Method and system for identifying gas film hole penetration area by using high-speed camera, and medium

A high-speed camera and air film hole technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of complex structure of turbine blade cavity, clean filling material, incomplete filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

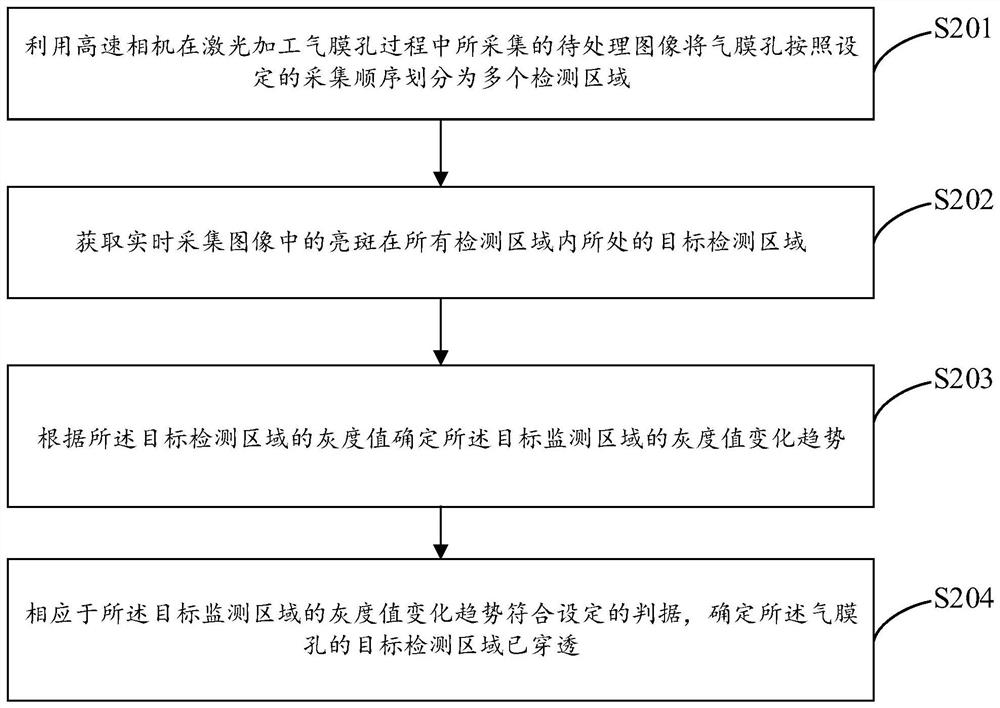

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

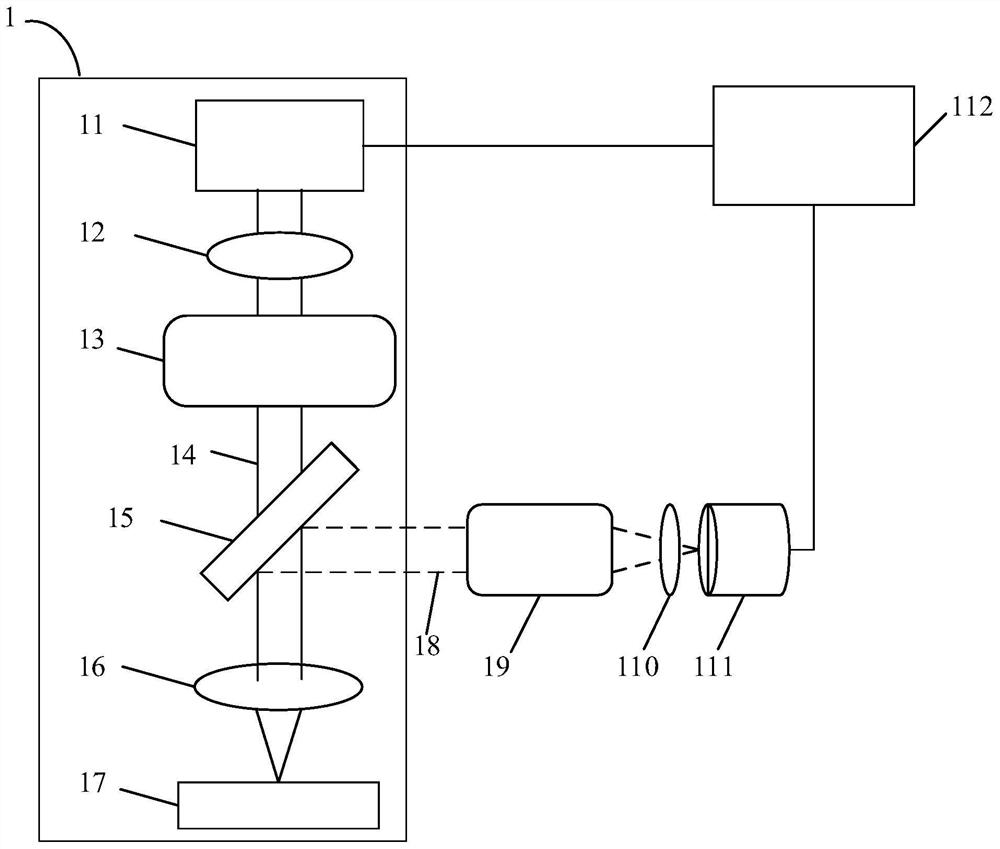

[0036] see figure 1 , which shows a laser processing equipment 1 capable of implementing the technical solution of the embodiment of the present invention, such as figure 1 As shown, in the laser processing equipment 1, the laser beam generated by the laser 11 passes through the laser shaping part 12 and the rotary cutting scanning module 13 and then irradiates on the beam splitter 15, thereby forming the processing optical path 14; wherein, the laser shaping part 12 can make The laser beam is more uniform, and the beam expansion rate of the laser beam can also be controlled; the rotary cutting scanning module 13 can make the laser beam irradiate according to the set processing optical path 14; the beam splitter 105 transmits the laser beam in the processing optical path 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com