Reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and reactive technology, which is applied in the field of materials, can solve problems such as adverse effects on hot-melt adhesive performance, generation of bubbles, and performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

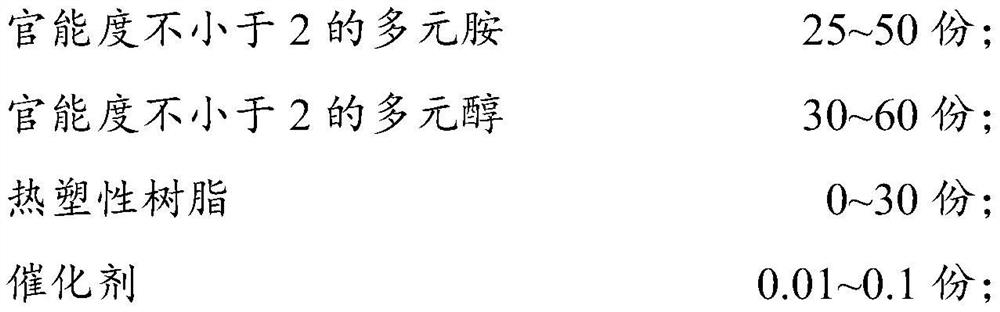

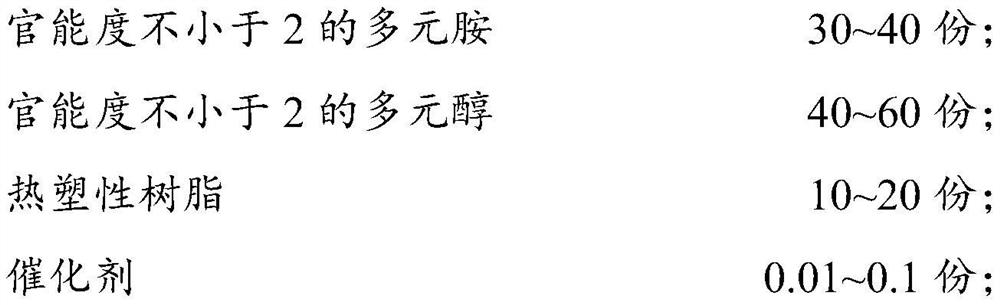

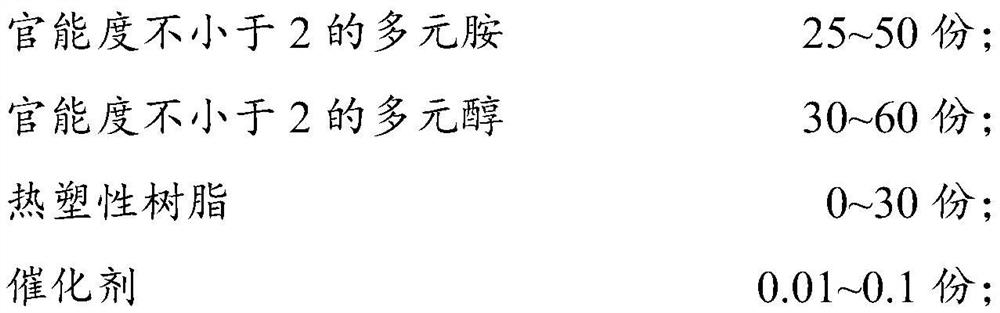

Method used

Image

Examples

preparation example Construction

[0070] Preparation of Component A: Stir and mix the polyol, thermoplastic resin, catalyst and additives at a temperature of 105°C. After the mixture turns into a liquid at high temperature, stir under reduced pressure to remove the water contained in the mixture. After the water content is lower than 200ppm, dry nitrogen with a purity of 99.9% is passed through to restore the normal pressure of the reactor, and it is stored at room temperature under the isolation of moisture.

[0071] Preparation of Component B: Stir the polyol under reduced pressure at a temperature of 105°C to remove the moisture contained in the material. When the moisture content is lower than 200ppm, pass dry nitrogen with a purity of 99.9% to restore the reactor to normal pressure. , and add polyisocyanate, after reacting for 50 minutes, add additives, and then pass dry nitrogen with a purity of 99.9% to restore the normal pressure of the reactor after degassing under reduced pressure again, and store it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com