Preparation method of fly-eye lens with free-form surface substrate

A curved surface compound eye and lens technology, which is applied in the direction of lenses, optics, instruments, etc., can solve the problems of increasing the difficulty and cost of production, and achieve the effects of reducing production cost, simple operation and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

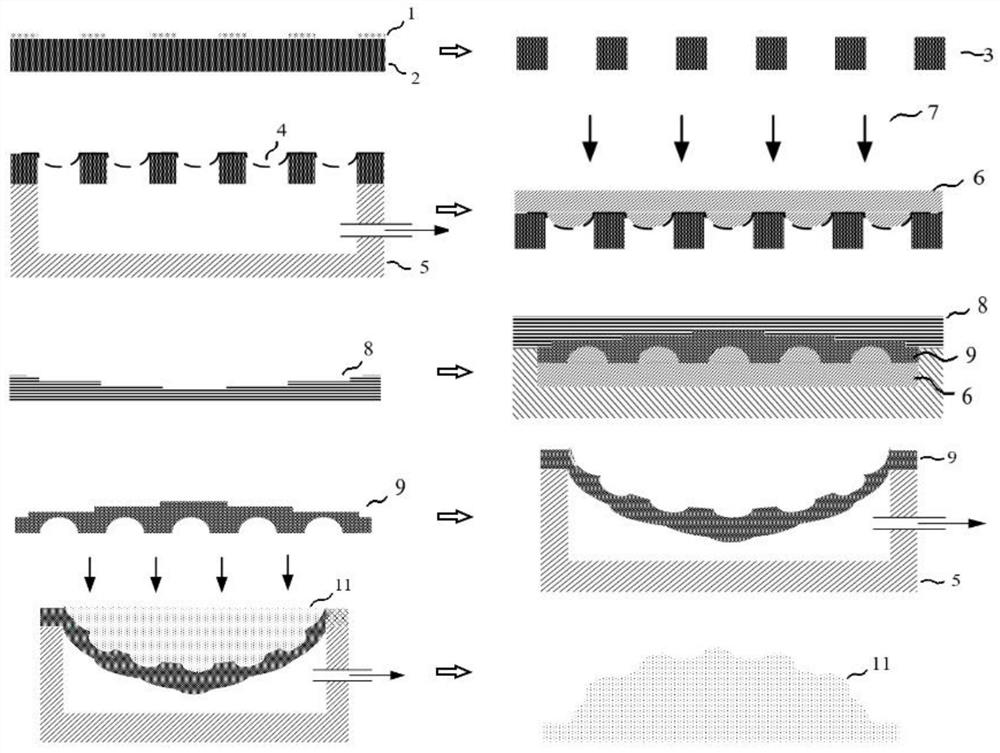

[0030] figure 1 It is a schematic flowchart of a method for preparing a fly-eye lens with a free-form surface substrate according to an embodiment of the present invention.

[0031] Such as figure 1 As shown, the preparation of the fly-eye lens with controllable surface includes the following steps:

[0032] S1: transfer the pattern of the patterned photoresist mask 1 to the substrate of the silicon wafer 2, and carve it into through holes to obtain the microhole array 3 of the silicon wafer 2;

[0033] S2: Cover the prepared PDMS film evenly on the microhole array 3, place it on the plane suction mold 5, and control the negative pressure of the plane suction mold 5 to obtain the The first PDMS concave film 4 in the shape of a sub-eye is required; the air pressure in the air pressure chamber is kept stable, and the second PDMS concave film 9 can be obtained by using the first PDMS concave film 4 to inject glue, cover plate, and unmold.

[0034] The substrate is a silicon wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com