Multi-degree-of-freedom reverse hole forming robot

A robot with a degree of freedom, which is applied in the direction of manufacturing tools, stone processing tools, working accessories, etc., can solve the problems of easy fatigue, high working intensity, and damage to drill bits and motors of drilling tools, so as to expand the working range and reduce Labor intensity, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

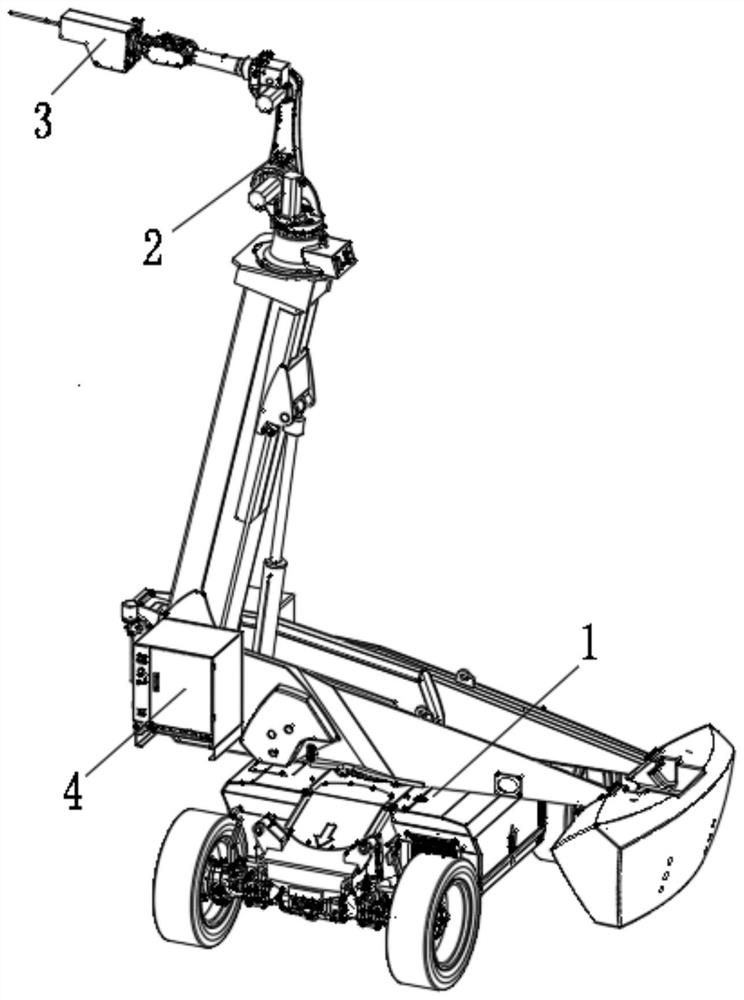

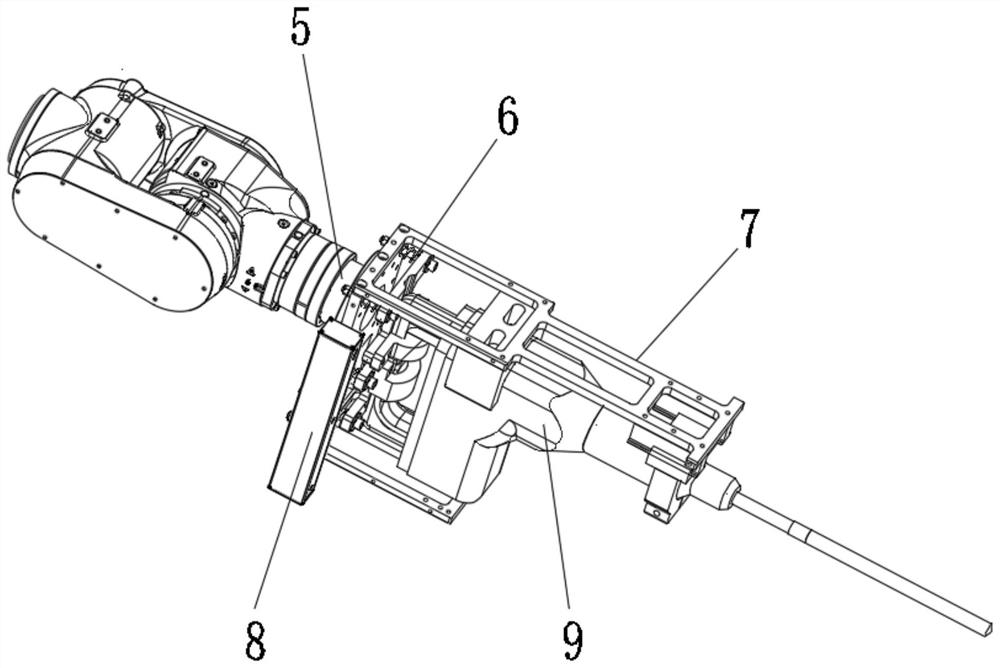

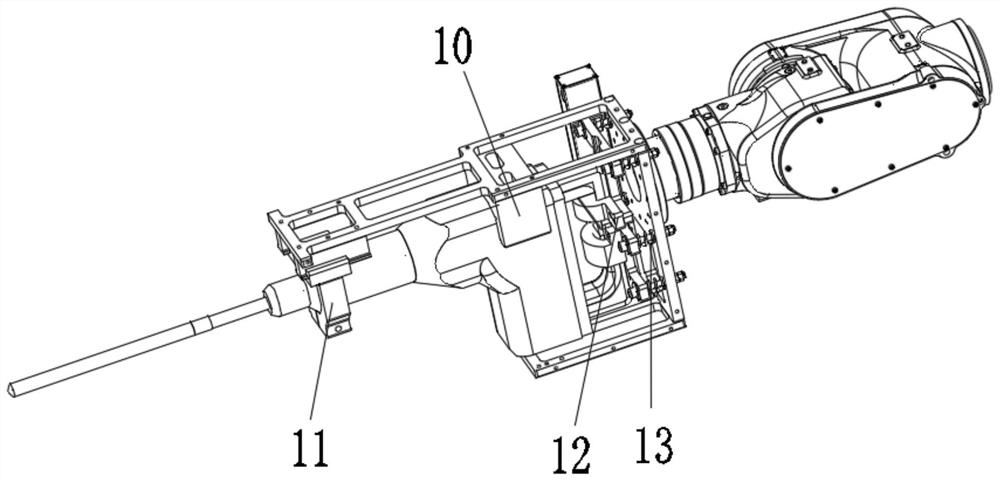

[0027] see Figure 1 to Figure 7, the present invention provides a technical solution: a multi-degree-of-freedom reverse hole-making robot, including an aerial work vehicle 1, a multi-axis mechanical arm 2, and a hole maker 3. The top of the aerial work vehicle 1 is provided with an extension arm, and the extended The top of the arm is equipped with a multi-axis mechanical arm 2. When in use, it can be installed according to actual needs. The hole maker 3 is equipped with different aerial work vehicles and mechanical arms to meet the needs of different working conditions. The aerial work vehicle 1 is in the operator's Under control, carry the multi-axis manipulator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com