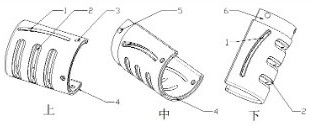

Preparation method of degradable porous ulna middle-end fracture bone connector

A technology of bone fitting and size, applied in the field of medical devices, can solve the problems of loose fixation, easy needle withdrawal, and large bone damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

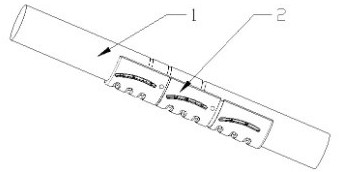

[0027] The first step: prepare metal nano-mixed powder, mix the metal titanium, magnesium, zinc, and strontium according to the mass fraction of titanium-40%, zinc-4%, strontium-0.5%, and magnesium-the balance, and then put it into an energy ball mill for processing Ball milling to obtain a powder with a diameter of 150-180nm.

[0028] The second step: prepare hydroxyapatite-polylactic acid composite powder, prepare hydroxyapatite and polylactic acid with a mass ratio of (14-16): (84-86), and mix polylactic acid at 60°C Put it into chloroform and stir until it is fully dissolved, at the same time slowly add hydroxyapatite powder and 5-8% glass fiber during the stirring, use electromagnetic stirring until the hydroxyapatite is completely dispersed evenly, and dry the solution to obtain The samples were placed in a low-temperature environment for 48 hours, and then put into a ball mill to be processed into a composite powder with a diameter of 150-180 nm.

[0029] The third ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com