Drainage device in building

A drainage device and construction technology, applied in water supply devices, indoor sanitary plumbing devices, buildings, etc., can solve problems affecting the sleep quality of neighbors, loud noise, pipe blockage, etc., to improve drainage efficiency, reduce noise pollution, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

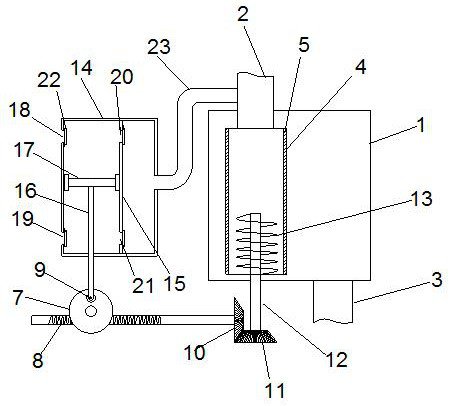

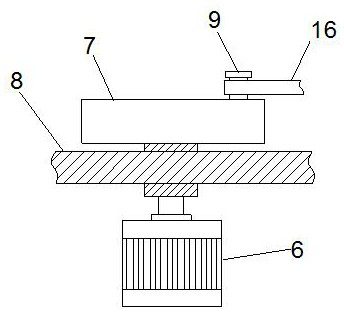

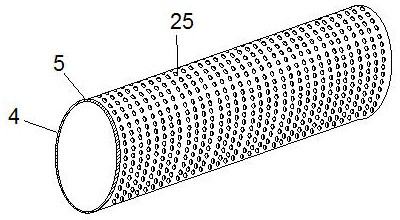

[0039] like Figure 1-5 As shown, a drainage device inside a building includes a casing 1, a downspout 2, and a drainpipe 3; the casing 1 is provided with a rotary drum 4, and the upper end of the rotary drum 4 is connected with a downspout 2, and the rotary The inner side wall of the cylinder 4 is provided with a filter screen 5, and the side wall of the rotating cylinder 4 is provided with a plurality of through holes 25; the casing 1 is in a sealed structure, and the bottom of the casing 1 is connected with the drain pipe 3; The bottom of the cylinder 4 is provided with a rotating shaft 12, the rotating shaft 12 is provided with a helical cutter 13, the other end of the rotating shaft 12 is connected with a second gear 11, the second gear 11 is meshed with the first gear 10, and the first gear 10 is engaged with the second gear 11. A gear 10 is connected with a worm 8, and the worm 8 is matched with a worm wheel 7, which drives the first gear 10 to rotate; the downpipe 2 is...

Embodiment 2

[0042] On the basis of the first embodiment, the air pressure mechanism includes a sealing box 14, and a partition 15 is arranged inside the sealing box 14. One side of the partition 15 is a pressurizing chamber, and the other side of the partition 15 is a The gas collecting chamber; the inside of the pressurizing chamber is provided with a piston plate 17, the piston plate 17 and the inner wall of the pressurizing chamber form an airtight structure through rubber, and the piston plate 17 is slidably connected in the pressurizing chamber; the piston plate 17 One side is connected to the moving rod 16, the moving rod 16 penetrates the sealing box 14, and forms a gap sliding connection with the sealing box 14.

[0043] The other end of the moving rod 16 is connected with a turning block 9, which is arranged on one side of the worm wheel 7, and the turning block 9 and the worm wheel 7 constitute a rotational connection; the turning block 9 is connected to the side wall of the worm...

Embodiment 3

[0046] On the basis of the first embodiment, during the working process of this technical solution, the larger magazines enter the rotating drum 4 with the downpipe 2, and the worm wheel 7 is driven to rotate by the servo motor 6, and the worm wheel 7 drives the worm 8 to rotate; the worm 8 rotates; Drive the first gear 10 and the second gear 11 to rotate, further drive the helical cutter 13 to rotate, and pulverize the larger impurities accumulated in the drum 4; at the same time, the worm gear 7 drives the moving rod 16 and the piston during the rotation process. The plate 17 performs cyclic reciprocating motion in the supercharging chamber. During the upward movement of the piston plate 17, the second intake valve 19 is opened by the action of negative pressure, the gas enters the supercharging chamber from the outside, and the first intake valve 18 is pressurized. The pressure inside the chamber is in a closed state, the first outlet valve 20 is in an open state by the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com