Stationary pollution source waste gas circulating fluidized bed type mercury sampling bottle

A circulating fluidized bed, fixed pollution source technology, applied in sampling, sampling device, measuring device and other directions, can solve the problems of inability to work, low efficiency, increased pressure drop along the way, etc., to ensure the representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

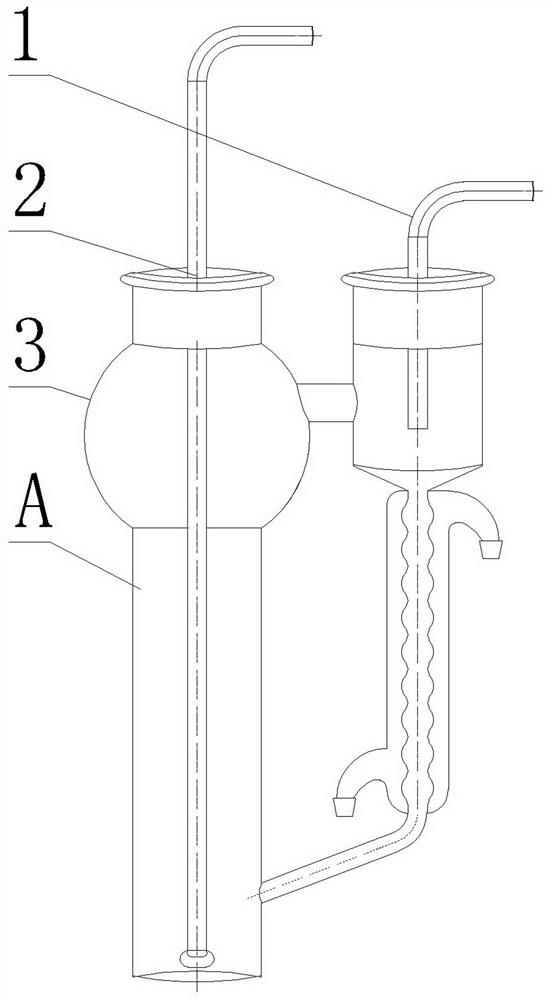

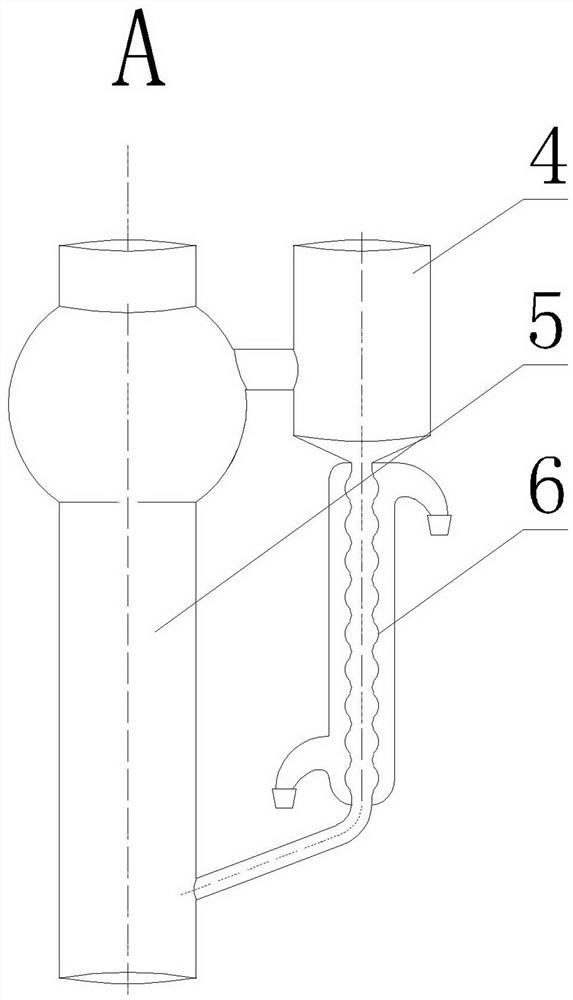

[0016] Such as figure 1 , figure 2 As shown, the fixed pollution source waste gas circulating fluidized bed mercury sampling bottle is characterized in that it includes a plugged gas outlet pipe 1, a plugged gas inlet pipe 2, and a circulating fluidized bed mercury sampling bottle body 3. The circulating fluidized The bed-type mercury sampling bottle body 3 includes a cyclone cone cylinder 4, a circulating fluidized bed cylinder body 5, a spherical condensation descending return pipe 6, and the outer sleeve of the spherical condensation descending return pipe 6 continues to flow ice water at 0-4°C. The outlet pipe 1 and the cyclone cone 4 form a cyclone separator. The tangential inlet of the cyclone cone 4 is connected to the upper part of the circulating fluidized bed cylinder 5. The bottom of the cyclone cone 4 is designed with a spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com