A kind of tin material cloisonné enamel color painting production method

A production method and technique of langcai painting, applied in the direction of manufacturing tools, specialized techniques of art painting, decorative arts, etc., can solve the problems of incomplete display of metal filigree, unbeautiful finished products, filigree melting and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

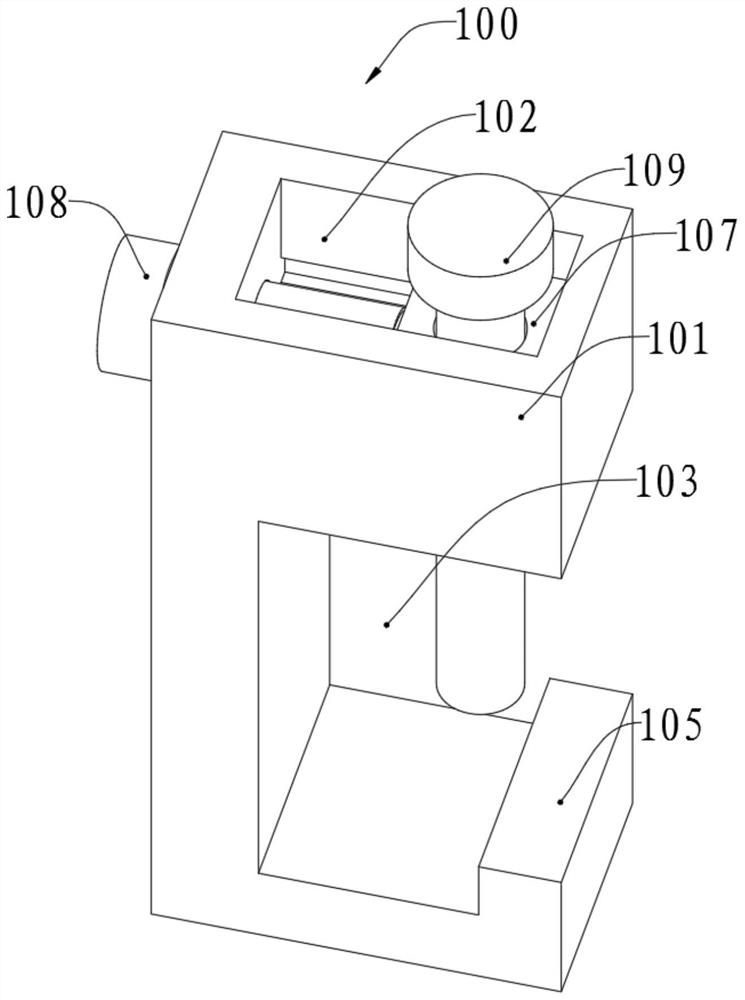

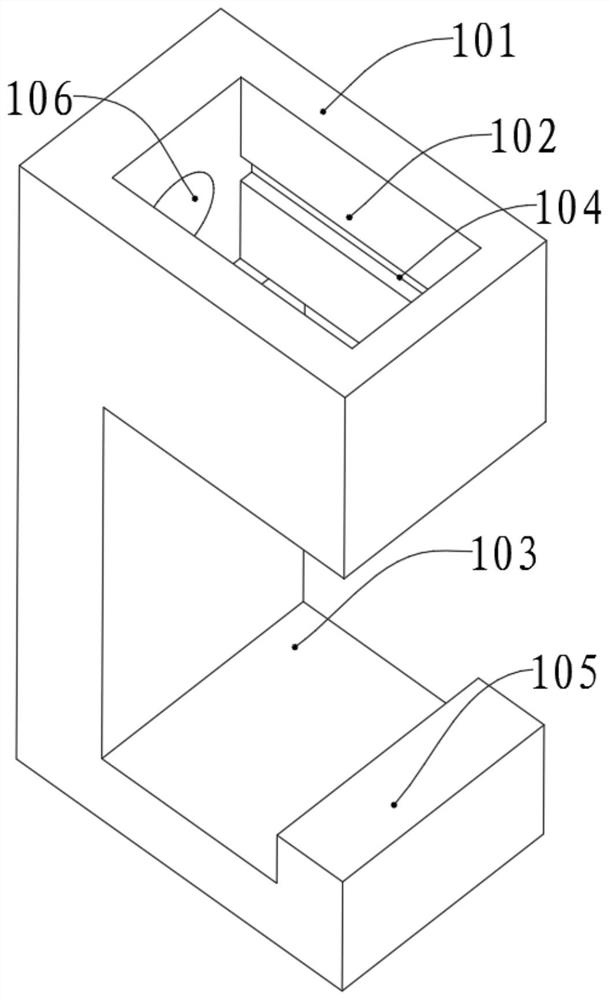

[0039] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

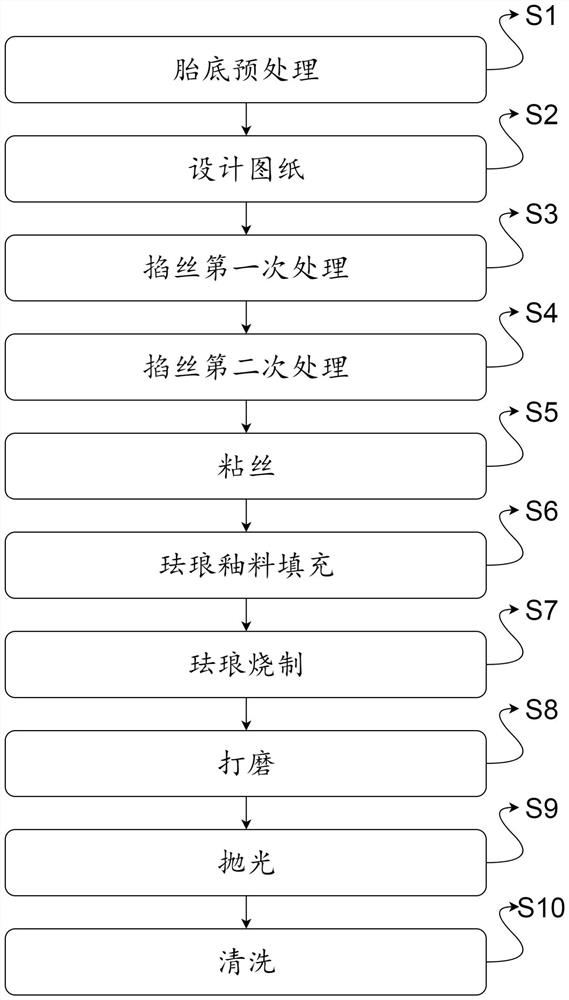

[0040] like Figure 1-6 As shown in the figure, a method for making a tin material cloisonné enamel color painting comprises the following steps:

[0041] S1, pretreatment of the tire bottom, check the tire bottom to confirm that the tire bottom structure is complete and free of defects, use an ultrasonic cleaning machine to clean the tire bottom for the first time, and use alcohol and a brush to clean the tire bottom surface after the first cleaning is completed. The second cleaning is to clean the residual dirt on the surface of the tire bottom. After the cleaning is completed, dry it for later use. By inspecting the tire bottom, the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com