Outburst elimination method for outburst coal seam based on controllable shock wave permeability improvement

A technology of outburst coal seam and shock wave, which is applied in the outburst elimination field of outburst coal seam based on controllable shock wave anti-reflection, can solve the problems of easy hole collapse, poor suction effect, high use cost, etc., to reduce risk, pipeline installation and post-production Reduced maintenance costs and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing.

[0058] A method for eliminating outbursts in outburst coal seams based on controllable shock wave anti-reflection, comprising the following steps:

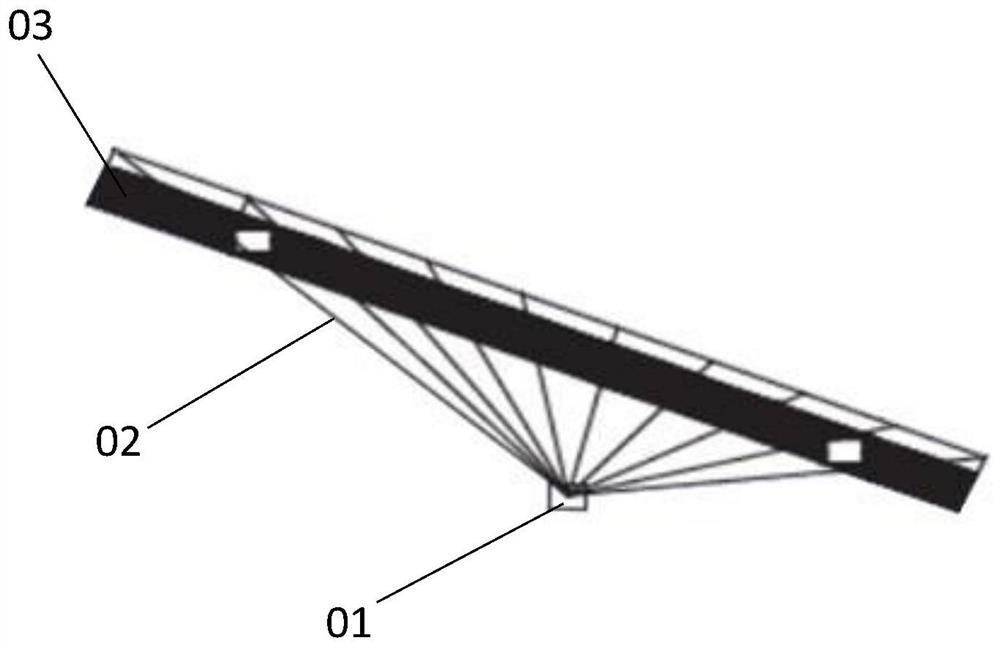

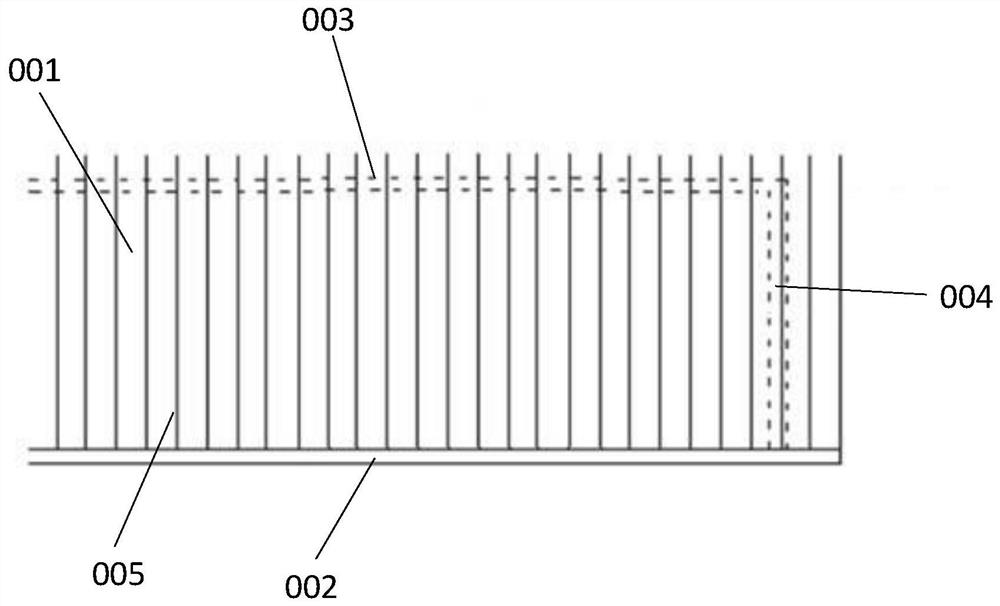

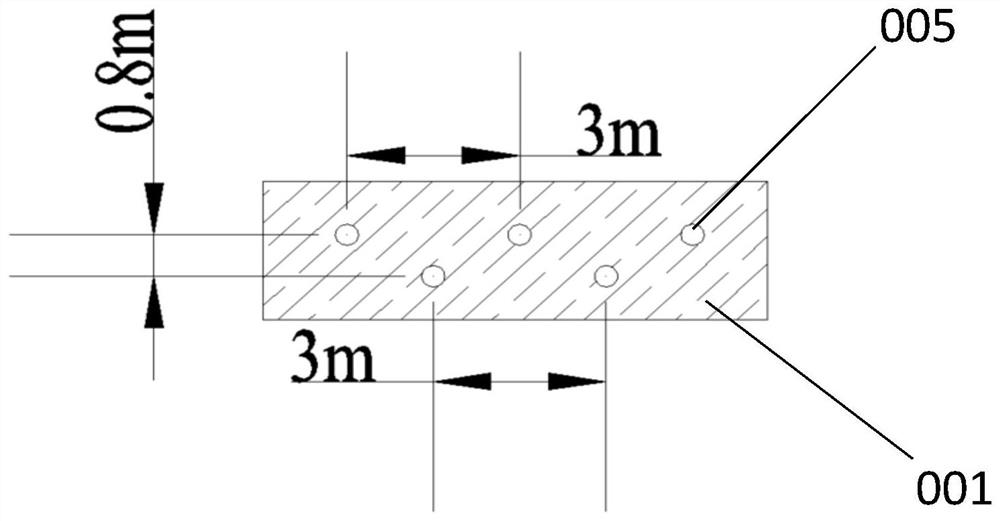

[0059] 1) A first drilling site is set at the head of the preset roadway 2 on one side of the outburst coal seam 1 to be mined, and the anti-reflection drilling 3 is drilled along the tunneling direction of the preset roadway 2 on one side in the first drilling site; The depth of the anti-reflection borehole 3 used for shielding excavation is 150-210m;

[0060] 2) Use the controllable shock wave generating equipment 9 to perform shock wave anti-reflection operation on the anti-reflection borehole 3 for cover excavation, and then drain the gas in the hole until the gas pressure in the hole drops below 0.74 MPa, and the gas content per ton of coal drops to 6 -8m 3 Below (the specific value within this range shall be determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com