Method for realizing high-rise deflection monitoring based on laser spot center positioning mode

A center positioning and laser spot technology, applied in the field of measurement, can solve the problems of high cost of intelligent total stations, wide sources of GPS data errors, and difficult data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

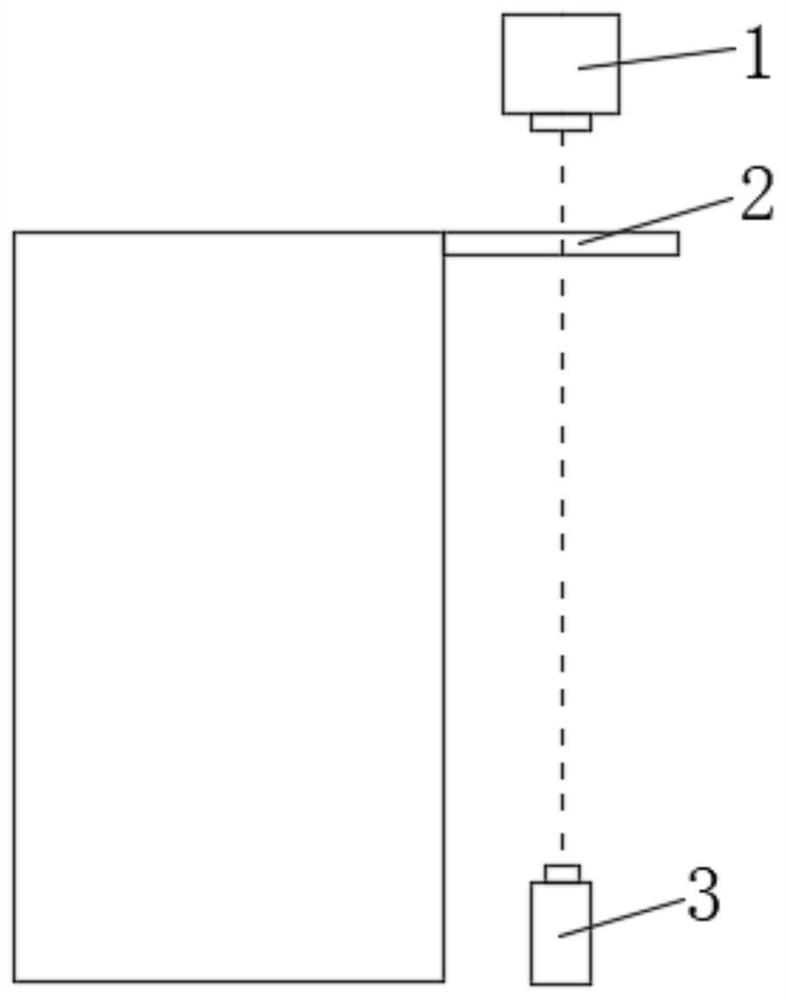

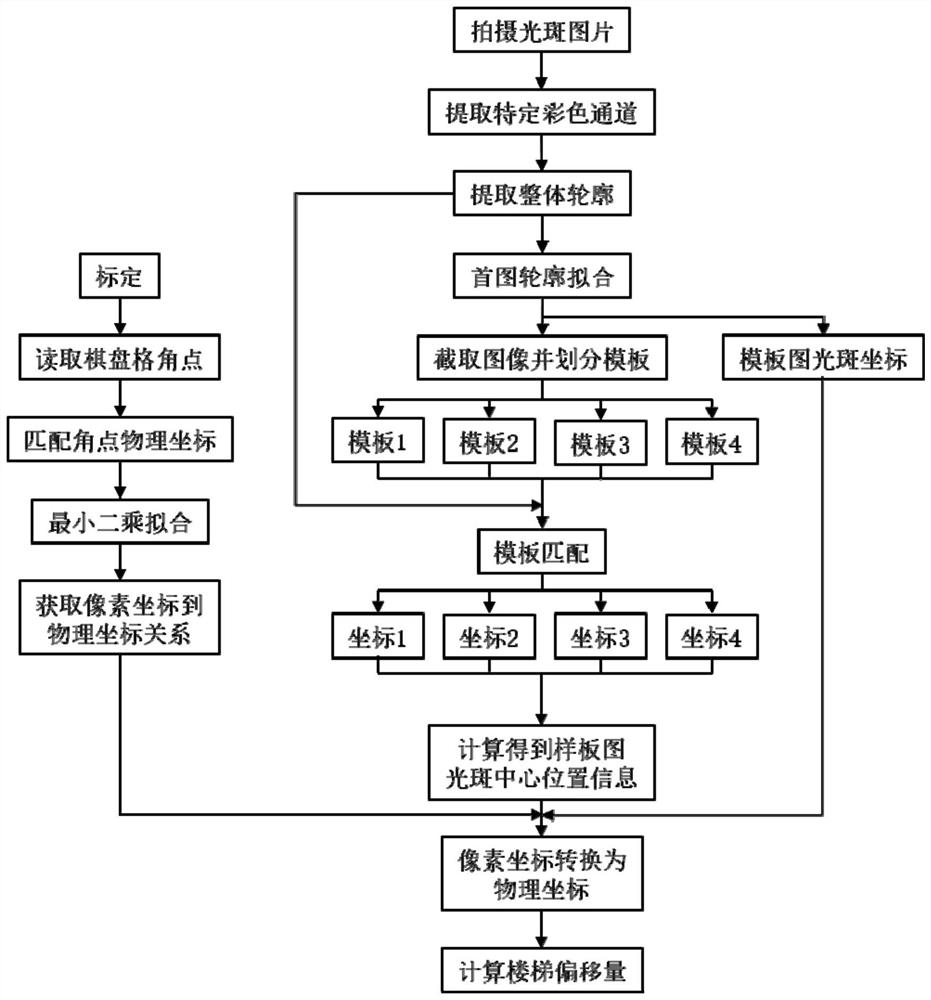

[0046] see Figure 1-3 , a method for realizing high-rise deflection monitoring based on a laser spot center positioning method, comprising the following steps:

[0047] S1. Calibrate the camera 1 in the image acquisition system. The calibration process includes the following steps:

[0048] (1) Fix camera 1, fix a checkerboard target on the side facing camera 1, adjust the focus of camera 1 until camera 1 can clearly capture the target pattern;

[0049] (2) read the pixel coordinates of the corner points of the checkerboard;

[0050] (3) Take any corner point on the checkerboard as the coordinate origin, and obtain the two-dimensional physical coordinates of the corner point on the checkerboard plane;

[0051] (4) Use the least square method to carry out polynomial fitting to obtain the mapping relationship from pixel coordinates to physical coordinates;

[0052] S2. Remove the checkerboard target, and install the light screen 2, that is, the translucent acrylic board, on ...

Embodiment 2

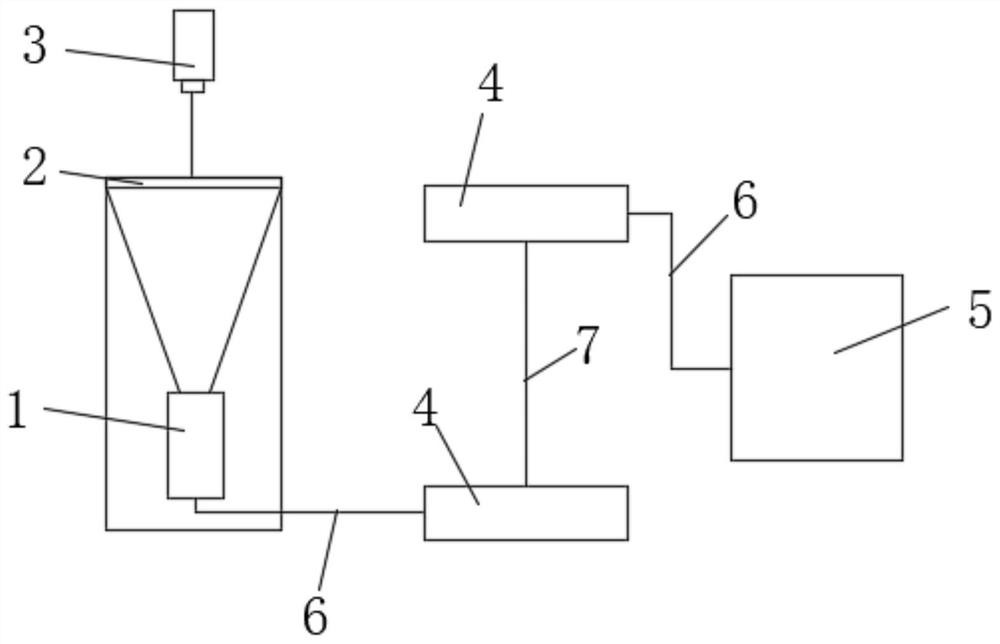

[0075] Such as figure 1 As shown, the displacement monitoring device of the present invention is composed of a camera 1, a laser 3 and an optical screen 2 to form an image acquisition unit, and realizes the conversion of the network cable 6-optical fiber 7-network cable 6 through the optical fiber 7 receiver 4 and the optical fiber 7 transmitter, and completes image acquisition from end-to-end transmission. Although the building body may form a certain deflection when it is swaying, the central position of the light spot captured by the camera 1 will not change with the change of the building body deflection. At the same time, since the variation of the deflection is small, it will not affect the imaging of the spot captured by the camera 1 , so for this measurement method, the variation of the deflection can basically be ignored and not recorded.

[0076] Such as figure 2 As shown, the structure of the present invention is: the laser light emitted by the laser 3 is receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com