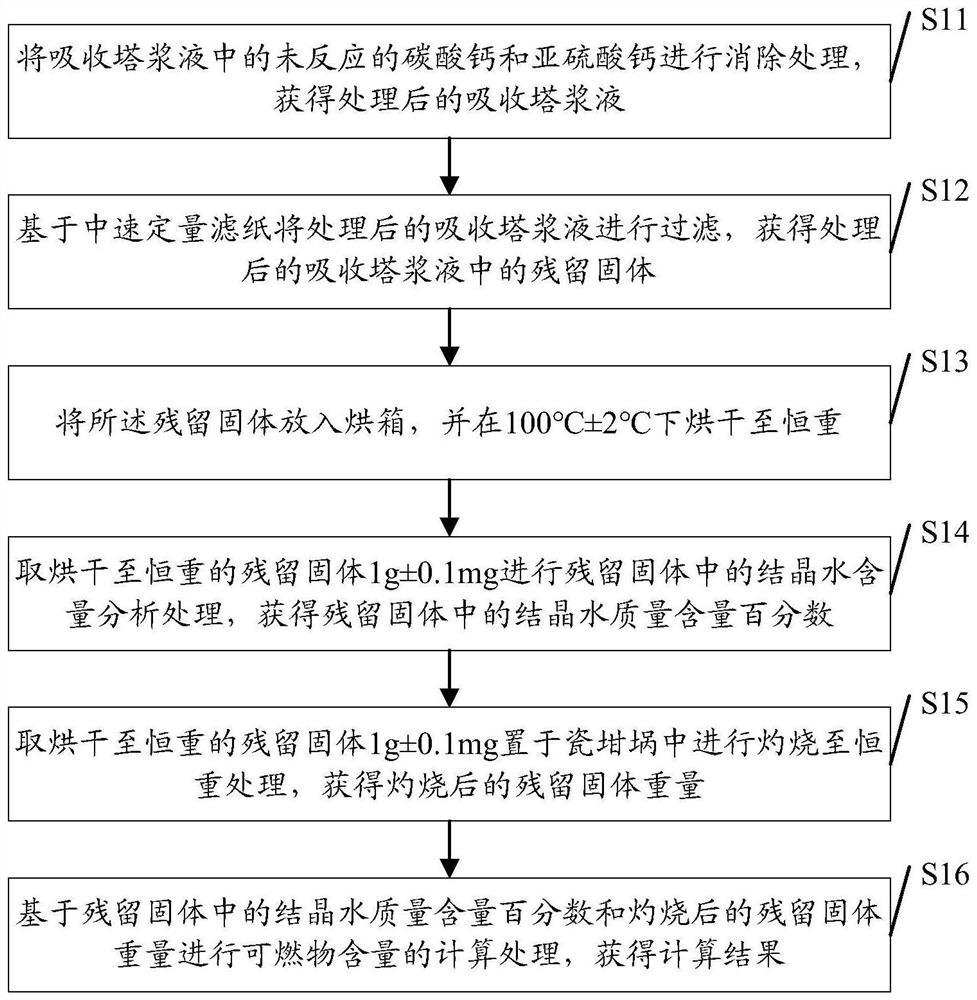

[0034] see figure 1 , figure 1 It is the test method for the combustible content in the limestone wet desulfurization slurry solid in the embodiment of the present invention.

[0035] Such as figure 1 Shown, a kind of test method of combustible content in limestone wet desulfurization slurry solid, said method comprises:

[0036] S11: Eliminate the unreacted calcium carbonate and calcium sulfite in the absorption tower slurry to obtain the treated absorption tower slurry;

[0037] In the specific implementation process of the present invention, the unreacted calcium carbonate and calcium sulfite in the absorption tower slurry are eliminated, and the treated absorption tower slurry is obtained, including: obtaining the sampling absorption tower slurry, adding H at the first preset concentration 2 o 2 Carry out calcium sulfite removal treatment to obtain a first mixed slurry; add hydrochloric acid of a second preset concentration to the first mixed slurry according to a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com