Rail transit obstacle removing device

A barrier-removing device and rail transit technology, applied in the field of rail transit, can solve the problems of manual adjustment, weak engine operation, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

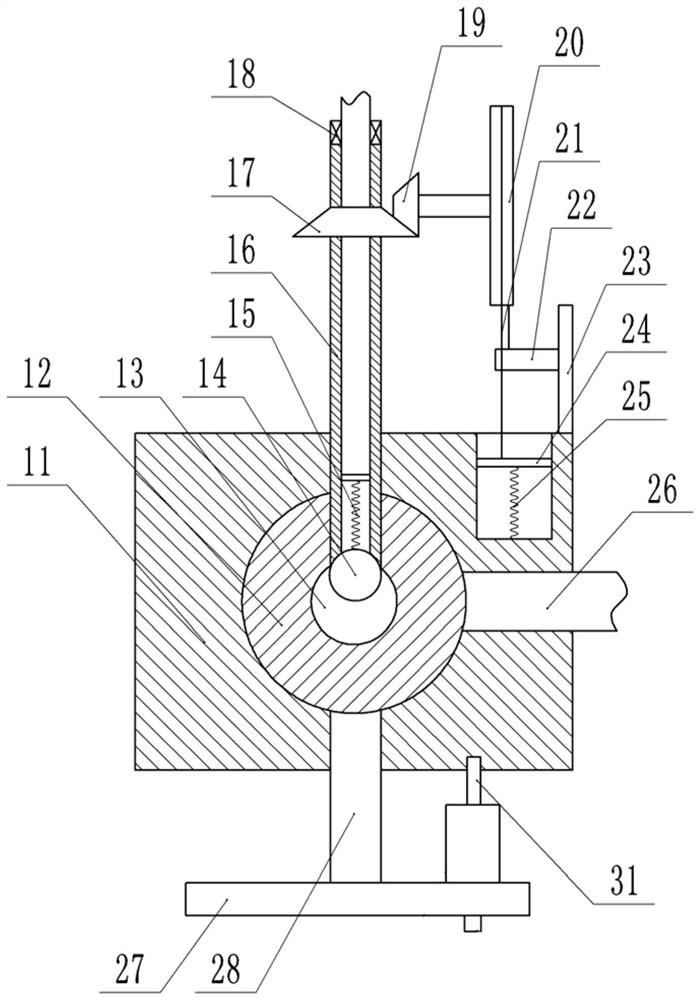

[0018] Basic as attached figure 1 Shown: rail transit obstacle removal device, which can be specifically a repair vehicle, including a fuel system, which includes a fuel tank, an oil filter, a fuel pump, a one-way valve, an engine, a solenoid valve, a throttle valve, and a fuel pipeline. This implementation The fuel system in the example belongs to the prior art and is used to drive the wrecker to work. It is relatively common in existing wreckers, construction cranes and automobiles that use fuel as power, and will not be repeated here. In this embodiment, the throttle valve in the fuel system is mainly improved, specifically: the throttle valve includes a housing 11, a ball cavity is provided in the housing 11, a ball 12 is connected to the ball cavity in rotation, and the ball 12 is provided with There is an oil hole 13, and the housing 11 is provided with a horizontally arranged oil outlet 26 and two vertical passages, the two passages are respectively located on the upper...

Embodiment 2

[0026] The difference between the embodiment and the embodiment 1 is that, on the basis of the embodiment 1, only the positions of the two ends of the stay cord 21 are exchanged, that is, the end of the stay cord 21 connected to the weight 22 in the embodiment 1 is now connected to the piston. 24 is connected, and the end that stay cord 21 is connected with piston 24 is connected with weight 22 at this moment. In this way, when the weight 22 slides, the direction of rotation of the adjusting disc 20 is opposite to that of Embodiment 1, so that the angle between the oil hole 13 on the ball 12 and the oil outlet 26 becomes smaller after the working altitude of the device becomes higher. , the degree of communication between the oil hole 13 and the oil outlet passage 26 becomes larger, so that the flow rate of fuel entering the oil outlet passage 26 becomes larger. When the working altitude of the device becomes lower, the angle between the oil hole 13 on the sphere 12 and the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com