AZO material nano resistive film and preparation method thereof

A resistive film and nanotechnology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of environmental pollution, narrow Zn content range of AZO materials, and high price of film preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will be combined with Figure 5 The present invention is described in detail with specific examples.

[0032] According to one embodiment of the present invention, a kind of preparation method of the AZO material nano-resistance film applied on the microchannel plate comprises the following steps:

[0033] 1) Put the device substrate into the reaction chamber for evacuation, and heat the reaction chamber and maintain the temperature;

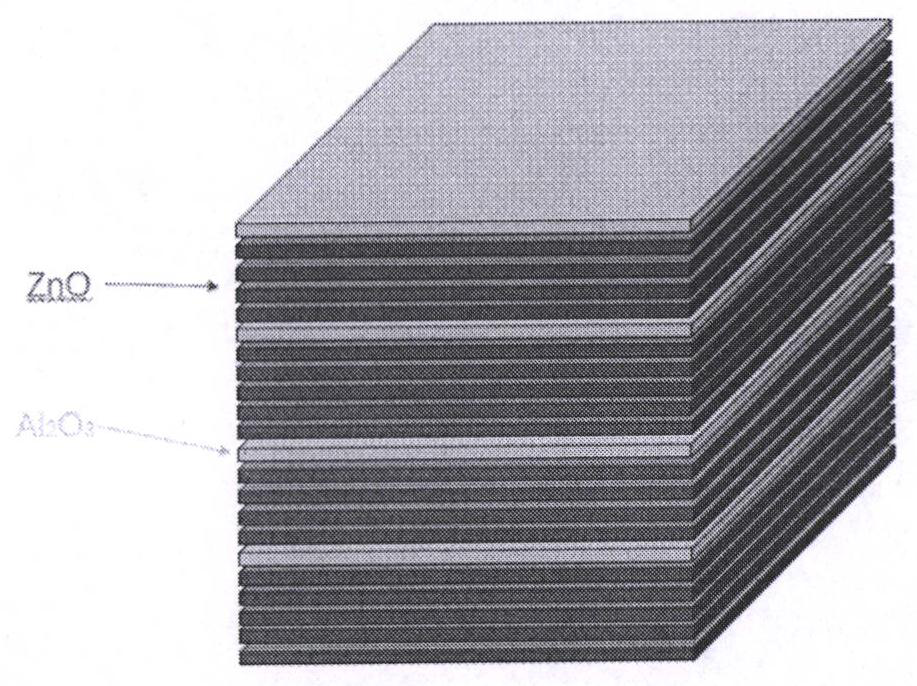

[0034] 2) Set Al 2 o 3 and ZnO atomic layer deposition process;

[0035] 3) Set the Al of the doping process by nesting small loops in large loops 2 o 3 and the atomic layer arrangement sequence of ZnO, so that the total number of atomic layer growth processes satisfies the range of 100 to 1000 for growth.

[0036] 4) Set the temperature of the reaction chamber to anneal the film.

[0037] 5) Growth Al 2 o 3 as the emission layer.

[0038] Further, the device substrate described in step 1) is an insulating micropor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com