Method for detecting deviation of steel strip between cold continuous rolling racks

A technology for cold tandem rolling mills and steel strips, applied in the direction of cleaning methods using gas flow, cleaning methods and appliances, chemical instruments and methods, etc., which can solve problems such as roll sticking to steel, steel strip deviation, and strip breakage in the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

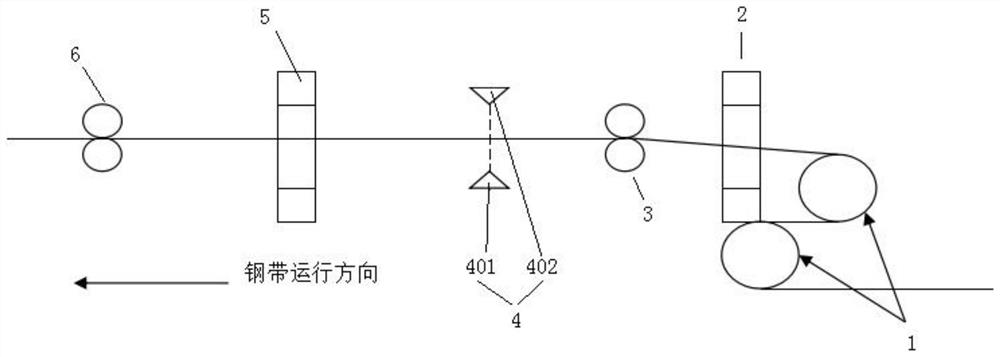

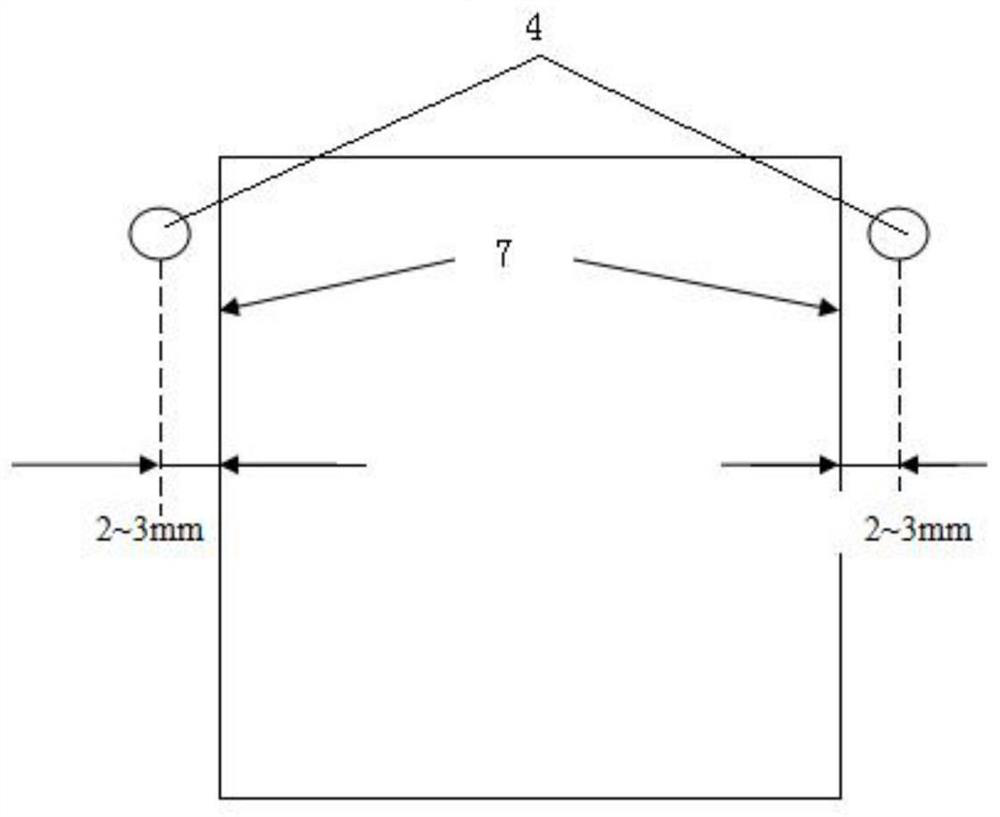

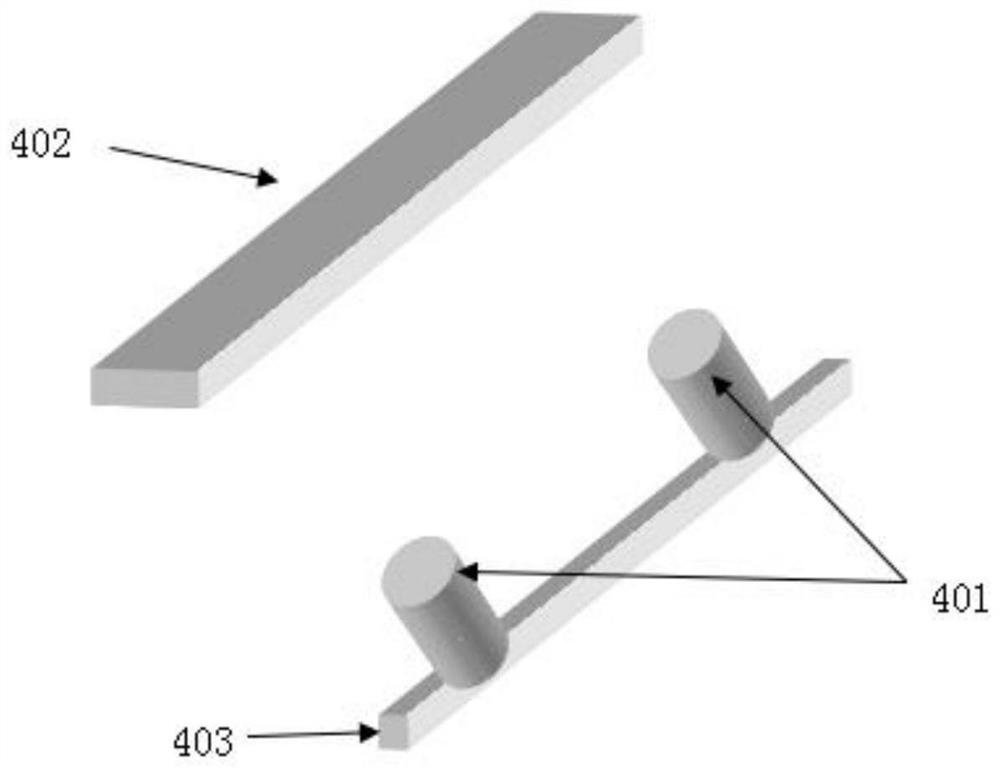

[0023]A method for detecting a steel strip of a cold rolling mill, which is a rack 3 with a rolling mill of the acid rolling unit, and the rolling mill is two frames (that is, the rolling mill 1 rack) mounting grating detector 4 pairs of steel Tested by the edges, the specific configuration locationfigure 1 The emitter 401 of the grating transmits a light source signal, and the receiving pole 402 of the grating receives the light source signal. Under normal production, the grating can induce the signal, once the grating does not induce the signal, indicating that the steel sheet in the frame occurs between the rolling machine frame, and the grating detection, 4 to the mill, the mill, the mill begins to reduce the speed.

[0024]The acid rolling combined unit of acid rolling in the present invention is from the CSP production line or the finished product width does not do excessive adjustment of the production line, according to the width of the raw material, behind the rover 3, at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com