Large round billet continuous casting foot-crossing roller type crystallizer electromagnetic stirrer and process

An electromagnetic stirrer and electromagnetic stirring technology, used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of air bubbles, subcutaneous inclusions, and the quality of the core of continuous casting billets, so as to reduce external damage and improve the quality of the core. , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

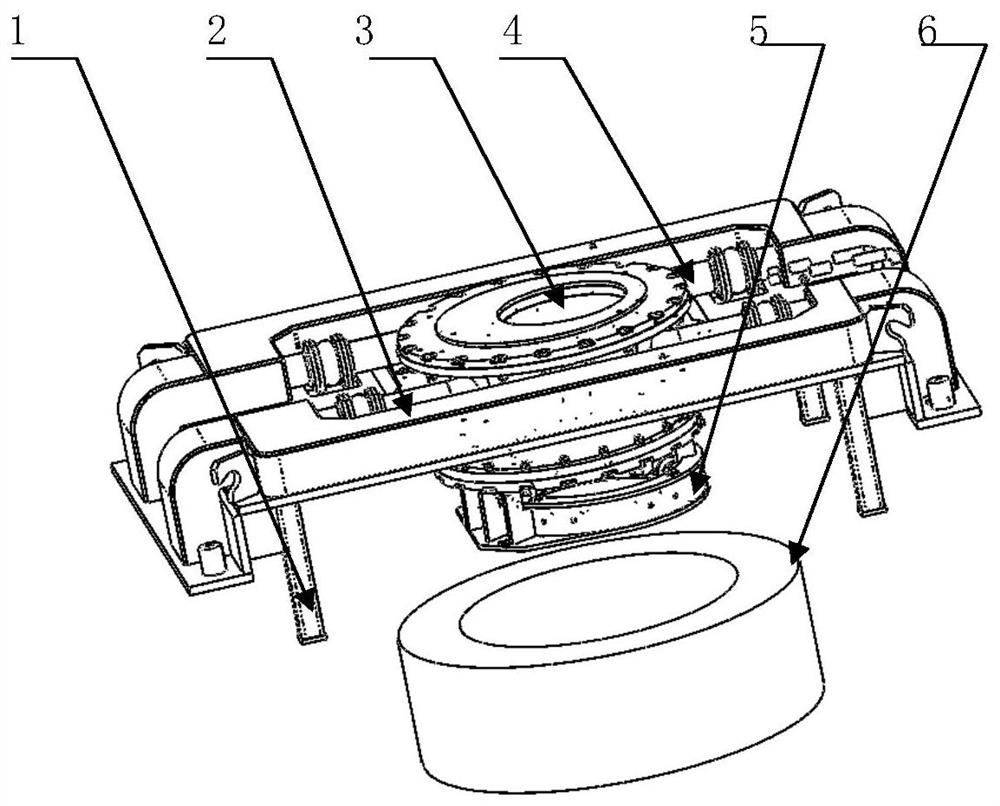

Method used

Image

Examples

Embodiment 1

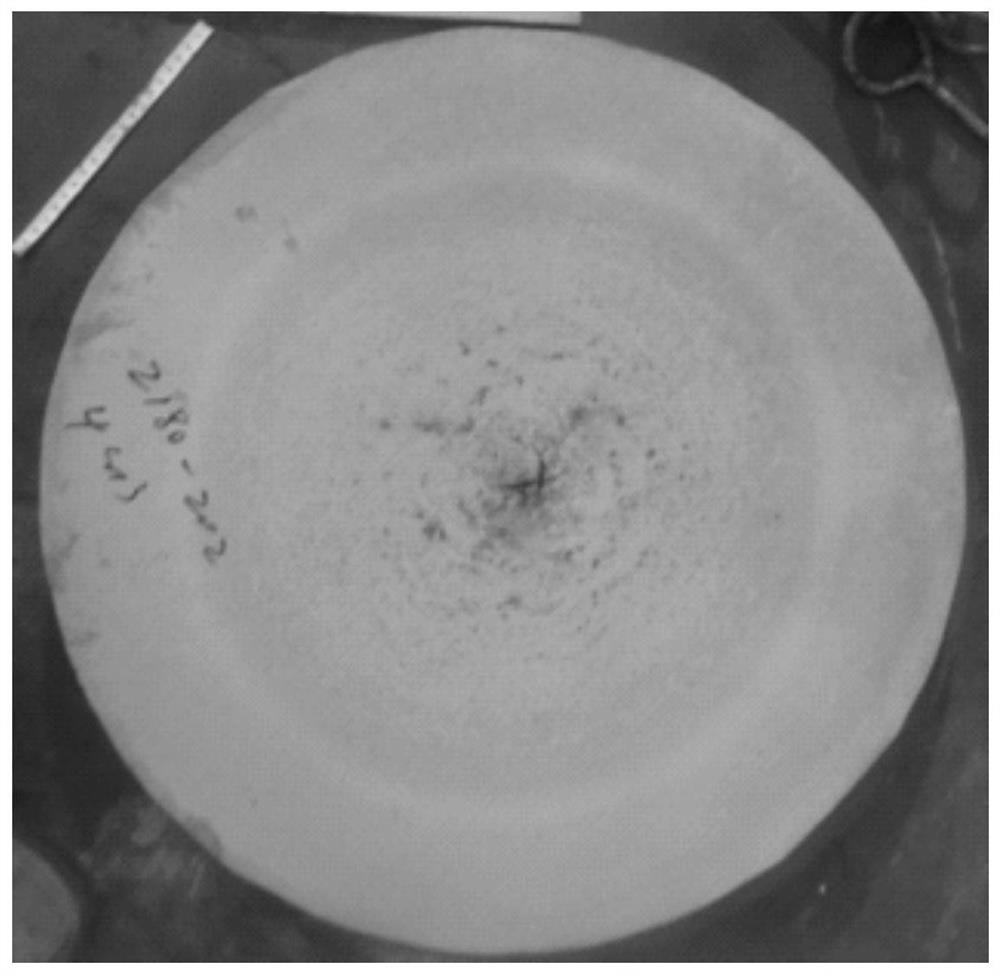

[0035] Brand: Q345+Z35, sample: 17114052535-102

[0036] Crystallizer electromagnetic stirring parameters: 150A / 1.5Hz

[0037] Continuous casting slab low-magnification grade: such as Figure 5 Shown: Medium pine grade 0.5, no other defects such as white bands.

Embodiment 2

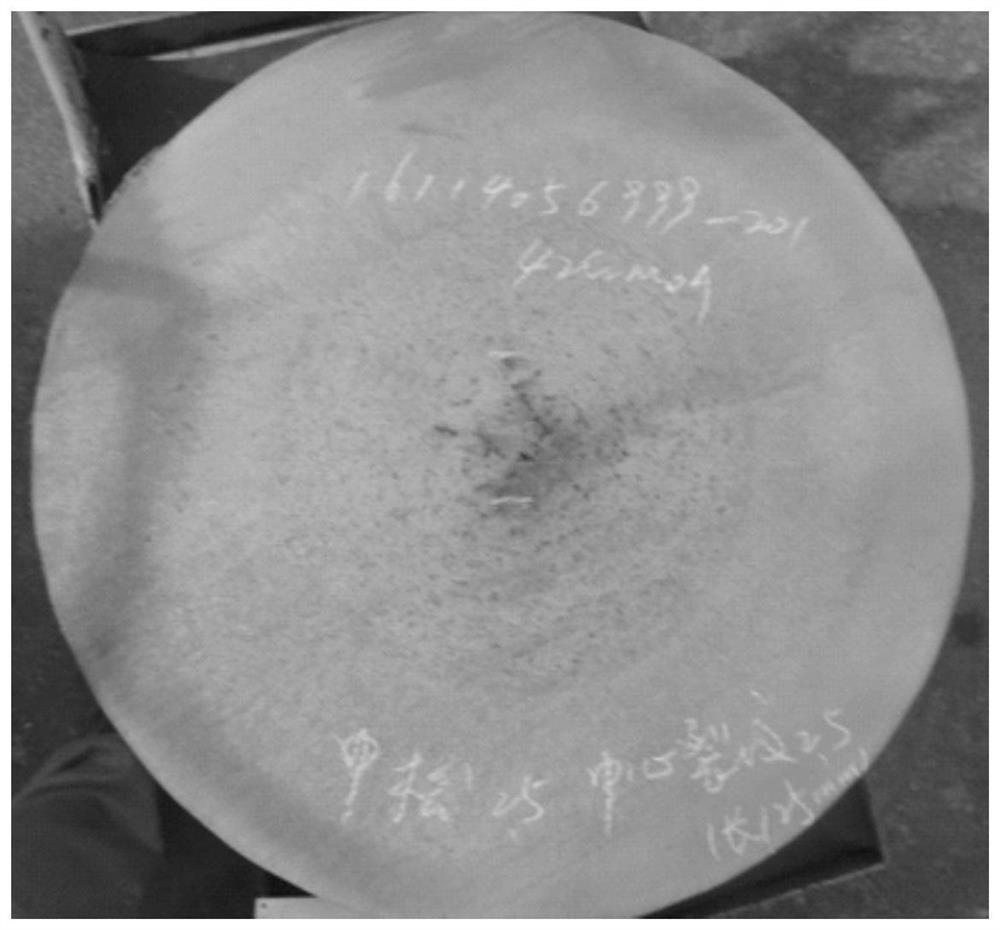

[0039] Grade: 42CrMo4, sample: 17114052030-102

[0040] Crystallizer electromagnetic stirring parameters: 200A / 1.5Hz

[0041] Continuous casting slab low-magnification grade: such as Image 6 Shown: Medium pine 2.0 grade, no white bright belt and other defects.

Embodiment 3

[0043] Brand: 4Cr13, Sample: 17114050502-101

[0044] Crystallizer electromagnetic stirring parameters: 200A / 1.5Hz

[0045] Continuous casting slab low-magnification grade: such as Figure 7 Shown: medium pine 1.5 grade, central crack 3.0 grade, no white bright belt defect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com