Tillage and soil preparation homogenizing tillage implement

A tillage machine tool and homogenization technology, which is applied in the fields of tillage machine tools, agricultural machinery and implements, agricultural machinery, etc., can solve problems such as inconsistent degrees of fineness of straw and soil, improve operation quality and adaptability, and reduce manpower input and time cost, and the effect of improving maintenance flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

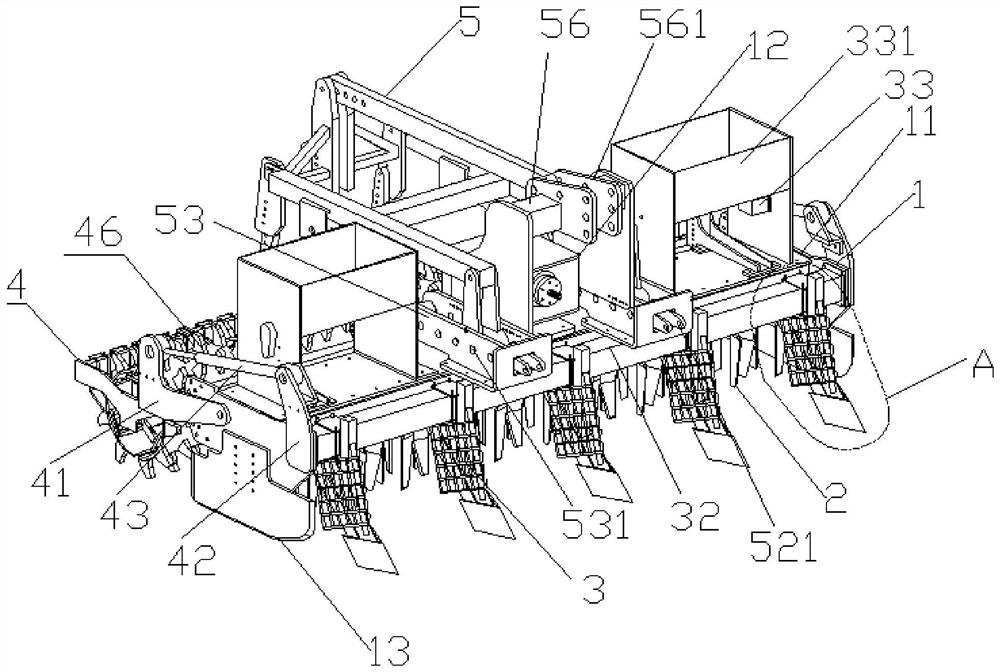

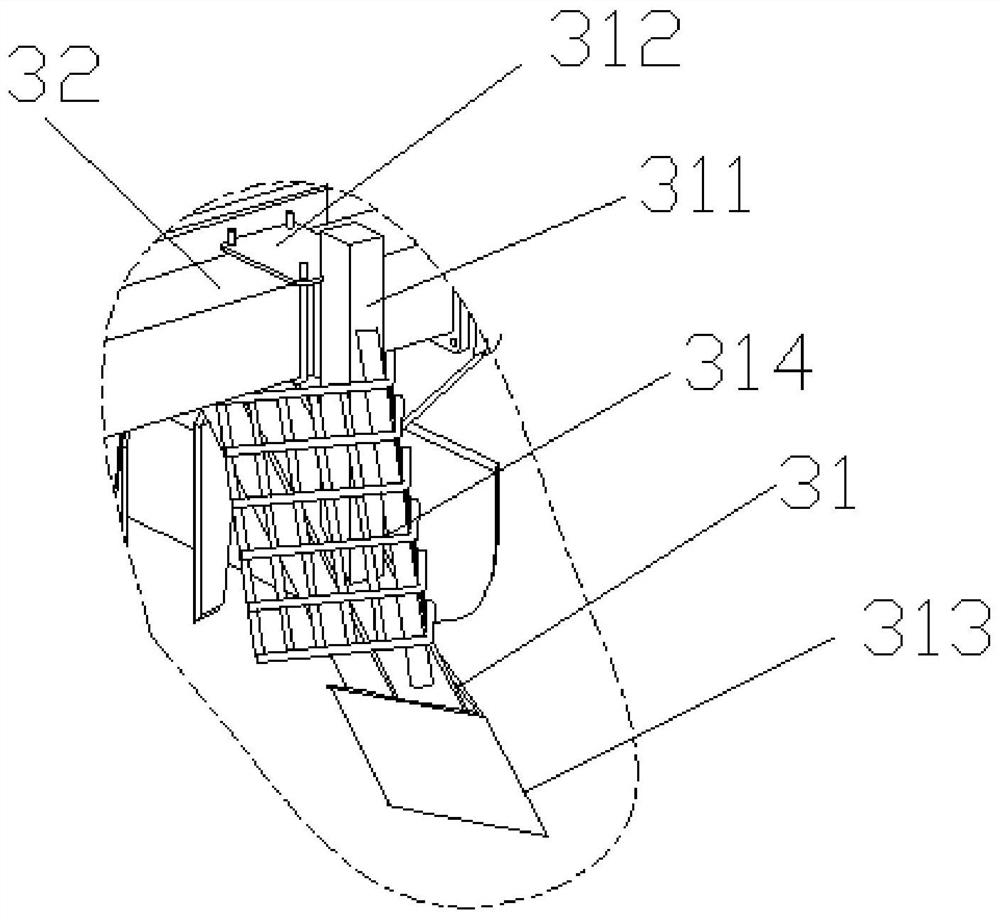

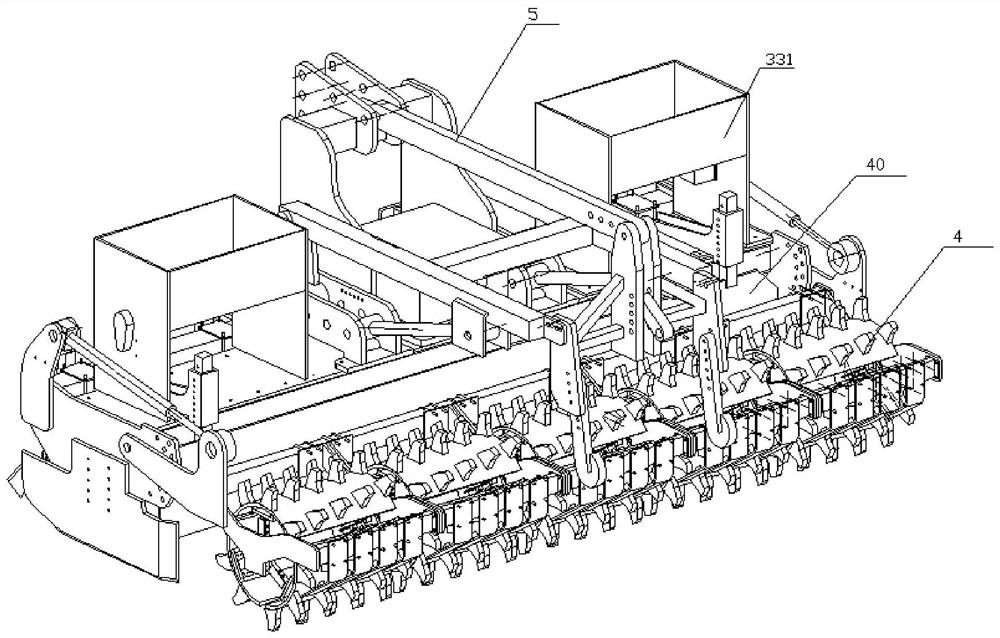

[0033] see Figure 1 to Figure 10 , a homogeneous tillage machine for tillage and preparation, comprising a power box assembly 1, a rotary tillage assembly 2, a fertilization assembly 3, a broken soil compaction assembly 4 and a suspension assembly 5.

[0034] The top middle of the power box 11 of the power box assembly 1 is connected with a reduction box 12, and a horizontal power connecting plate 111 is fixed inside the power box 11, and the power connecting plate 111 is provided with a plurality of spaced apart mounting holes. A chuck 112 is installed in the mounting hole of the power connecting plate 111, the upper end of the chuck 112 extends above the power connecting plate 111, and the lower end of the chuck 112 extends below the power connecting plate 111 and passes through Screws are fixed on the power connecting plate 111, and a thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com