Stone needle fiber yarn and preparation method thereof

A fiber and Bianstone technology, which is applied in the field of Bianstone fiber yarn and its preparation, can solve the problems of inability to perform antibacterial properties, elastic properties, affect the comfort of antibacterial fibers, etc., and achieve the effects of improving antibacterial effect, preventing static electricity, and antibacterial use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] And the preparation method of modified cotton fiber comprises the following steps:

[0041] Step 1, adding 30-60 parts by weight of cotton fibers, 6-12 parts of nanometer stones, 1-3 parts of zinc oxide and 0.5-0.8 parts of fatty acid amide dispersant into the mixer and mixing, keeping Vacuum in the mixer, the relative humidity is lower than 3%, and the mixed material is obtained;

[0042] Step 2, adding the mixed material into a twin-screw extruder for melt extrusion, cooling, casting and shearing to obtain modified cotton fiber particles;

[0043] Step 3. After the modified cotton fiber particles are spun, wound, formed, clustered, guided, first drafted, oil bath, second drafted, third drafted, crimped and relaxed to shape. Obtain modified cotton fiber.

[0044] Correspondingly, the modified spandex fiber includes 30-60 parts by weight of spandex fiber, 3-6 parts of seaweed fiber, 1-2 parts of ferric oxide and 0.5-0.8 parts of fatty acid amide dispersant.

[0045] ...

Embodiment 1

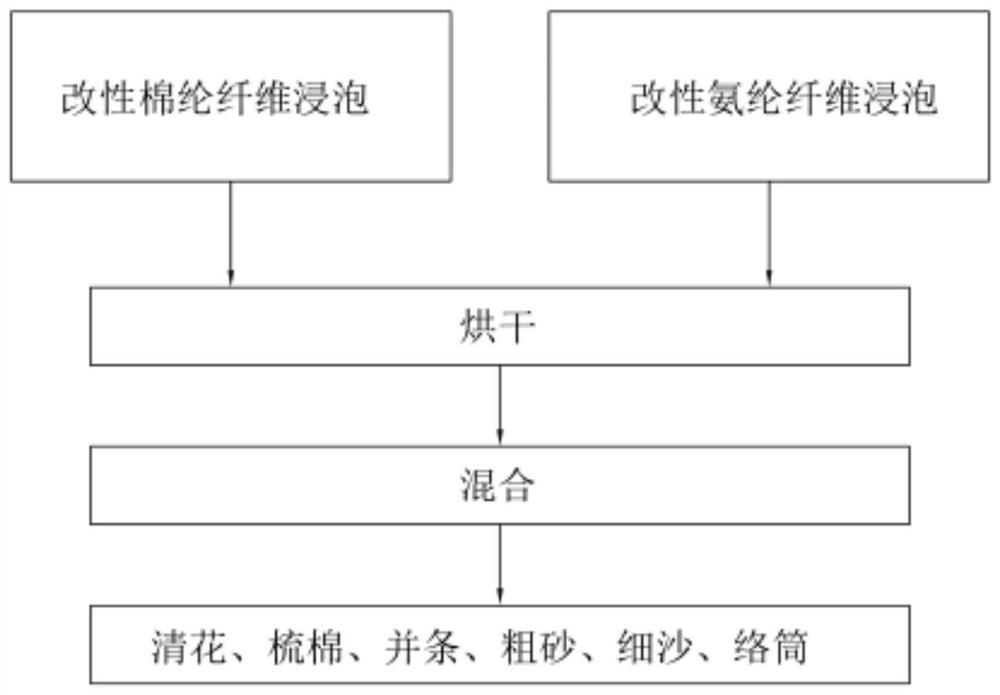

[0056] like figure 1 As shown, a meteorite fiber yarn includes at least one synthetic sub-thread blended with modified cotton fiber, modified spandex fiber and cashmere. Wherein, the ratio of modified cotton fiber, modified spandex fiber and the cashmere is 10:2:1 by weight.

[0057] It should be noted that the modified cotton fiber includes 30 parts by weight of cotton fiber, 6 parts of nanometer stone, 1 part of zinc oxide and 0.5 part of fatty acid amide dispersant.

[0058] And the preparation method of modified cotton fiber comprises the following steps:

[0059] Step 1. Add 30 parts by weight of cotton fiber, 6 parts of nanometer stone, 1 part of zinc oxide and 0.5 part of fatty acid amide dispersant into the mixer and mix, keep the vacuum in the mixer, and the relative humidity Below 3%, get mixed material;

[0060] Step 2, adding the mixed material into a twin-screw extruder for melt extrusion, cooling, casting and shearing to obtain modified cotton fiber particles;...

Embodiment 2

[0074] like figure 1 As shown, a meteorite fiber yarn includes at least one synthetic sub-thread blended with modified cotton fiber, modified spandex fiber and cashmere. Wherein, the ratio of modified cotton fiber, modified spandex fiber and the cashmere is 13:3:1 by weight.

[0075] It should be noted that the modified cotton fibers include 45 parts by weight of cotton fibers, 9 parts of nanometer stones, 2 parts of zinc oxide and 0.65 parts of fatty acid amide dispersant.

[0076] And the preparation method of modified cotton fiber comprises the following steps:

[0077] Step 1. Add 45 parts by weight of cotton fibers, 9 parts of nanometer stones, 2 parts of zinc oxide and 0.65 parts of fatty acid amide dispersant into the mixer and mix, keep the vacuum in the mixer, and the relative humidity Below 3%, get mixed material;

[0078] Step 2, adding the mixed material into a twin-screw extruder for melt extrusion, cooling, casting and shearing to obtain modified cotton fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com