125DEG C temperature-resistant ultraviolet crosslinked polyethylene insulating material and preparation method thereof

A technology of cross-linked polyethylene and ultraviolet light, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., and can solve problems such as failure to meet application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

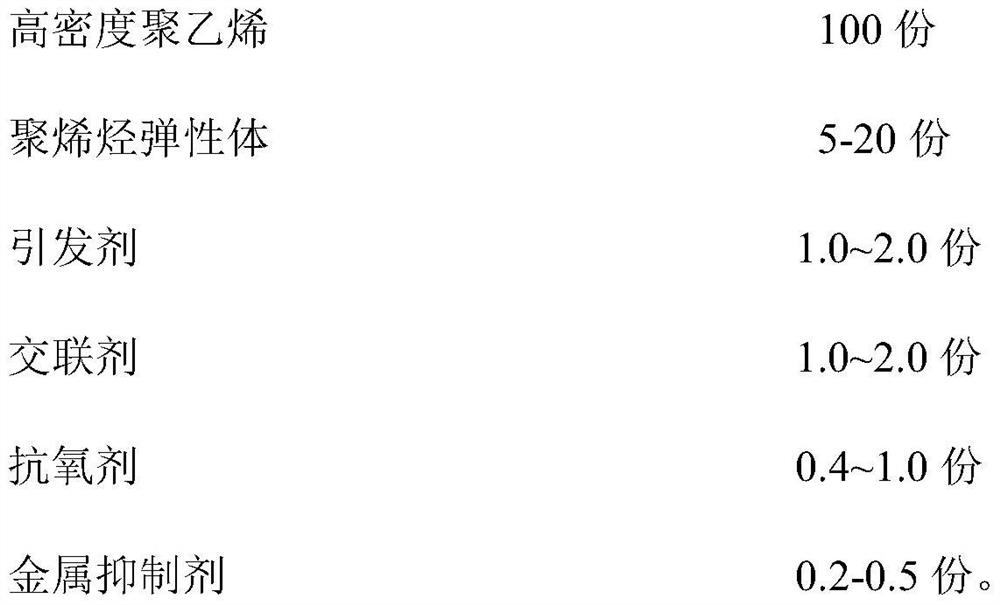

[0019] Use the following materials and the method disclosed in the present invention to prepare a temperature-resistant 125°C UV cross-linked polyethylene insulating material:

[0020]

Embodiment 2

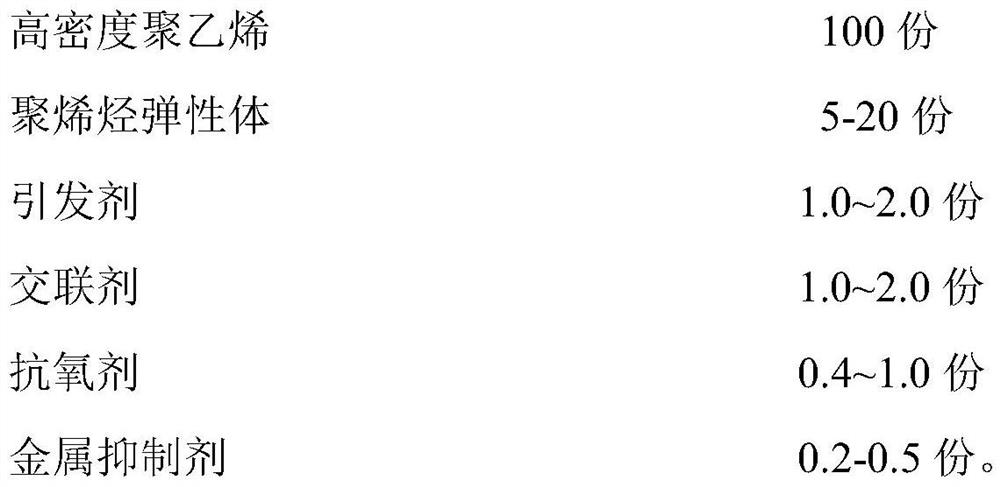

[0022] Use the following materials and the method disclosed in the present invention to prepare a temperature-resistant 125°C UV cross-linked polyethylene insulating material:

[0023]

Embodiment 3

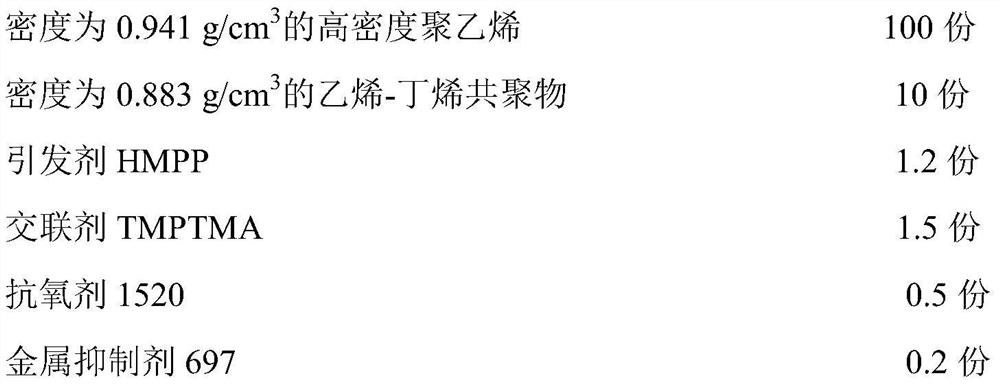

[0025] Use the following materials and the method disclosed in the present invention to prepare a temperature-resistant 125°C UV cross-linked polyethylene insulating material:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com