Transformer substation foot-type robot, inspection system and method

A technology for robots and substations, applied in motor vehicles, electrical components, switch devices, etc., can solve problems such as inability to work, single leg structure, poor walking ability, etc., to improve versatility, improve movement stability, and enhance adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

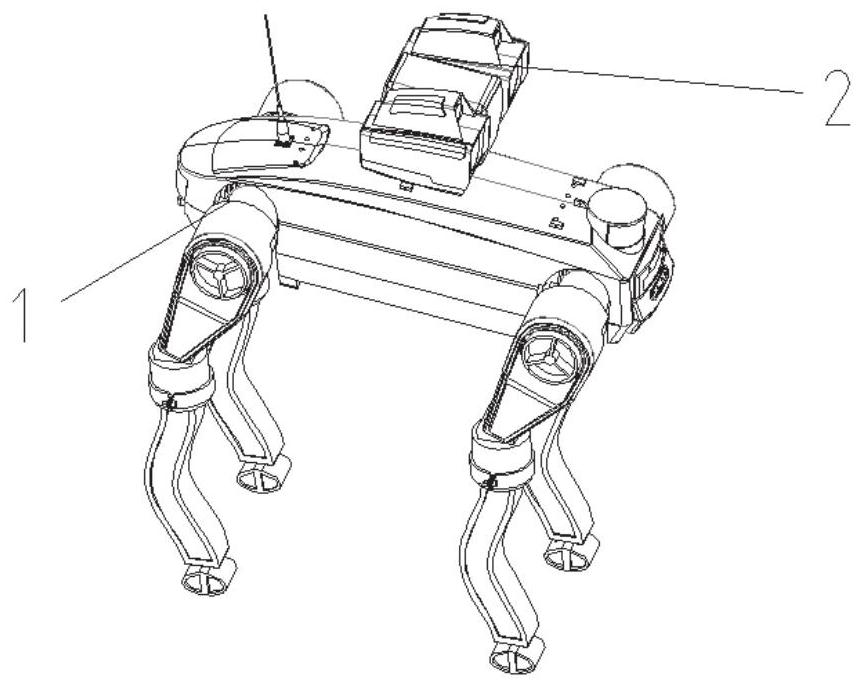

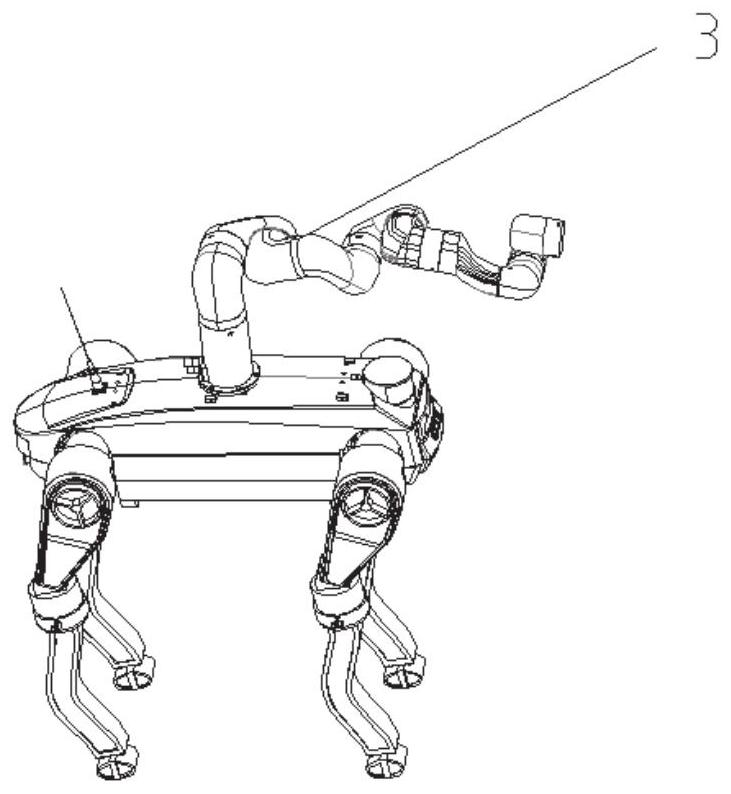

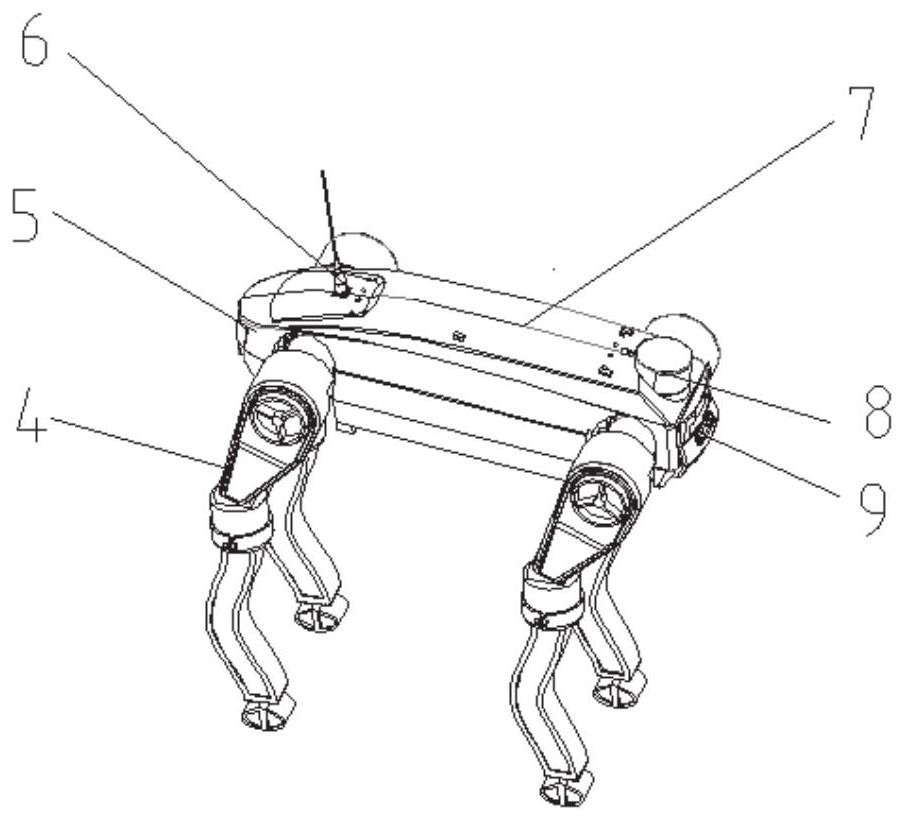

[0111] A substation legged robot comprising a robot platform, a detection assembly, a rotatable outrigger, a robotic arm and a control unit, wherein:

[0112] A plurality of rotatable outriggers are arranged under the robot platform to carry and drive the robot platform to move, and a connecting part is arranged on the robot platform, and the connecting part is detachably linked with the detection component or / and the mechanical arm, The mechanical arm is used to perform maintenance tasks, and the detection component is used to perform detection tasks;

[0113] Each rotatable outrigger is equipped with an independent drive, and the control unit controls the action of each drive or / and the mechanical arm according to the obstacles on the site, and adjusts the posture of the robot platform or / and the mechanical arm to meet the walking of different tasks Require.

[0114] The legged robot platform adopts a unified interface form. The pan-tilt detection component and the robotic ...

Embodiment 2

[0142] Based on the substation legged robot in Embodiment 1, a multi-robot joint inspection system is provided, including several substation legged robots, substation wheeled robots and a central processing unit, wherein:

[0143] The substation legged robot conducts inspections in the first area, and the substation wheeled robot performs inspections in the second area, and both the first area and the second area have multiple inspection points;

[0144] The central processor communicates with the substation legged robots and substation wheeled robots, receives the inspection information obtained by all the robots at the corresponding inspection points, and is configured to analyze the inspection information, locate the power equipment and identify the location of the power equipment. state.

[0145] As an optional implementation, the inspection range formed by all the inspection points in the first area and the second area can cover the entire substation inspection area;

[...

Embodiment 3

[0152] A substation legged robot operation method, comprising the following steps:

[0153] When inspection is required, according to the obstacles on site, control the robot to reach the designated position, adjust the posture of the robot, and use the detection components to perform detection tasks on the corresponding substation equipment;

[0154] When maintenance is required, install the robotic arm, adjust the posture of the robot, and perform maintenance tasks.

[0155] According to the obstacles on the site, control the robot to reach the designated position and adjust the robot's posture. When the legged robot is walking, the legs are divided into supporting legs and swinging legs according to the supporting state. The supporting legs push the ground, and the feet move backward to push the trunk. Proceed; swing leg soars forward in preparation for touchdown. Wherein, the swinging stage of the swinging leg is divided into an ascending stage and a descending stage acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com