Manufacturing process of corrugated micro-electrostatic module

A manufacturing process and micro-electrostatic technology, which is applied in the field of electrostatic module manufacturing process, can solve the problems of high cost, complicated manufacturing of micro-electrostatic modules, high temperature resistance, poor flame retardant performance, etc., and achieves good workability, stable overall structure, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] A manufacturing process of a corrugated micro-static module, comprising the following steps:

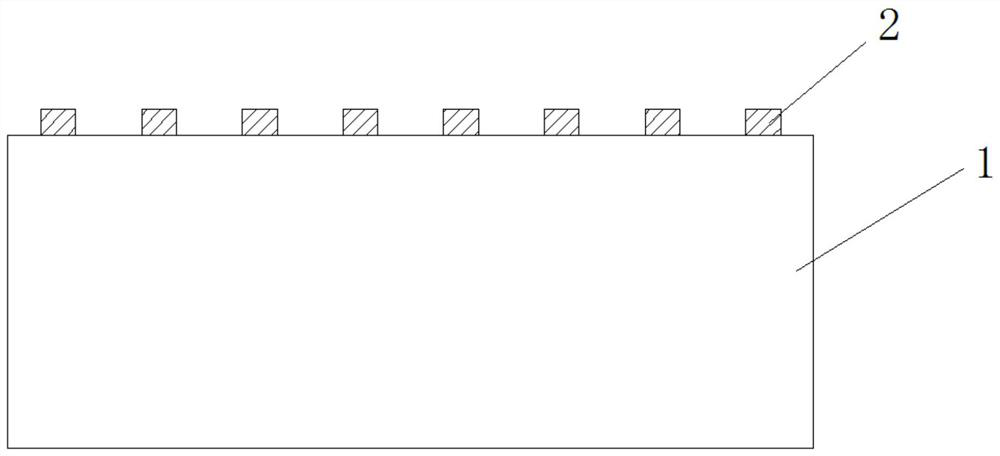

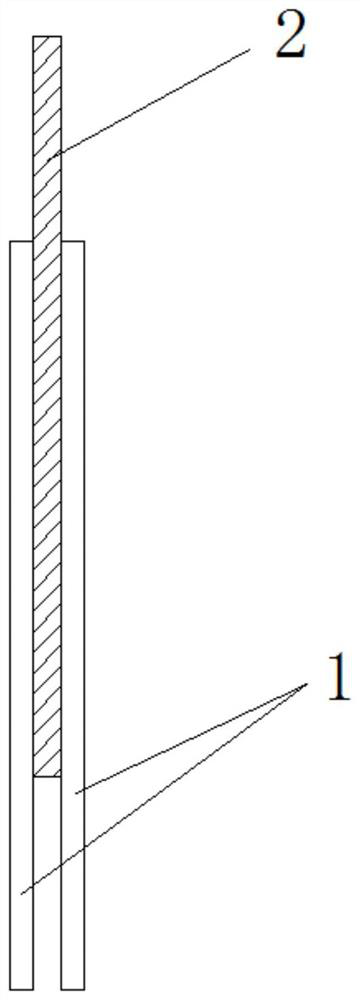

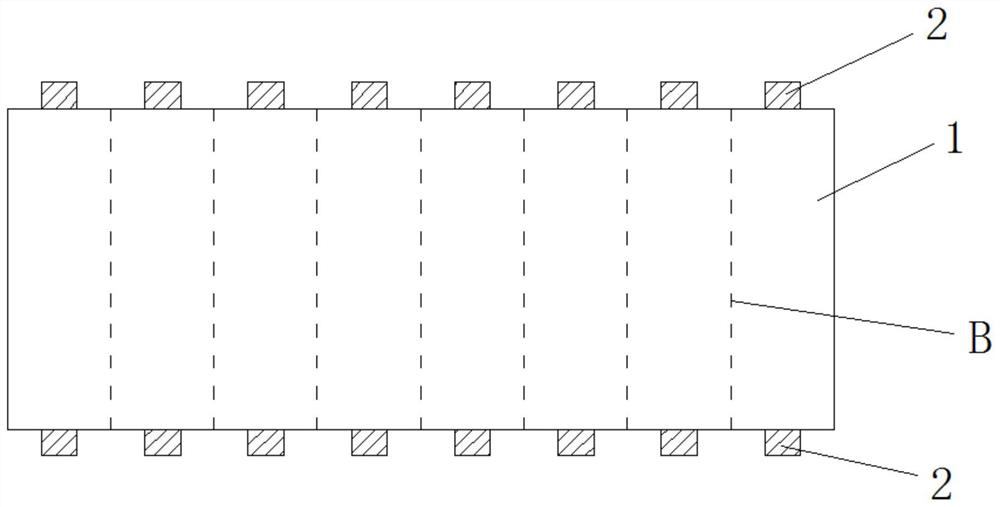

[0037] S1. Electrode sheet production, glue a number of conductive sheets 2 on the upper surface of the flexible electrode sheet substrate 1 at equal intervals, one end of each conductive sheet 2 protrudes from the upper edge of the upper surface of the flexible electrode sheet substrate 1 by 1 to 3 cm, and the other end is connected to the upper surface of the flexible electrode sheet substrate 1. Leave a distance of 1 to 3 cm between the upper surface and the lower edge of the flexible electrode substrate 1. After bonding, apply high-temperature-resistant and flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com