Flexible short section bearing force through axial elastic long rod body

A flexible sub-joint and elastic technology, applied in the direction of drill pipe, measurement, coupling devices, etc., can solve the problems of low efficiency, response delay, increase and jamming, etc., achieve good work reliability, improve adaptability, and enhance coordination effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

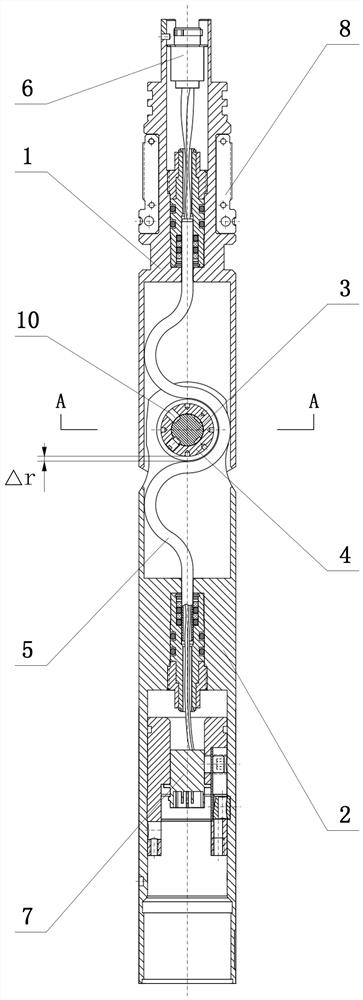

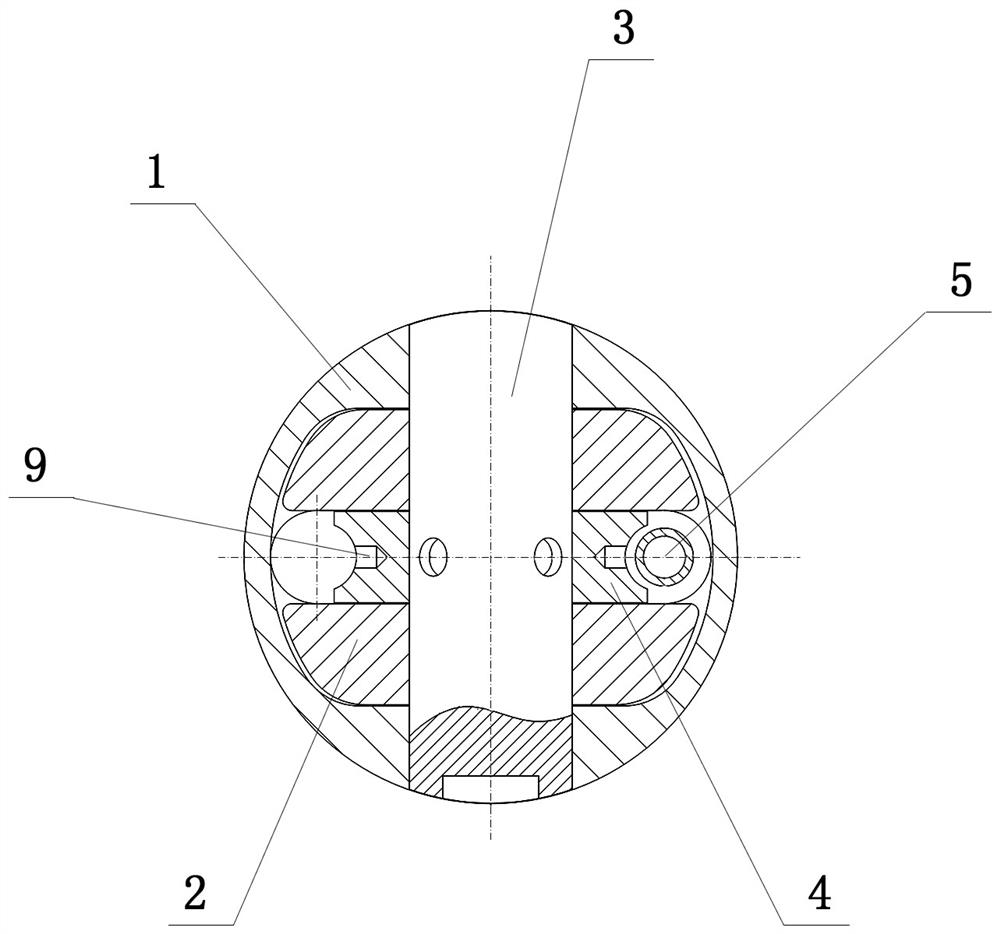

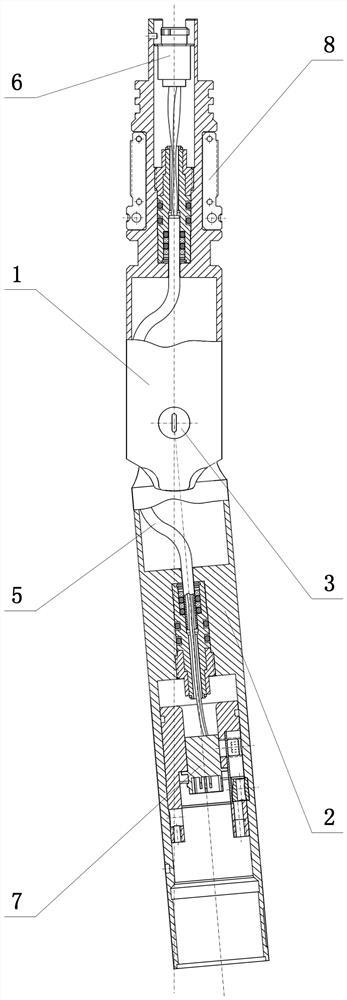

[0014] Below in conjunction with specific embodiment and attached Figures 1 to 5 , to further describe the technical solution claimed in the present invention.

[0015] A kind of flexible sub-joint which is suitable for logging through the drill bit and bears the force of the axially elastic long rod body, such as figure 1 , figure 2 and image 3 As shown, it is composed of an upper joint 1, a lower joint 2, a connecting shaft 3, a support sleeve 4, an elastic pressure bearing rod 5, a wire plug 6 and a wire socket 7, and the upper end of the upper joint 1 is matched with the split screw sleeve 8 An external thread connection structure is formed, the lower end of the lower joint 2 is provided with an internal thread, the lower end of the upper joint 1 and the upper end of the lower joint 2 are hingedly connected to each other by the connecting shaft 3, and the support sleeve 4 is nested On the connecting shaft 3, it is fixedly connected with the connecting shaft 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com