Hollow bamboo round stick pressing machine

A technology of hollow bamboo and round sticks, which can be used in wood compression, mechanical equipment, sugarcane machining, etc. It can solve the problems of low bending strength, consumption of raw bamboo, and high production costs, so as to reduce weight and improve shear resistance , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

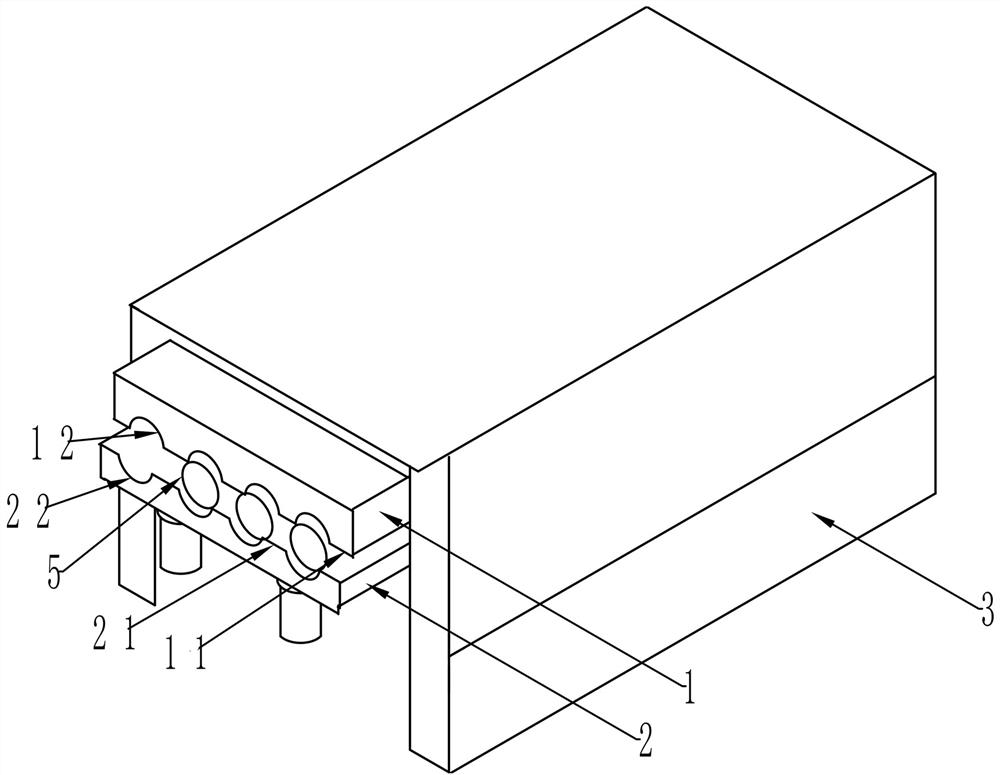

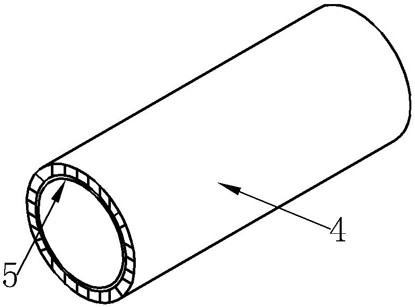

[0025] see Figure 1-2 : a kind of hollow bamboo round stick press machine, comprise frame 3, be provided with first hot-press plate 1 and second heat-press plate 2 in frame 3, the cross-section of first heat-press plate 1 bottom surface 11 is provided with several The semicircular groove 12 and the cross-section of the surface 21 of the second hot pressing plate 2 are provided with a plurality of semicircular grooves 22 of the same size, and the inner mold 5 is arranged between the groove 12 and the groove 22 .

[0026] The outer diameter of the inner circle mold 5 is less than the hollow bamboo round stick 4 internal diameter 1-5mm made, preferably with 3mm. The thickness of the inner circle mold is 2-10mm, and the length is equal to the made hollow bamboo round stick 4. Inner circle mold 5 is hollow steel pipe or solid log.

[0027] The cross section of the semicircular groove 12 on the bottom surface 11 of the first heat press plate 1 and the corresponding semicircular g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com