Plasma etching enhanced ternary mixed plastic flotation separation method

A plasma and mixed plastic technology, which is used in the flotation separation of plastic mixtures, and plasma etching as a pretreatment field, can solve the problems of low efficiency of manual sorting, and achieve the advantages of easy popularization and application, industrialized large-scale application, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail through specific embodiments below. However, those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products.

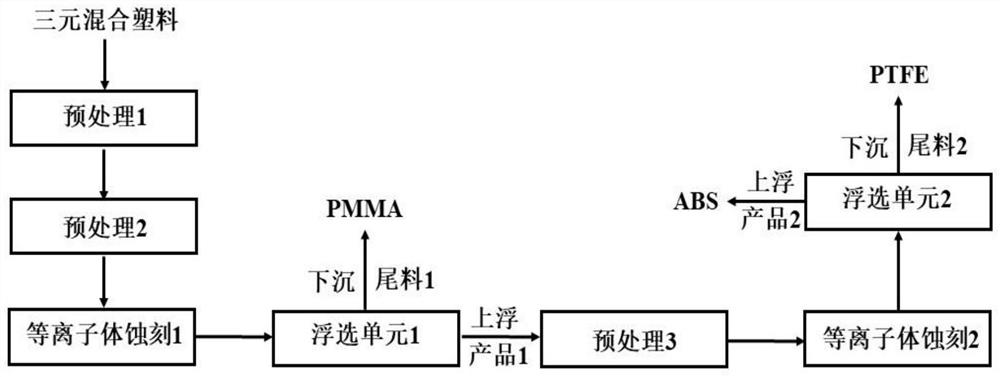

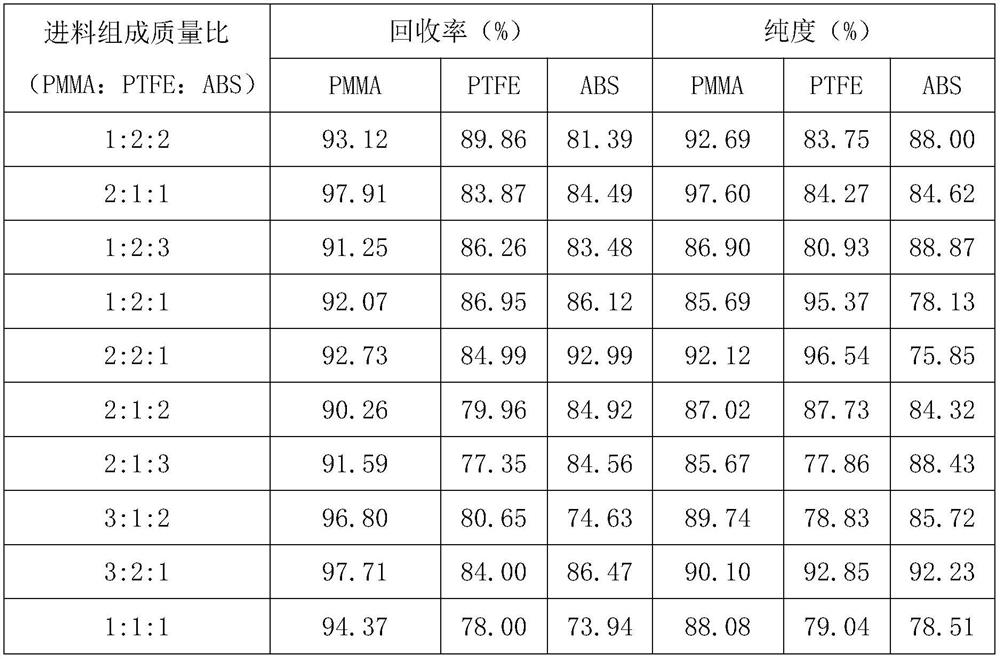

[0029] Such as figure 1 As shown, the method technology of the present invention comprises seven core process links including pretreatment 1, pretreatment 2, plasma etching 1, flotation unit 1, pretreatment 3, plasma etching 2 and flotation unit 2; The seven process links are connected in series and can be operated continuously online; the ternary mixed plastics fed into the pretreatment 1 include polymethyl methacrylate (PMMA), polytetrafluoroethylene (PTFE) and propylene from different sources and mass ratios. Nitrile / butadiene / styrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com