A method for forming an ultra-thin absorbent core

A molding method and absorbent core technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of liquid outflow, poor absorption capacity, poor drainage effect of the absorbent core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

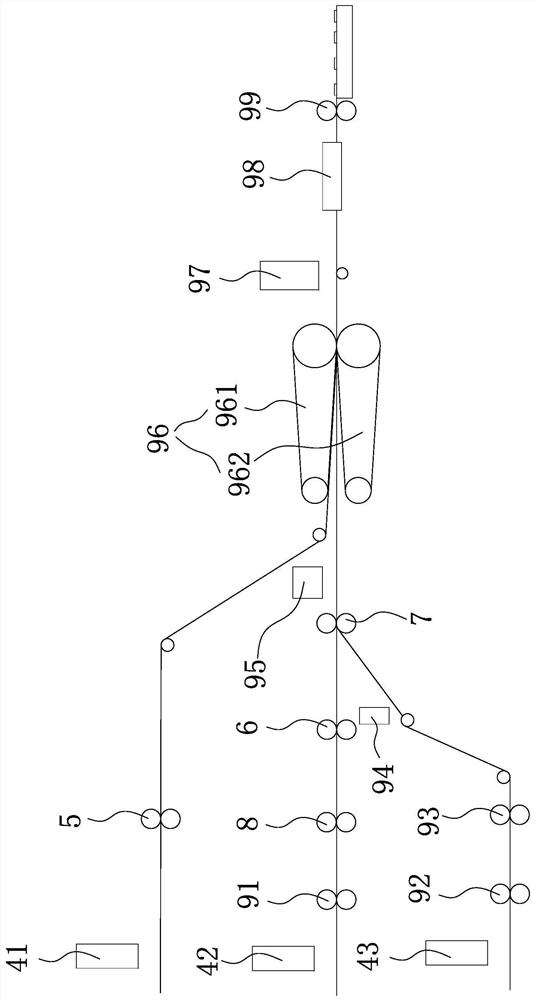

[0044] refer to Figure 1 to Figure 10 , the present embodiment provides a method for forming an ultra-thin absorbent core, comprising the following steps:

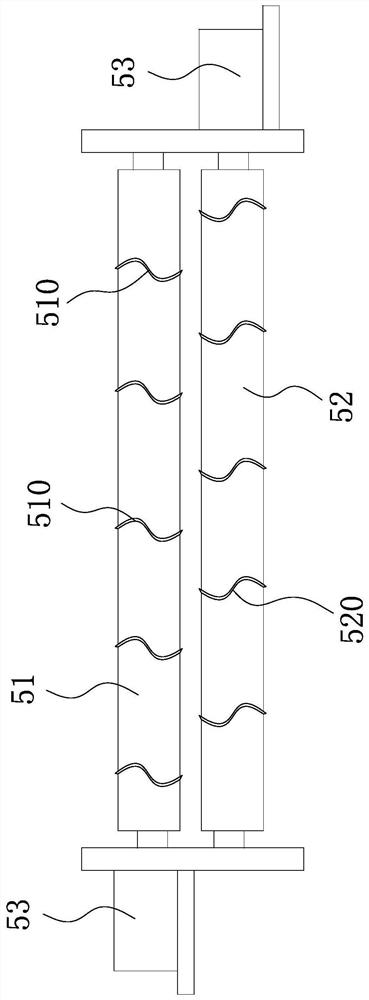

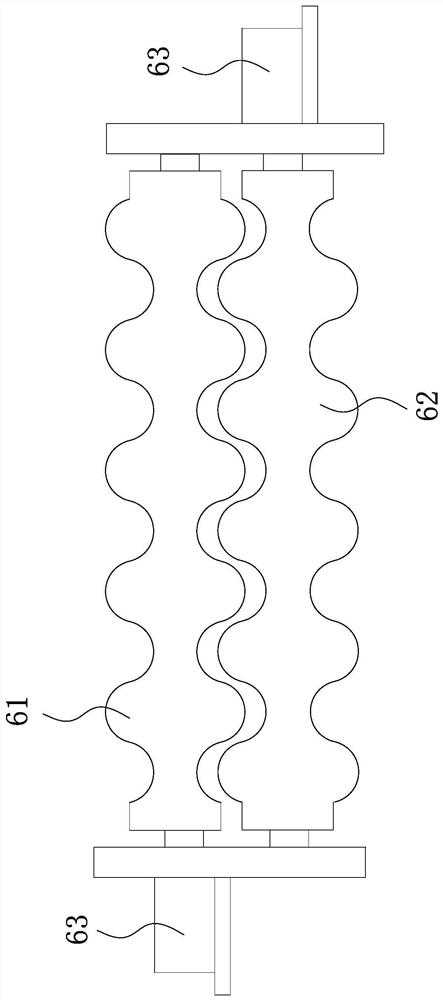

[0045] (1) Manufacture of the upper absorbent core layer 1: the first unloading device 41 cuts the polymer material onto the first polymer carrier to form the upper absorbent core layer 1, and the upper absorbent core layer 1 passes through the first pressing roller mechanism 5 On the upper surface of the upper absorbent core layer 1, five wave-shaped first flow guide grooves 11 are formed, and five wave-shaped second flow guide grooves 12 are formed on the bottom of the upper absorbent core layer 1. The first flow guide grooves 11 and the second flow guide grooves Diversion grooves 12 are arranged alternately, refer to Figure 8 , Figure 8 The five wavy solid lines are the first diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com