Permanent magnet fault-tolerant vernier rim propulsion motor with optimized consequent pole rotor surface shape

A rotor surface, permanent magnet fault-tolerant technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, magnetic circuit rotating parts, etc., can solve the problem of low sine degree of back electromotive force and large number of pole pairs of permanent magnets , The utilization rate of permanent magnets is not high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

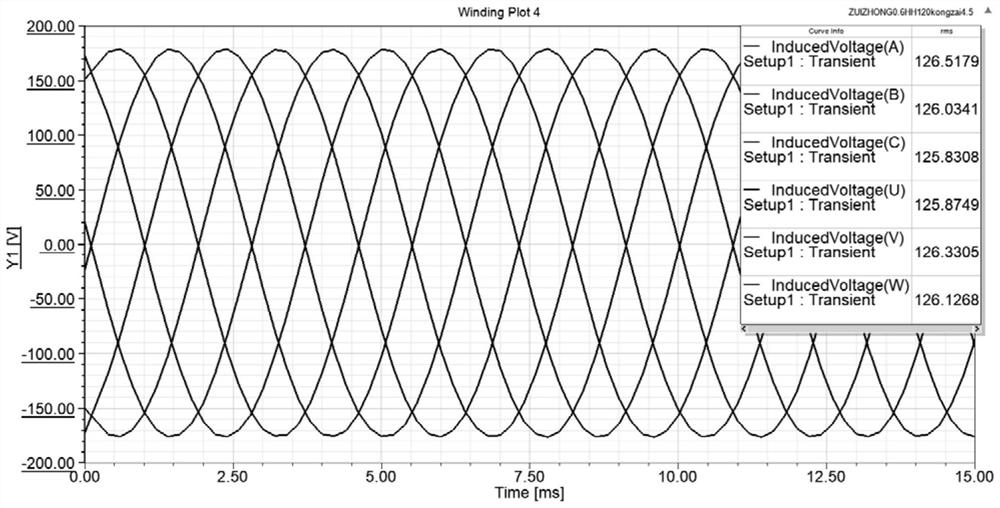

Examples

Embodiment Construction

[0032] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

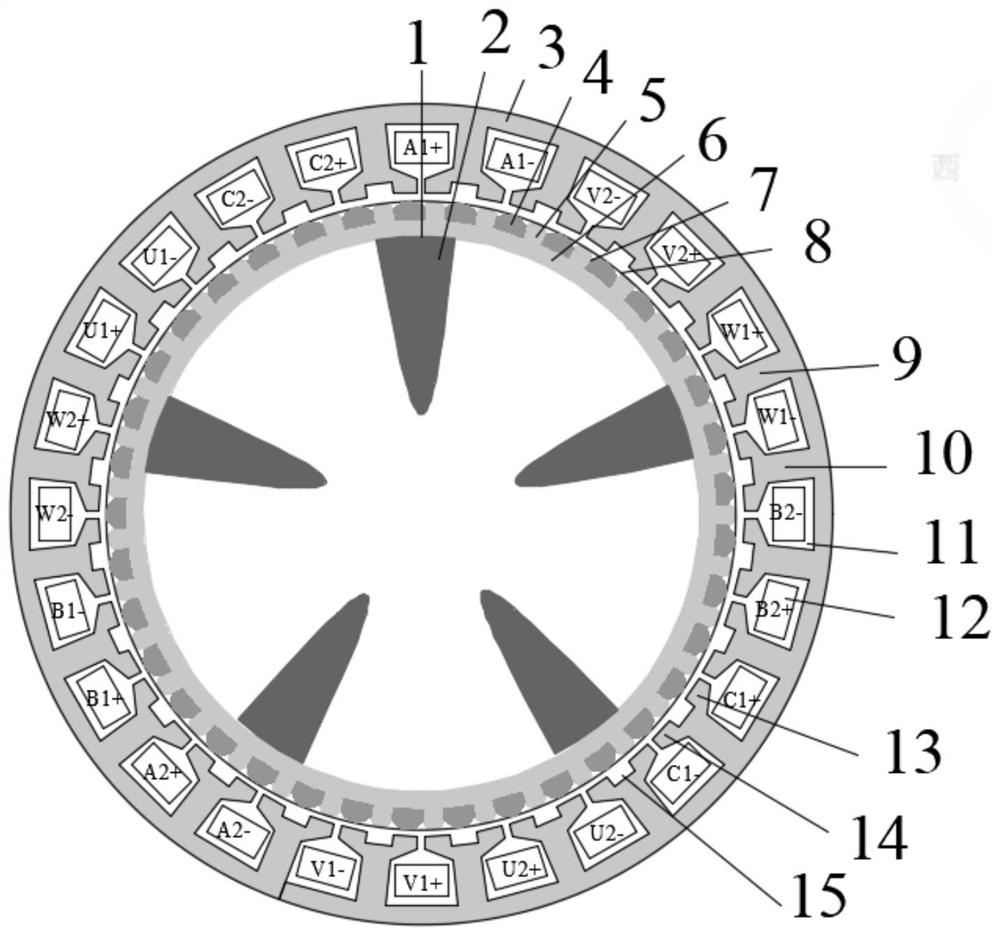

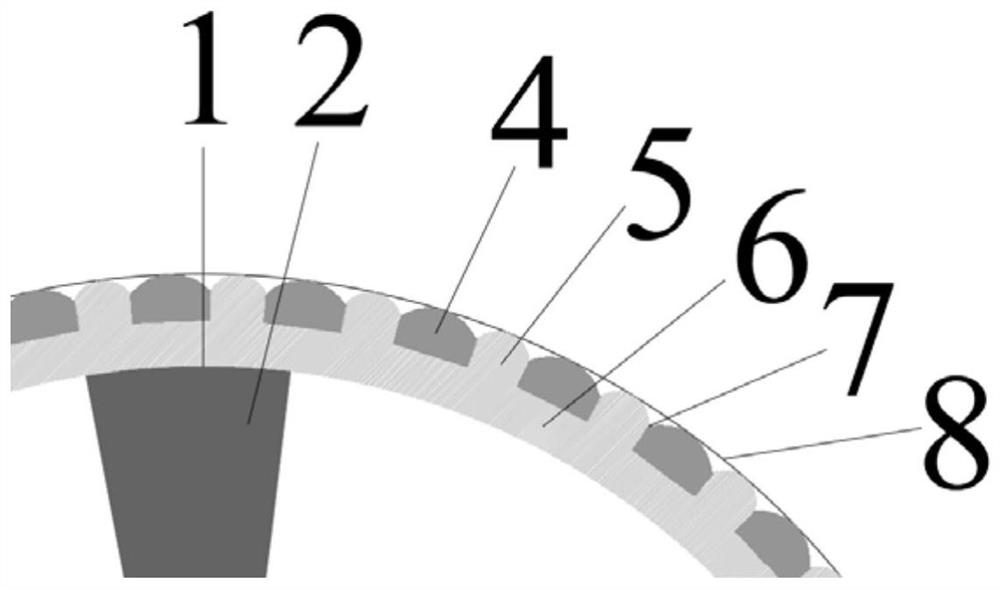

[0033] figure 1 For the permanent magnet fault-tolerant vernier rim propulsion motor optimized for the surface shape of the alternating pole rotor of the present invention, figure 2 Partial enlarged view of the alternating pole rotor optimized for the surface shape; a permanent magnet fault-tolerant vernier rim propulsion motor with optimized surface shape for the alternating pole rotor, including rotor 1, propeller 2 and stator 3;

[0034] The rotor 1 includes a unipolar permanent magnet 4, a rotor tooth 5 and a rotor yoke 6;

[0035] The rotor teeth 5 are evenly distributed on the rotor yoke 6, a rotor slot is formed between every two adjacent rotor teeth 5, and the unipolar permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com